A high-precision probe crimping machine

A technology of crimping machine and probe, which is applied in the direction of contact manufacturing, etc., can solve the problems of inability to produce in large quantities, product quality cannot be guaranteed, and affect production capacity, so as to achieve good market promotion prospects, increase production capacity, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Hereinafter, the embodiments of the present invention will be described in detail with examples, so as to fully understand and implement the implementation process of how the present invention uses technical means to solve technical problems and achieve technical effects.

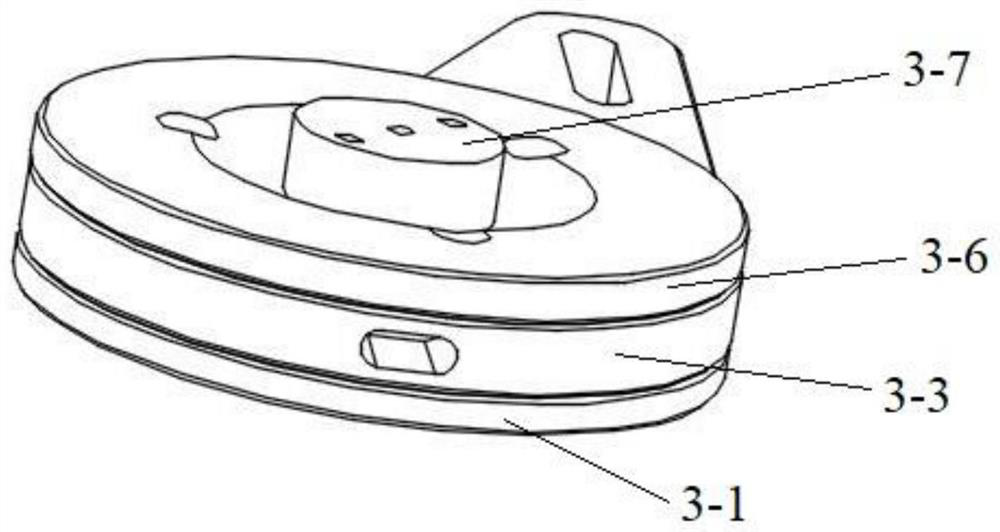

[0034]The invention discloses a high-precision probe crimping machine, which uses a cylinder 4-2 to push the cam 3-3 to sequentially complete the crimping of three high-precision vertical points that are 120° each other. The crimping not only improves the quality of crimping, but also greatly improves work efficiency, and has a very good market promotion prospect.

