High sphericity Cr base alloy-tib 2 Micronano powder and preparation method thereof

A high sphericity, base alloy technology, applied in the direction of metal processing equipment, energy efficiency, process efficiency, etc., can solve the problems of large particle size distribution gap, poor bonding strength, poor fluidity, etc., to achieve small particle size gap , Enhance hardness, increase ductility and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

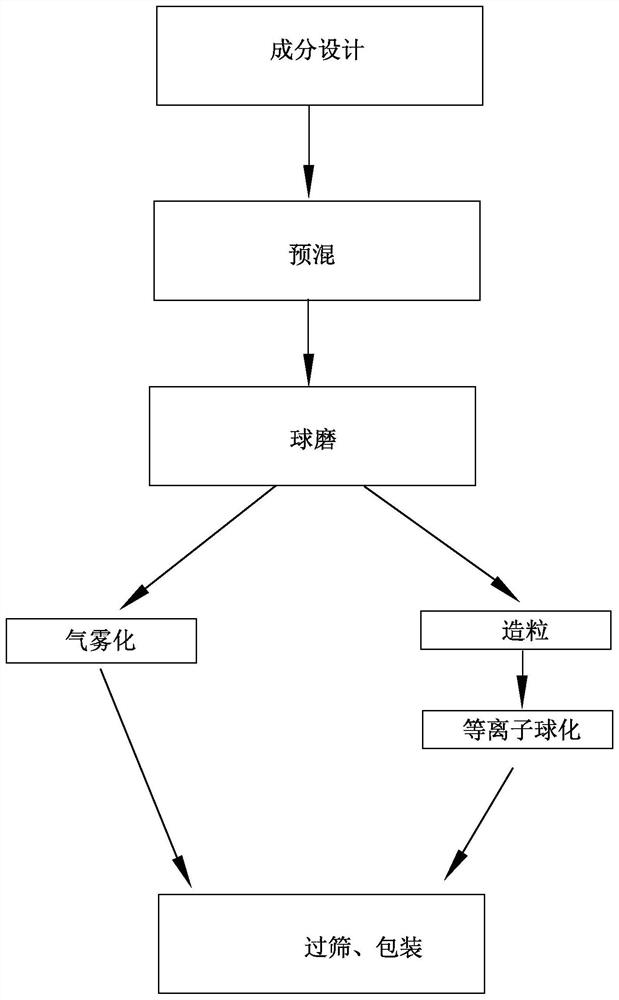

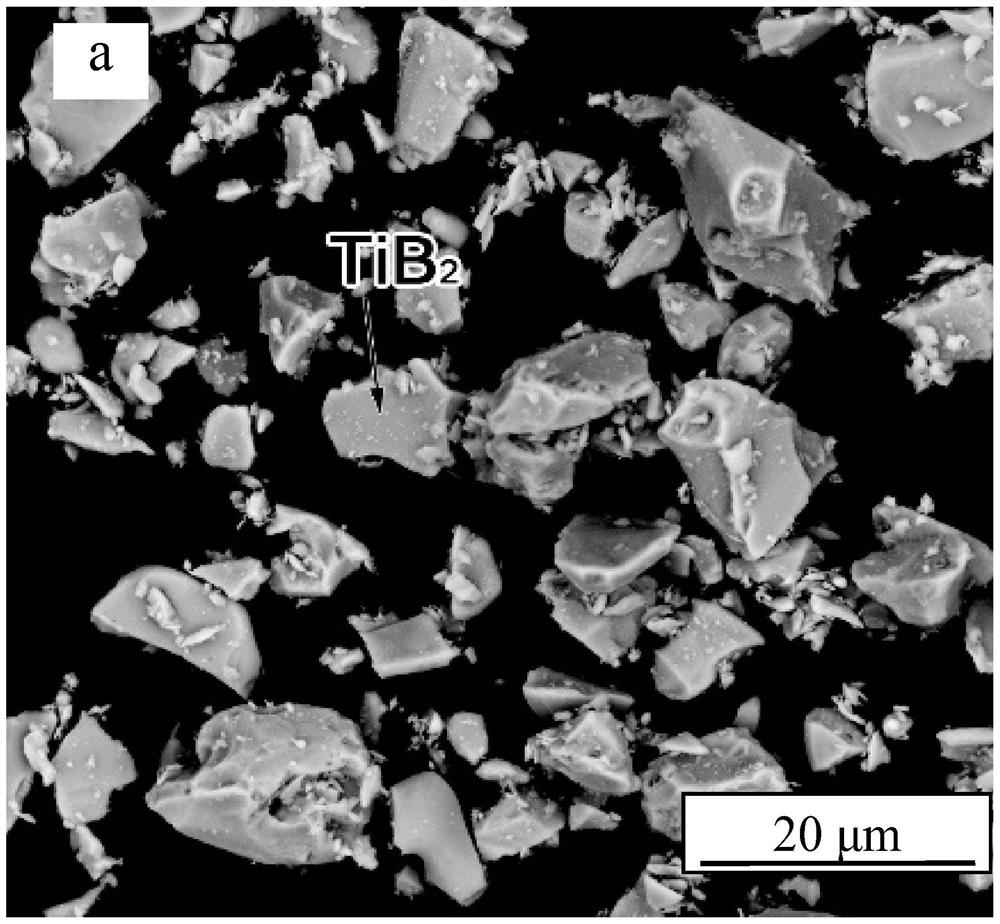

[0037] Example 1: See attached figure 1 to attach Figure 7 , this embodiment provides a high sphericity Cr-based alloy-TiB 2 Micro-nano powder, including nano-sized TiB 2 Powder and Cr-based alloy powder, by mass percentage, the nanoscale TiB 2 The percentages of the powder and the Cr-based alloy powder in the total mass of the micro-nano powder are respectively:

[0038] nano-TiB 2 Powder 45%;

[0039] Cr-based alloy powder 55%,

[0040] The Cr-based alloy powder is CoCr alloy powder, and the percentages of each element in the CoCr alloy powder to the CoCr alloy powder are: Co 53.2%, Cr 46.8%.

