Vegetable liquid spray pollination spray head with adjustable spray width

A spray pollination, adjustable technology, applied in the direction of plant genetic improvement, botanical equipment and methods, application, etc., can solve the problems of inability to adapt to pollination work, insufficient pollination, low work efficiency, etc., to increase the amount of pollen deposition, avoid Pollen grain waste, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

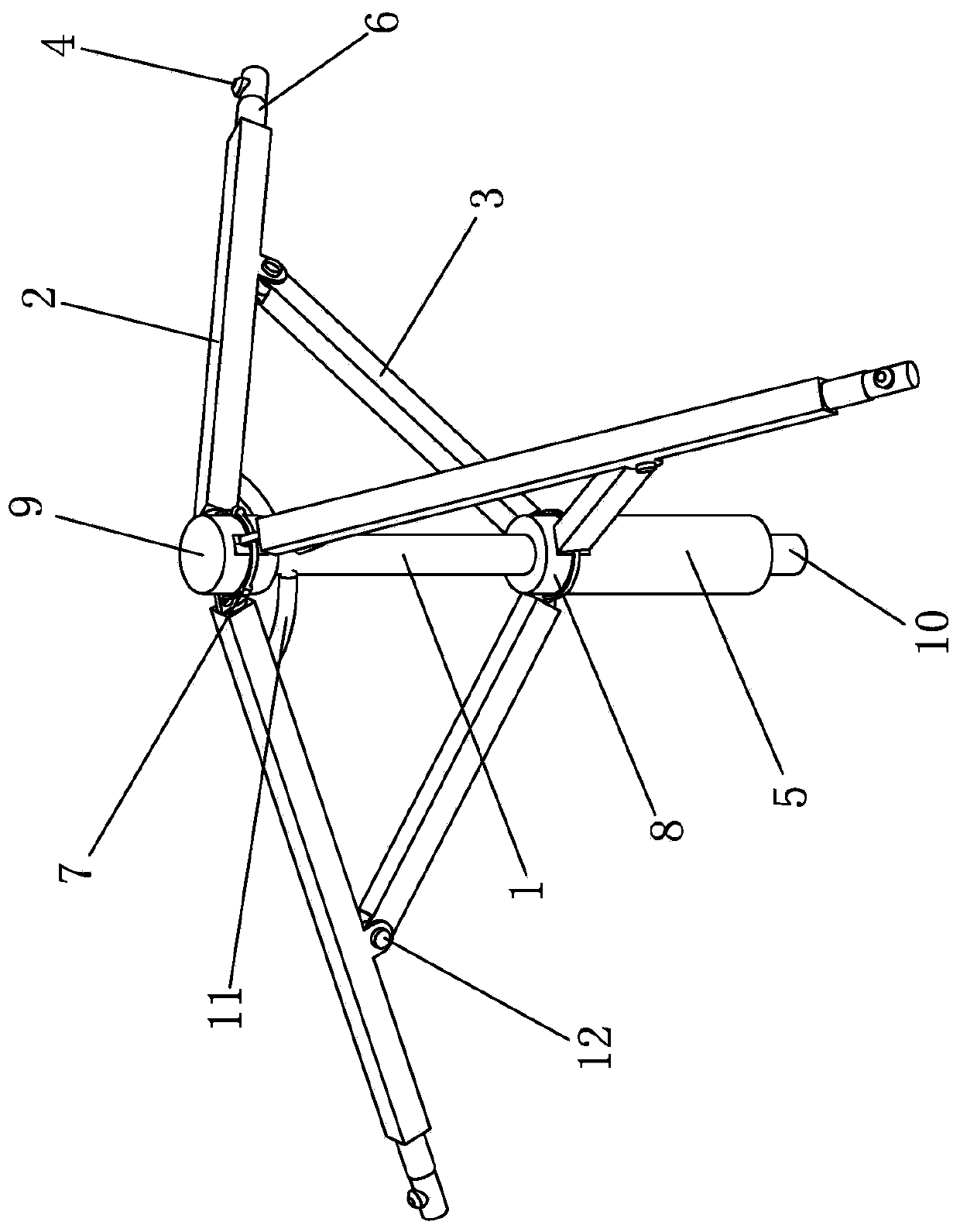

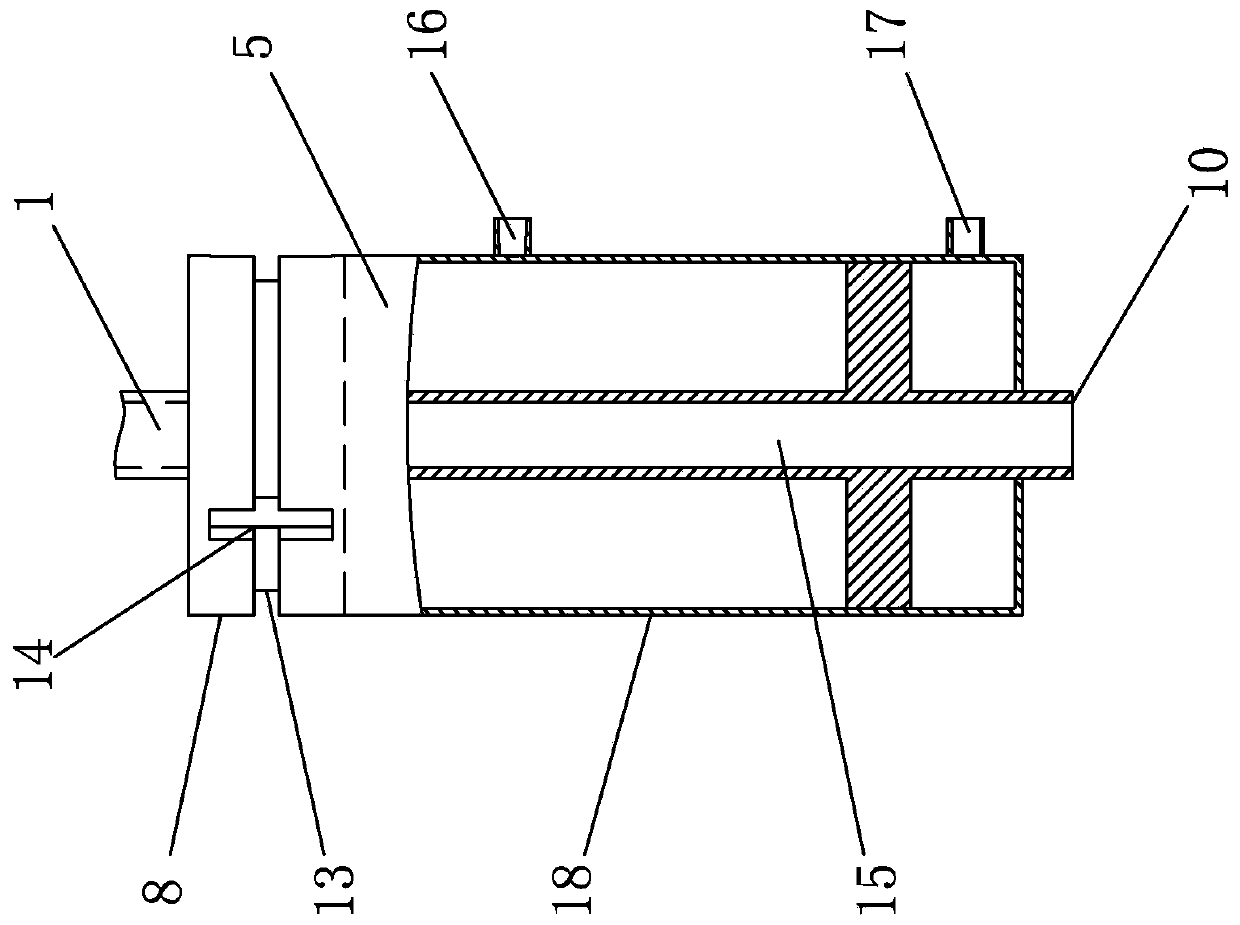

[0017] like Figure 1-2 As shown, a vegetable liquid spray pollination nozzle with adjustable spray width includes a pollination robot arm; the spray pollination nozzle is composed of a central axis 1, a telescopic arm 2, a support rod 3, a nozzle 4, a hydraulic cylinder 5, and a telescopic joint. 6. Ring pin 7, sliding connection column 8, fixed connection column 9, telescopic hose 11, pin 12, and pipeline 15 are connected; the position adjustment axis 1 is fixed at the end of the pollination robot mechanical arm, and the position adjustment axis 1 The top of the shaft is provided with a fixed connecting column 9, and the shaft body of the positioning axis 1 is provided with a sliding connecting column 8, and the columns of the sliding connecting column 8 and the fixed connecting column 9 are provided with an annular groove 13 and a plurality of vertical grooves 14, A tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com