Novel coal mine drill bit

A drill bit, a new type of technology, used in mining equipment, earthwork drilling, construction, etc., can solve the problems of short service life, easy sliding, clogging, etc., and achieve the effect of improving service life and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

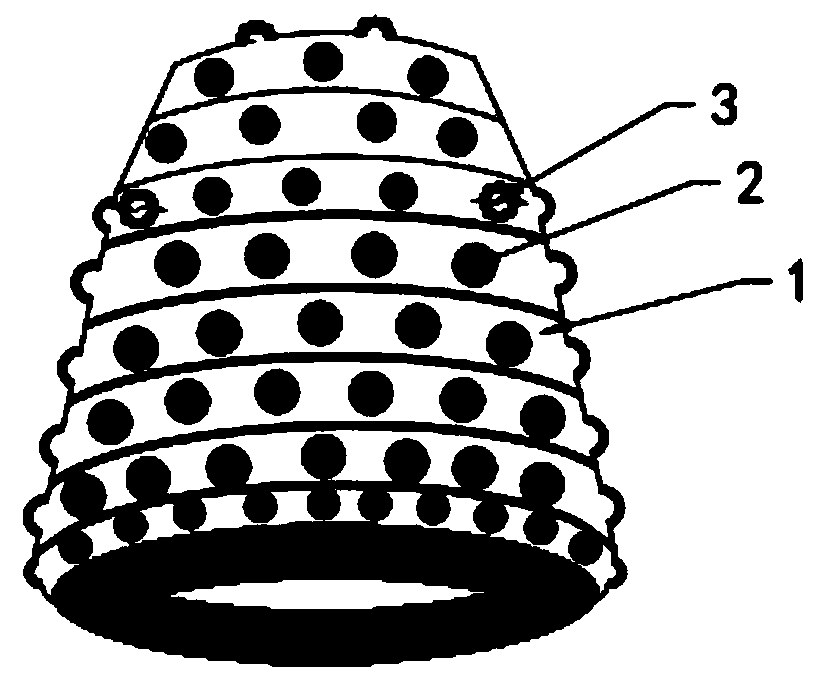

[0025] see figure 1 , the coal mine new drilling drill bit includes a drill bit body 1, the drill bit body 1 is conical with an upper diameter greater than the lower diameter, a plurality of drill teeth 2 are set on the outer surface of the drill bit body 1, and a plurality of water outlet holes are also arranged on the drill bit body 1 3. The water outlet hole 3 is arranged between the two drill teeth 2 .

[0026] A plurality of drill teeth 2 in this embodiment are arranged helically along the outer surface of the drill body 1 . And the diameter of the drill teeth 2 on the top of the drill body 1 is smaller than the diameter of the drill teeth 2 on the bottom of the drill body 1 . The drill bit is matched with ordinary finished drilling rods, and can be processed according to the diameter of the actual used drilling rods, so that it can be used on finished drilling rods of different diameters, and can be used for drilling blastholes in the working face.

[0027] The drill ...

Embodiment 2

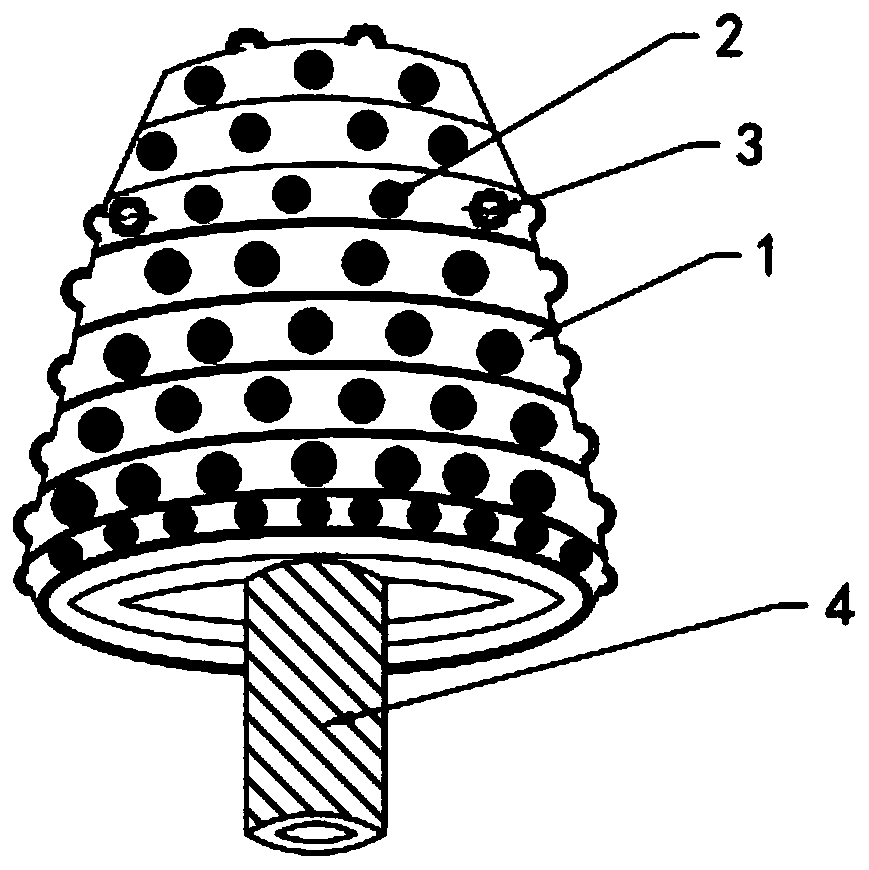

[0030] see figure 2 , The lower end of the drill body 1 is fixed with a connecting screw 4. Further, the connecting screw 4 is a hollow structure, and the inside of the connecting screw 4 communicates with the water outlet hole 3 . The drill bit is matched with the anchor drill rod, which can be used for drilling bolt support in the working face and other parts that need to be drilled. The new coal mine drilling bit of this embodiment has the advantages of convenient connection, more stable structure, long service life and smooth drilling hole wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com