[0041] High Sphericity Cr-Based Alloy-TiB According to the Invention 2 The preparation method of the micro-nano powder is the above-mentioned high sphericity Cr-based alloy-TiB of the present embodiment 2 High sphericity Cr-based alloy-TiB produced by the proportioning formula of micro-nano powder 2 Micronano powder. Follow the steps below:

[0042] 1) The Cr-based alloy p...

Embodiment 2

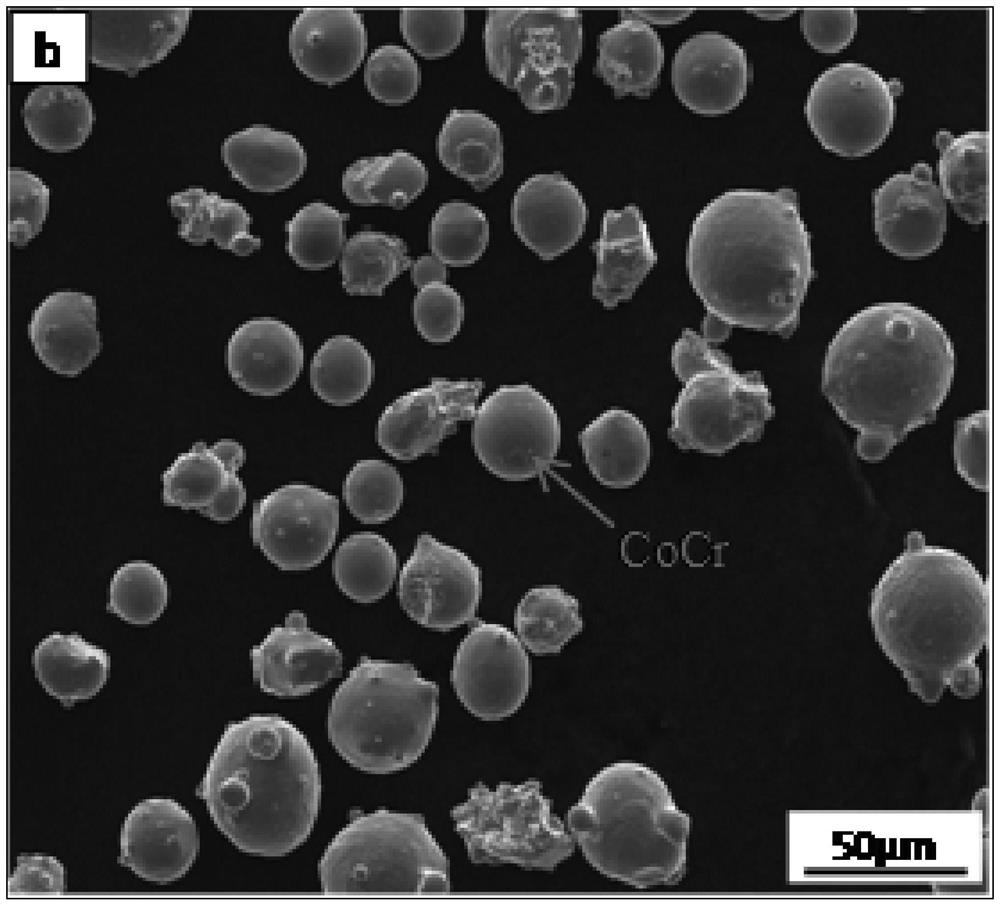

[0047] Embodiment 2: This embodiment provides a high sphericity Cr-based alloy-TiB 2 Micro-nano powder, the high sphericity Cr-based alloy-TiB of the present embodiment and embodiment 1 2 The components and proportions of the micro-nano powders are the same, therefore, the attached figure 2 to attach Figure 4 It can also be used as a drawing of this embodiment, the difference is that step 3 of this embodiment adopts gas atomization treatment to prepare the shown micronano powder. The gas atomization treatment is to melt the second composite powder through electrode induction heating of a vacuum induction gas atomization device, and then break the droplets formed by the melted second composite powder into fine droplets by impacting with a high-pressure inert gas, and Make the small droplets fly and solidify in the atomization tower of the vacuum induction gas atomization equipment to obtain a high-sphericity Cr-based alloy-TiB 2 Micronano powder. The gas atomization treat...

Embodiment 3

[0048] Embodiment 3: This embodiment provides a high sphericity Cr-based alloy-TiB 2 Micro-nano powder, including nano-sized TiB 2 Powder and Cr-based alloy powder, by mass percentage, the nanoscale TiB 2 The percentages of the powder and the Cr-based alloy powder in the total mass of the micro-nano powder are respectively:

[0049] nano-TiB 2 Powder 25%;

[0050] Cr-based alloy powder 75%,

[0051] The Cr-based alloy powder is Ni-Cr-Mo alloy powder, and the percentages of the constituent elements in the Co-Ni-Cr-Mo alloy powder in the Cr-based alloy powder are: Co 39%, Ni 14% , Cr 20%, Mo 8%, Mn1.5%, Fe balance;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com