Injection molding filling machine and working method thereof

A filling machine and forming device technology, applied in the direction of packaging, transport packaging, multiple packages, etc., can solve the problems of many and complex procedures in the bottle filling production line, and high cost of bottle filling, so as to improve filling efficiency and The effect of high installation quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

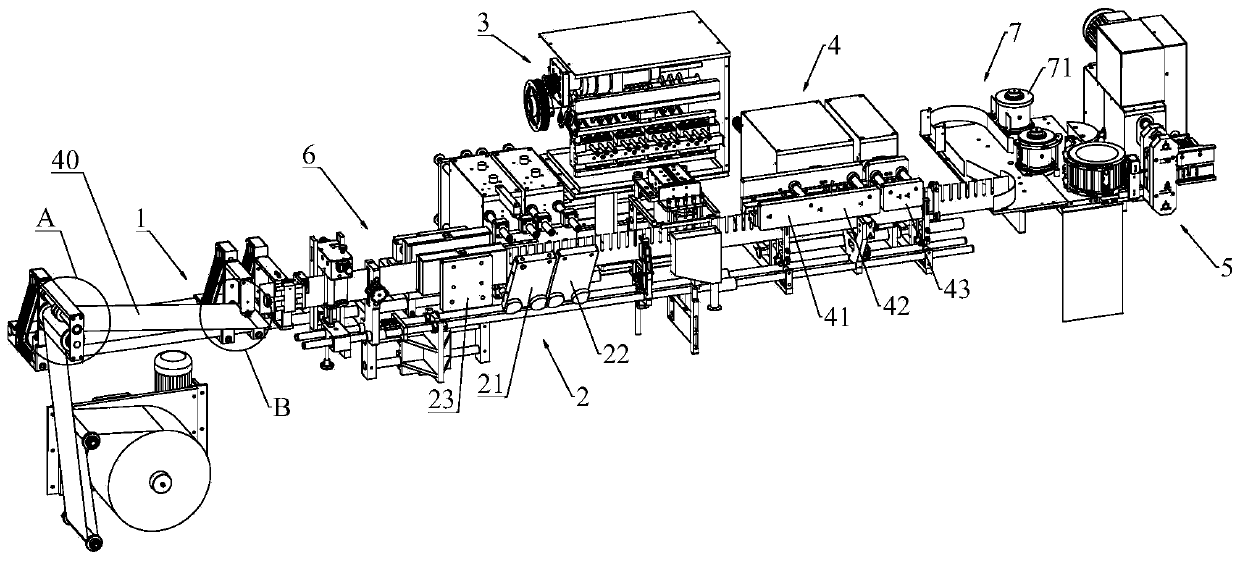

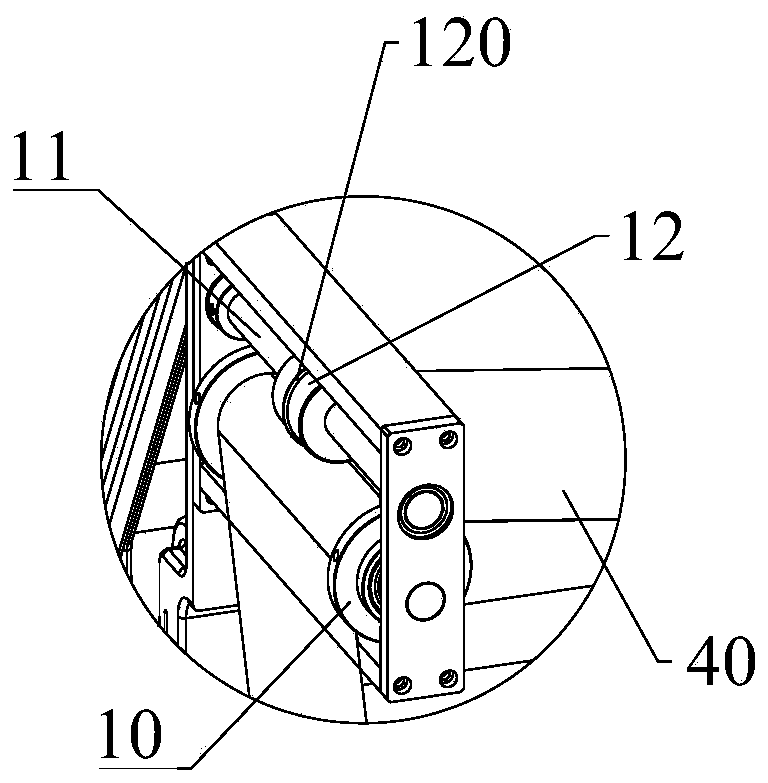

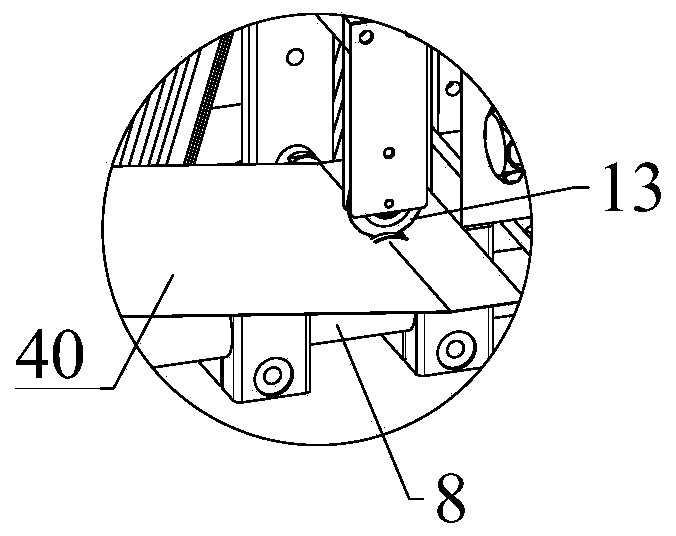

[0041] Such as Figure 1 to Figure 3 As shown, the present embodiment 1 provides an injection molding and filling machine, including: a control module, and a pretreatment device 1 controlled by the control module, a cavity forming device 2, a filling device 3, a top seal forming device 4 and Punching and forming device 5; wherein the pretreatment device 1 is suitable for folding the middle part of the released film material so as to facilitate the film material to be folded in half; the cavity forming device 2 is suitable for folding in half according to the body contour of the packaging material The film material is heat-sealed, and the heat-sealed area is blown to form a packaging material cavity with an opening; the filling device 3 is suitable for filling the packaging material cavity with liquid agent; the top sealing molding The device 4 is suitable for heat sealing the opening of the packaging material filled with the agent liquid to form a complete bag packaging materi...

Embodiment 2

[0104] On the basis of Example 1, this Example 2 provides a working method of an injection molding filling machine, including: using a pretreatment device to press and fold the middle part of the released film material so as to facilitate the film material to be folded in half; The forming device heat-seals the folded film material according to the body contour of the packaging material, and blows air into the heat-sealed area to form a packaging material cavity with an opening; the filling device is suitable for filling into the packaging material cavity Filling with agent liquid; heat-sealing the opening of the packaging material filled with agent liquid through the top sealing forming device to form a complete bag packaging material; and cutting the film strip according to the preset number of bag packaging materials through the punching forming device Bag packaging unit.

[0105]Specifically, the specific structures and working principles of the pretreatment device, the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com