Preparation method of graphene loaded palladium nanoparticle composite material catalyst

A technology of palladium nanoparticles and composite materials, which is applied in the field of preparation of graphene-supported palladium nanoparticle composite catalysts, can solve the problems of complex process, poor repeatability, high cost, etc., and achieve the effect of simple process flow, easy implementation and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

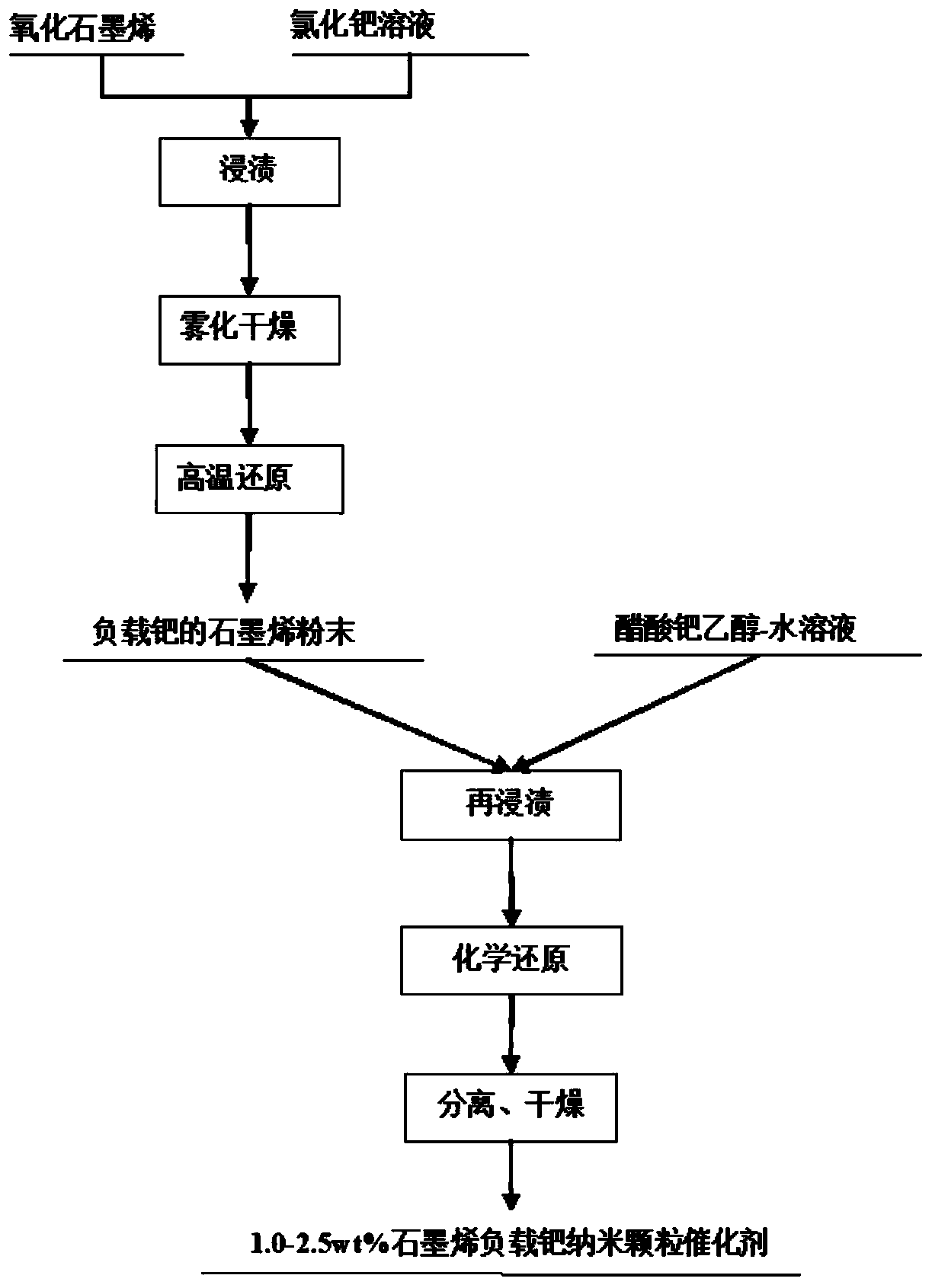

[0019] (1) Impregnation process: pipette an appropriate volume of a certain concentration of palladium chloride solution, then take an appropriate amount of graphene oxide aqueous solution according to the mass ratio of the carrier to palladium of 400:1, put it into the solution, and immerse for 36 hours.

[0020] (2) Spray drying process: use a spray dryer to control the liquid flow rate of 4.0ml / min for the mixed solution obtained in (1), the atomization pressure is 0.4MPa, the inlet temperature is 180°C, and the hot air flow rate is 8.0L / min. min, carry out drying treatment, and receive the graphene oxide powder containing palladium.

[0021] (3) High-temperature reduction process: the palladium-containing graphene oxide powder obtained in (2) was reduced in a tube furnace in a hydrogen atmosphere at 500° C. for 1 hour, and the palladium-loaded graphene powder was obtained.

[0022] (4) Re-impregnation process: Weigh an appropriate amount of palladium acetate, dissolve it w...

Embodiment 2

[0026] Palladium nanoparticle-graphene catalyst of the present invention is made by following process:

[0027] (1) Impregnation process: pipette an appropriate volume of palladium chloride solution with a concentration of , and then take an appropriate amount of graphene oxide aqueous solution according to the mass ratio of the carrier to palladium as 1000:1, and put it into the solution, and immerse for 24 hours .

[0028] (2) Spray drying process: use a spray dryer to control the liquid flow rate of 6.0ml / min for the mixed solution obtained in (1), the atomization pressure is 0.3MPa, the inlet temperature is 180°C, and the hot air flow rate is 8.0L / min. min, carry out drying treatment, and receive the graphene oxide powder containing palladium.

[0029] (3) High-temperature reduction process: the palladium-containing graphene oxide powder obtained in (2) was reduced in a tube furnace in a hydrogen atmosphere at 500° C. for 1 hour to obtain palladium-loaded graphene powder....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap