Spin type-magnetic driving downhole cuttings bed clearing tool

A technology for cleaning tools and magnetic transmission, applied in the direction of flushing wellbore, wellbore/well components, earth-moving drilling, etc., can solve the problems of drilling fluid leakage, cleaning tools not running, etc., to achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing.

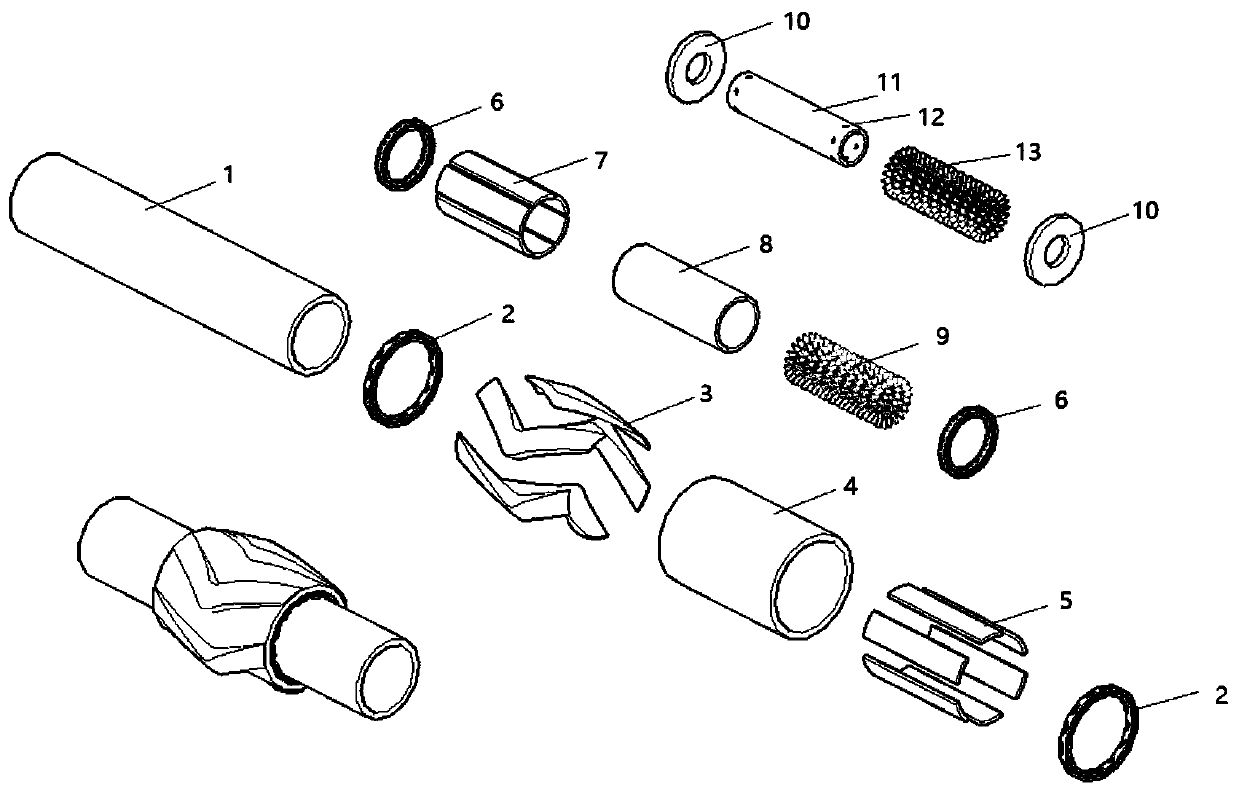

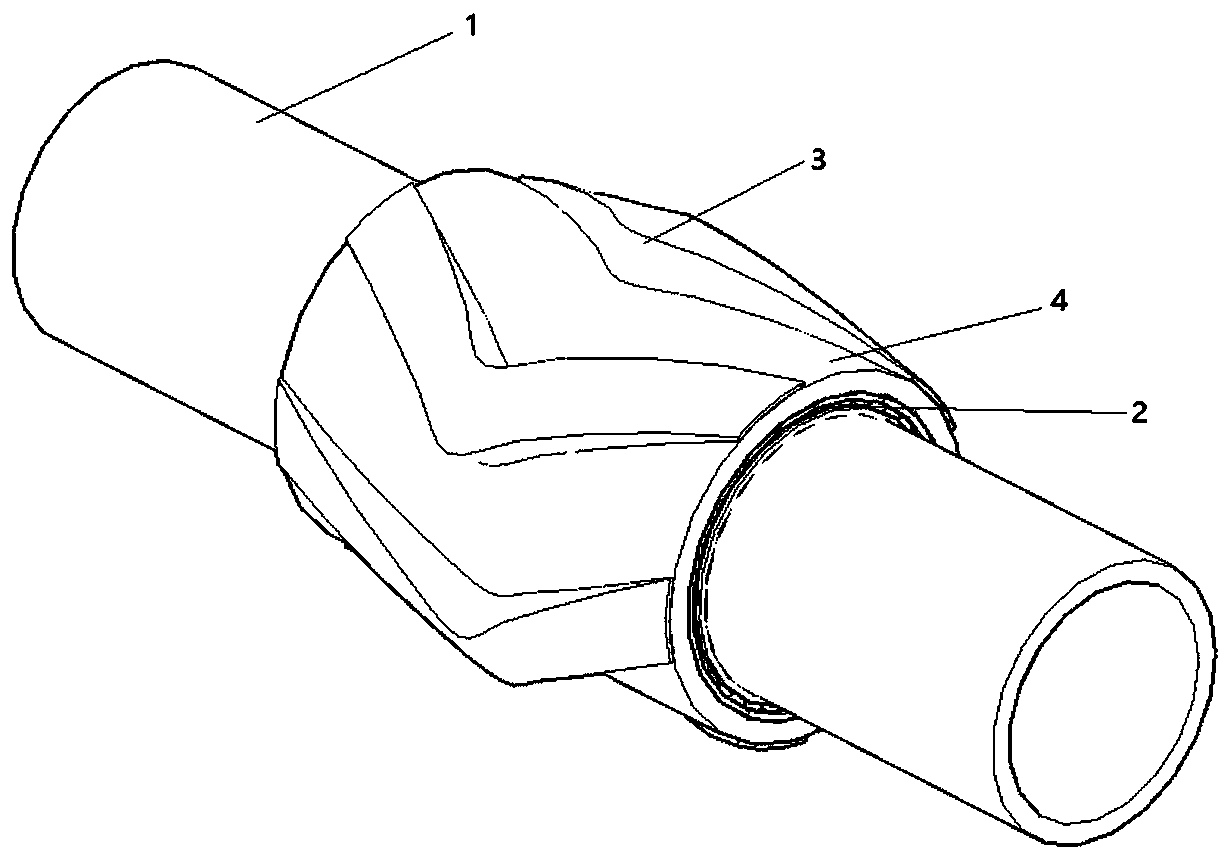

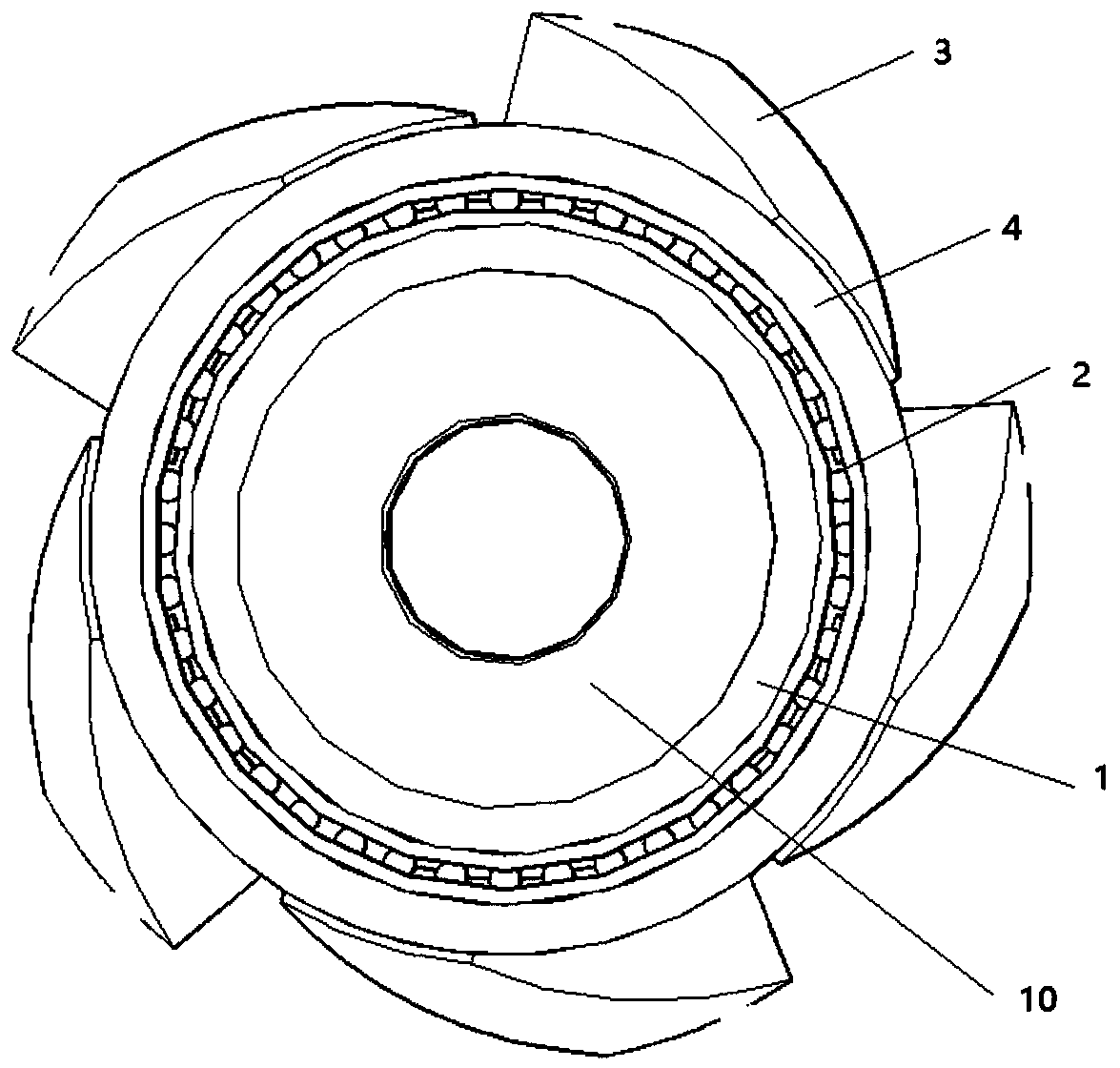

[0026] to combine Figure 1-8 As shown, a spin-magnetic drive downhole cuttings bed removal tool includes a drill pipe body 1, a cutting barrel 4, five micro-V-shaped cutting teeth 3 with gradually changing thickness, and two sets of deep groove balls. The bearings are outer deep groove ball bearings 2 and inner deep groove ball bearings 6, two sets of long permanent magnets are outer long permanent magnets 5 and inner long permanent magnets 7, a rotating cylinder 8, turbine rotor 9 and turbine stator 13 Constituted turbine components, two fixed seats 10 and a fixed cylinder 11.

[0027] The cutting cylinder 4 has five "V"-shaped cutting teeth 3 distributed in an annular array on the outside, and the overall cutting is distributed in an annular shape. During the rotation process, it has a certain disturbing effect on the flow of drilling fluid in the annular space. The turbu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com