Throttling adjusting system of cogeneration turbine unit and method of ordering power by heat

A technology for adjusting systems and steam turbine units, which is applied in mechanical equipment, engine components, machines/engines, etc., and can solve the problem of high limit setting value of extraction butterfly valve, inability to guarantee measurement accuracy, and inability to achieve thermostatic electricity for thermoelectric units, etc. problem, to achieve the effect of high flow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

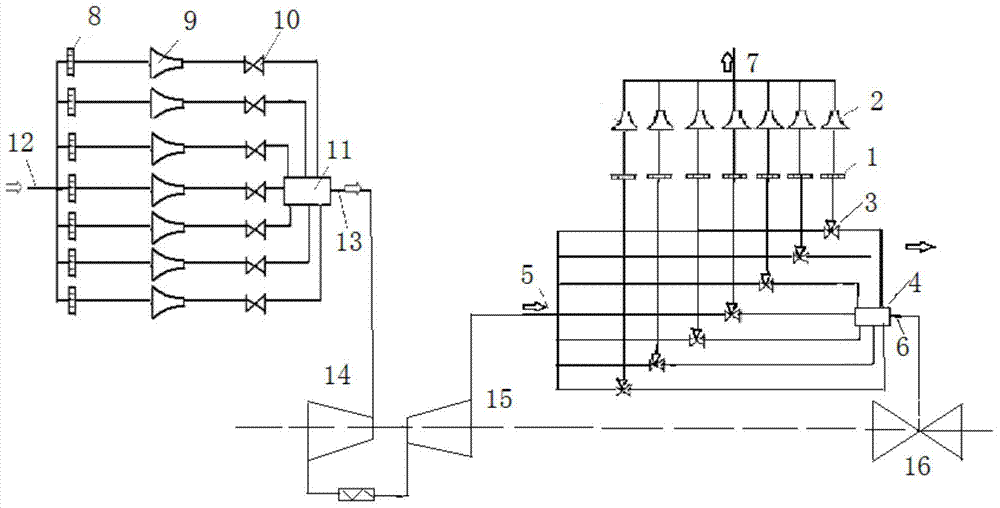

Method used

Image

Examples

Embodiment 1

[0048] For a subcritical 300,000-kilowatt pure condensing unit, the power plant entrusted the manufacturer to carry out the transformation using the national coal-fired unit comprehensive upgrading and transformation fund. The high-pressure cylinder removed the regulating stage, and the steam distribution mechanism was developed based on the patented technology (Patent No. ZL201320280254.4) throttle valve system. The associated steam extraction adjustment valve is installed on the medium and low pressure connecting pipe. The heat consumption rate of the rated working condition assessment test before the transformation was 8105, and the measured heat consumption rate of the pure condensing condition after the transformation was 7950kJ / kWh, the efficiency of the high-pressure cylinder reached 86%, and the pressure loss of the steam distribution mechanism was less than 0.5%. The design value has been achieved after transformation; especially at 60% low load, the unit operates at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com