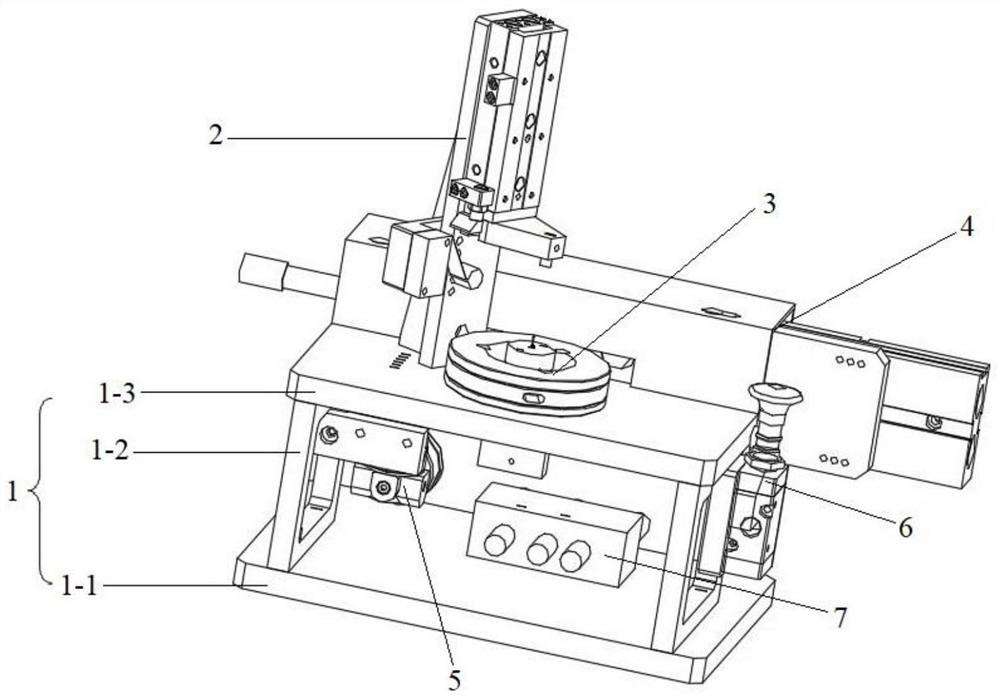

[0035]The structure of the high-precision probe crimping machine disclosed in the present invention is as followsfigure 1 As shown, specifically including:

[0036]A base mechanism 1, plays the role of fastening and supporting the entire equipment;

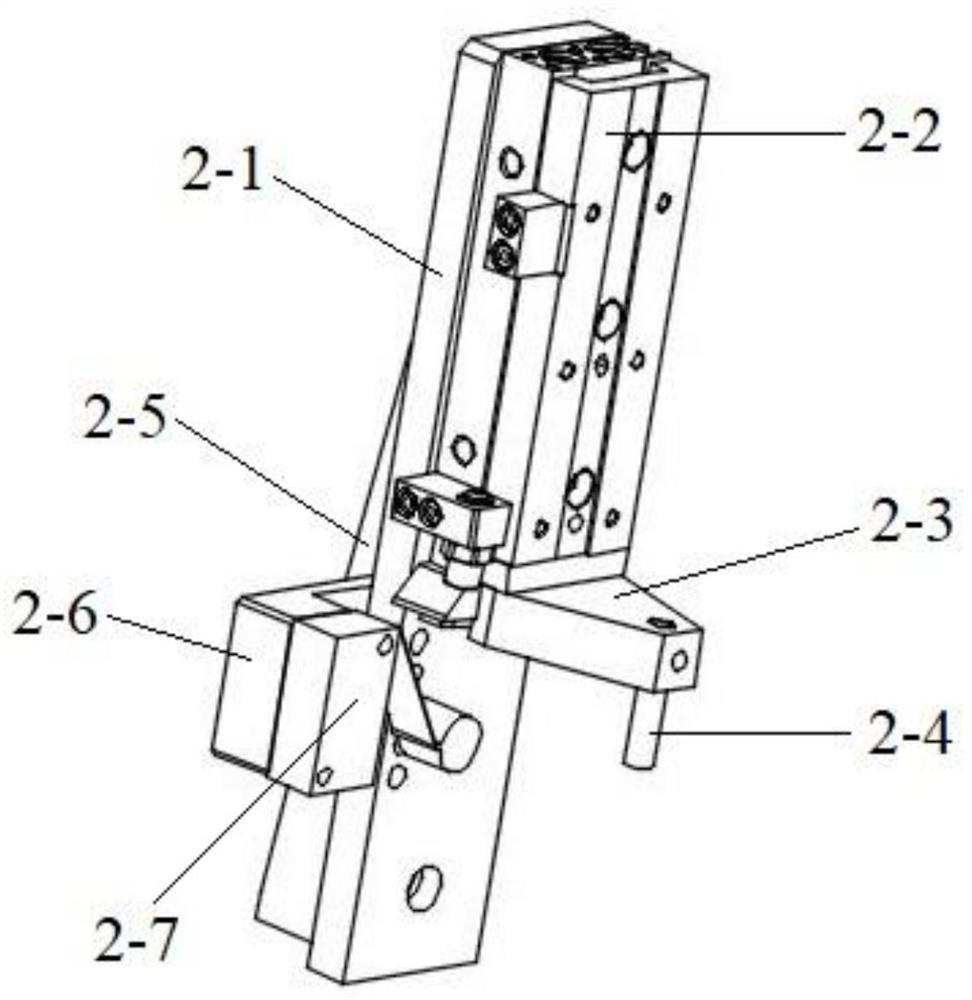

[0037]A pressing mechanism 2 is used to press the semi-finished probes to ensure reliable placement and to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com