Pile holding system of underwater pile foundation construction platform

A construction platform and pile foundation technology, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of no position indicating device of the pile holding system, inability to adjust, waste of manpower and resources, etc., so as to shorten preparation time and prevent Impact damage, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

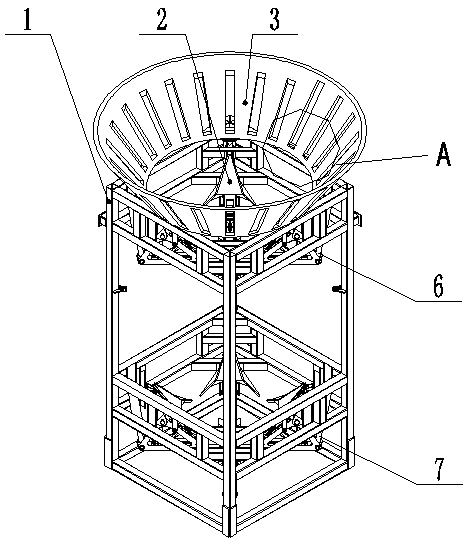

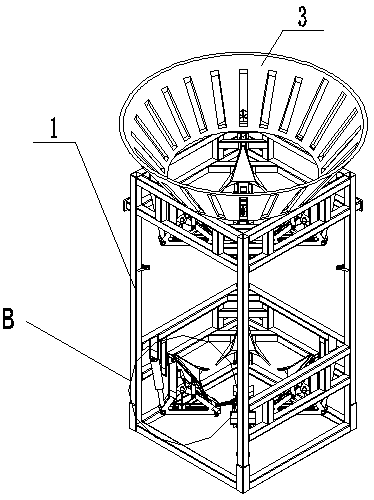

[0022] Such as figure 1 As shown in -7, the pile-holding system of the underwater pile foundation construction platform includes a mounting frame 1, a guide frame 3 and eight connecting rod assemblies 2 for positioning and guiding the foundation pile 8.

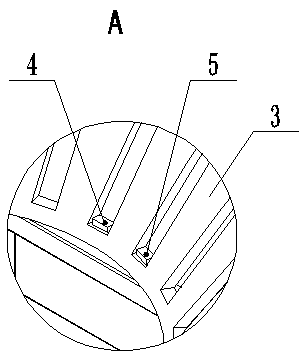

[0023] The mounting frame 1 is a cuboid, and the mounting frame 1 is arranged vertically. The guide frame 3 is a truncated cone with a large top and a small bottom. The guide frame 3 is fixedly connected to the upper end of the mounting frame 1, and the imaging sonar 4 and the laser transmitter are connected to the guide frame 3. 5. The foundation pile 8 is set in the guide frame 3 and the installation frame 1 .

[0024] Eight connecting rod assemblies 2 are all connected to the inside of the installation frame 1, and four of the connecting rod assemblies 2 are respectively connected to the four corners of the middle and upper part of the installation frame 1 to form an upper clamping anti-collision mechanism 6; The rod asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com