Work arm assembly and excavating equipment

A technology of excavation equipment and working arm, which is applied in the field of working arm components, can solve the problems that the working arm cannot fit the side of the roadway and/or the bottom plate, the labor intensity of the workers is high, and the operation effect is not ideal, so as to improve the market competitiveness, Good protection and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

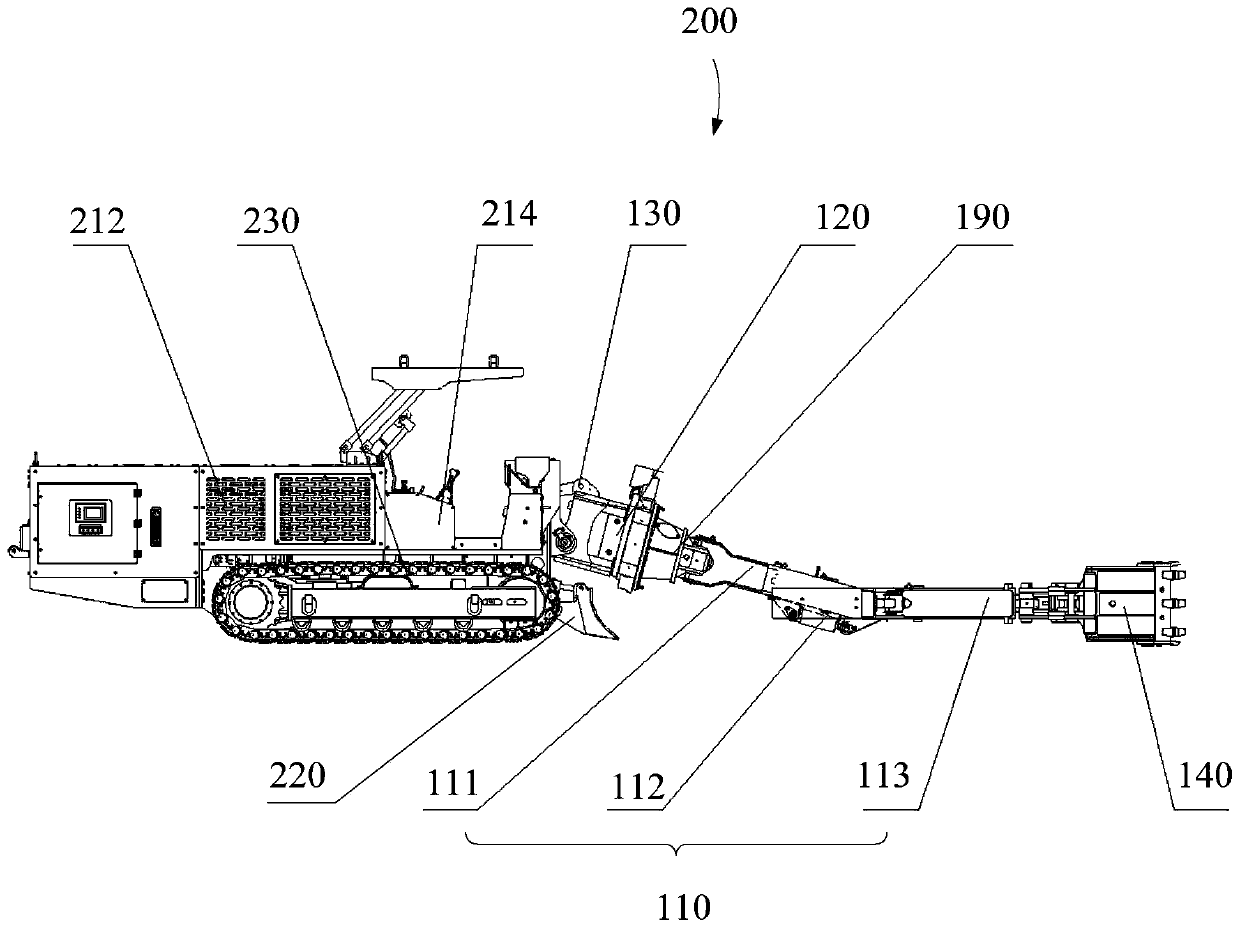

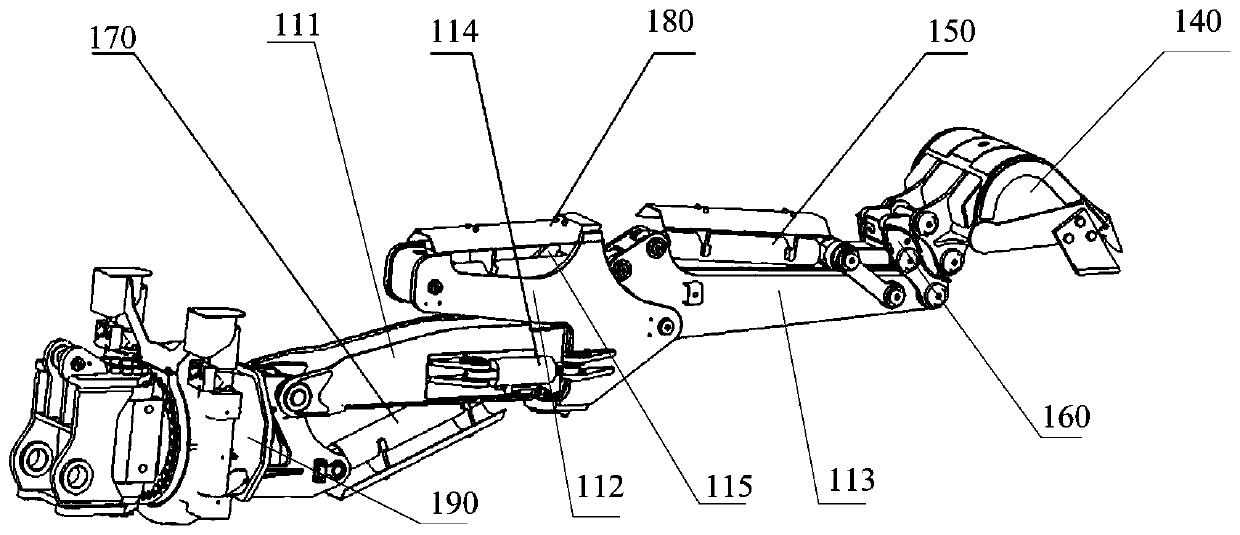

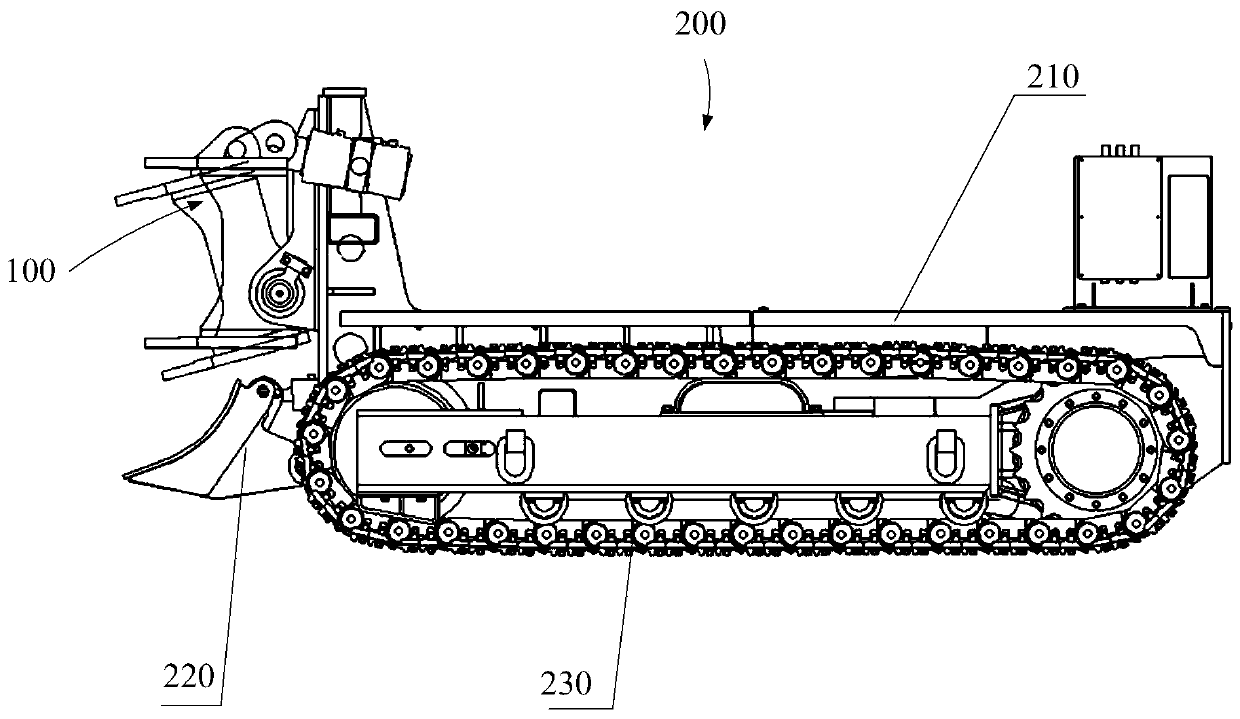

[0050] Such as Figure 1 to Figure 3 As shown, according to the first aspect of the present invention, a working arm assembly 100 is provided, including a working arm 110 , a rotating device 120 and a pitching device 130 .

[0051] Specifically, such as figure 1 with figure 2 As shown, the working arm 110 is used to connect the working device to perform operations on the roadway. The working arm 110 includes a plurality of unit arms and a first hydraulic cylinder 114. The plurality of unit arms are connected in turn, and the first hydraulic cylinder 114 is connected to the plurality of unit arms. two adjacent unit