Novel ultra-wide front fulcrum cable-stayed hanging basket thrust device

A front fulcrum and pulling cable technology, applied in the field of bridge construction, can solve the problem of inability to support hanging baskets, and achieve the effect of simple and clear installation, fixing and dismantling procedures, reducing the laying process, and increasing the construction speed of hanging baskets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

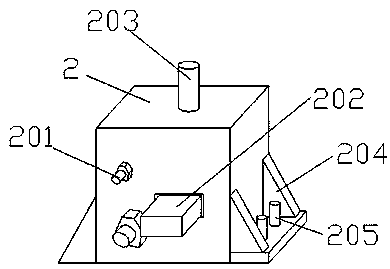

[0034] A new type of super-wide front fulcrum dragline hanging basket thrust device of the present invention is installed on the upper surface of the bridge, which is suitable for the running mechanism of the upper sliding track. The thrust device of this walking mode needs to be provided with a reserved hole on the bridge surface , the first fixed steel bar 203, the second fixed steel bar 205, and the third fixed steel bar 404 can also be directly embedded, and the first fixed steel bar 203 and the second fixed steel bar 205 embedded in the guardrail can be used as guardrail reinforcements in the later stage. The third fixed steel bar 404 in the middle needs to be cut off and roughened.

[0035] The specific structure is as follows:

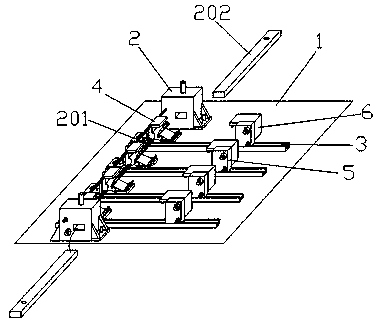

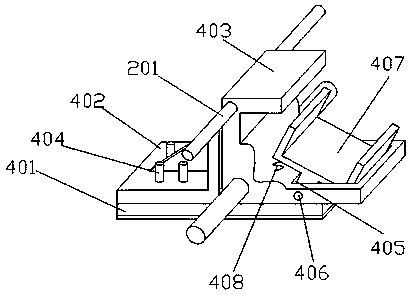

[0036] refer to Figure 1-5 , a new ultra-wide front fulcrum drag cable hanging basket thrust device, including support blocks 2 arranged at the guardrails on both sides of the poured bridge deck 1, fixed support 4 arranged at one side of the end...

Embodiment 2

[0039] A new type of ultra-wide front fulcrum guy cable hanging basket thrust device of the present invention is installed on the lower surface of the bridge, which is suitable for the running mechanism of the lower sliding track. There are not many restrictions on the thrust device of this walking mode, and the reserved hole can Filling through supplementary pouring; if the method of pre-embedded steel bars is adopted, the pre-embedded steel bars can be processed by chiseling and supplementary pouring, and can also be used as reinforcement binding for expansion joints;

[0040] The slight difference in structure between this embodiment and Embodiment 1 is that, when it is installed on the lower surface of the bridge, it is necessary to fix the locking frame 403 on the L-shaped support plate 402 and the anti-skid plate 401 by means of bolt filling welding to form an inaccessible The dismantled fixed support 4.

[0041] According to the specific structure of the embodiment 1-2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com