arms, and can adjust the swing angle between the two adjacent unit arms, the pitching device 130 is arranged on the vehicle body of the excavating equipment 200, the pitching device 130 is connected with the rotating device 120, and can be adjusted The first swing angle of the rotating device relative to the pitching device 130, the rotating device 120 is connecte...

Embodiment 2

[0054] Such as Figure 1 to Figure 3 As shown, in an embodiment of the present invention, on the basis of the above-mentioned embodiment 1, further, a plurality of unit arms include a first arm 111, a second arm 112 and a third arm 113 connected in sequence, and the first arm 111 Connected with the rotating device 120, the first hydraulic cylinder 114 connects the first arm 111 and the second arm 112, and can adjust the second swing angle of the second arm 112 relative to the first arm 111; the working arm assembly 100 also includes a second The hydraulic cylinder 115 , the second hydraulic cylinder 115 is connected to the second arm 112 and the third arm 113 , and can adjust the third swing angle of the third arm 113 relative to the second arm 112 .

[0055] In this example, if figure 1 with figure 2 As shown, a plurality of unit arms include a first arm 111, a second arm 112 and a third arm 113 connected in sequence, that is, the second arm 112 is located between the firs...

Embodiment 3

[0058] Such as Figure 1 to Figure 3 As shown, in an embodiment of the present invention, on the basis of the above-mentioned embodiment 2, it further includes: a working device 140 disposed at the end of the third arm 113 away from the second arm 112; a third hydraulic cylinder 150, The third hydraulic cylinder 150 connects the working device 140 and the third arm 113 , and can adjust a fourth swing angle of the working device 140 relative to the third arm 113 .

[0059] In this example, if figure 1 with figure 2 As shown, the working arm assembly 100 also includes a working device 140. The working device 140 is arranged at the end of the third arm 113 away from the second arm 112. The working device 140 is used to perform roadway auxiliary operations, and the working device 140 is connected to the working device 140 through a third hydraulic cylinder 150. and the third arm 113 can adjust the fourth swing angle of the working device 140 relative to the third arm 113, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com