Powder high-precision weighing device and method thereof

A weighing device and high-precision technology, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of prolonging the feeding time, difficulty in controlling powder materials, and difficulty in controlling, so as to reduce excessive cutting, Avoid excessive cutting, which is beneficial to the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

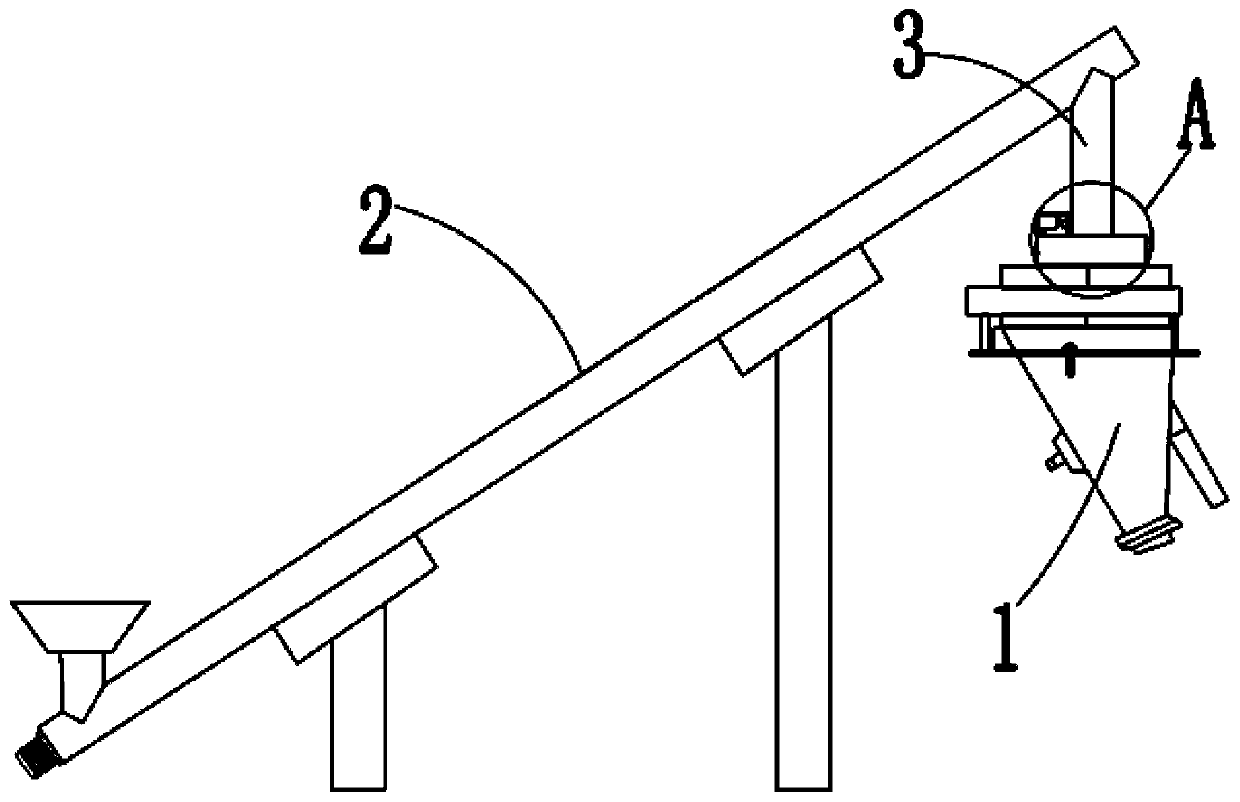

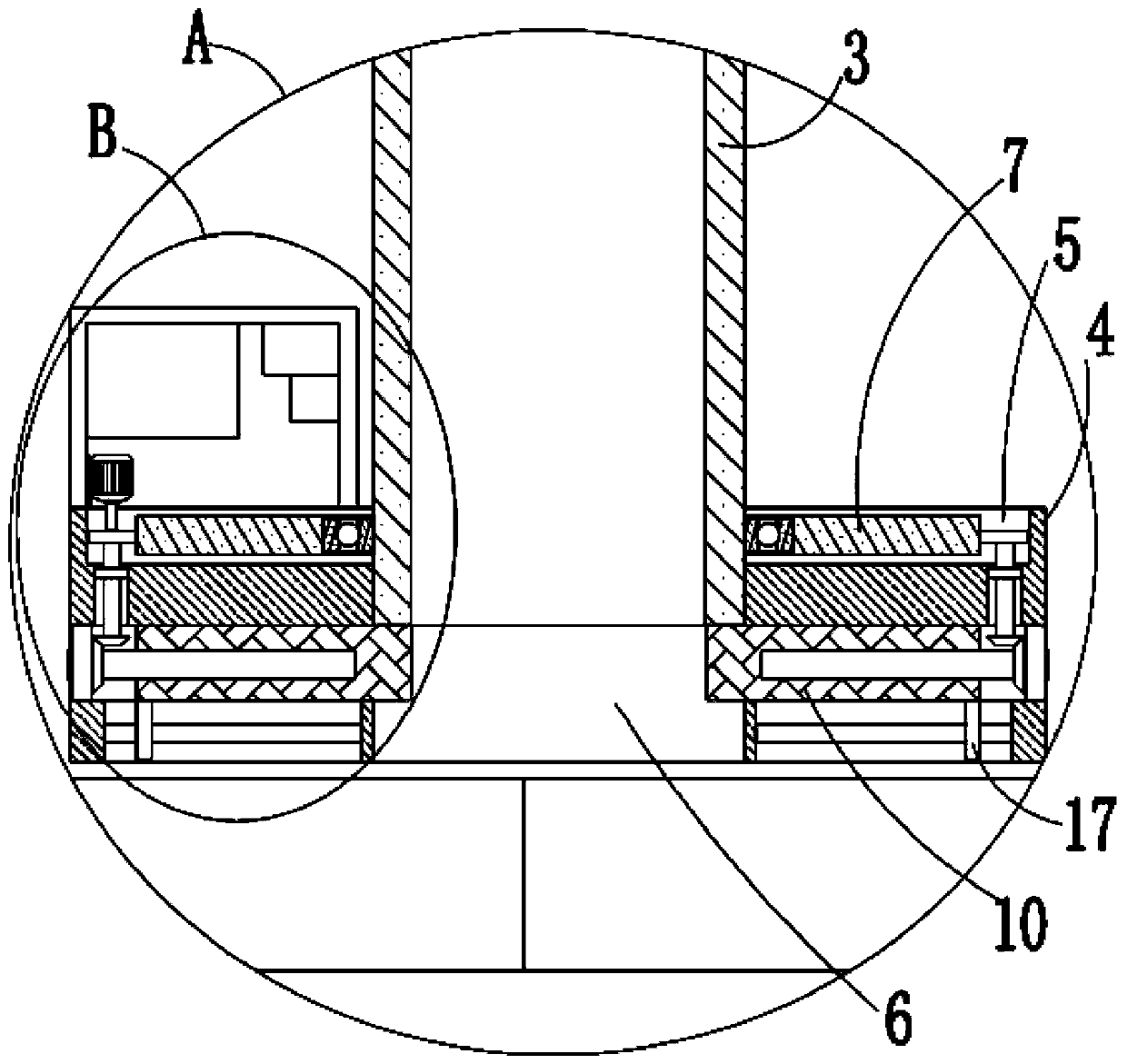

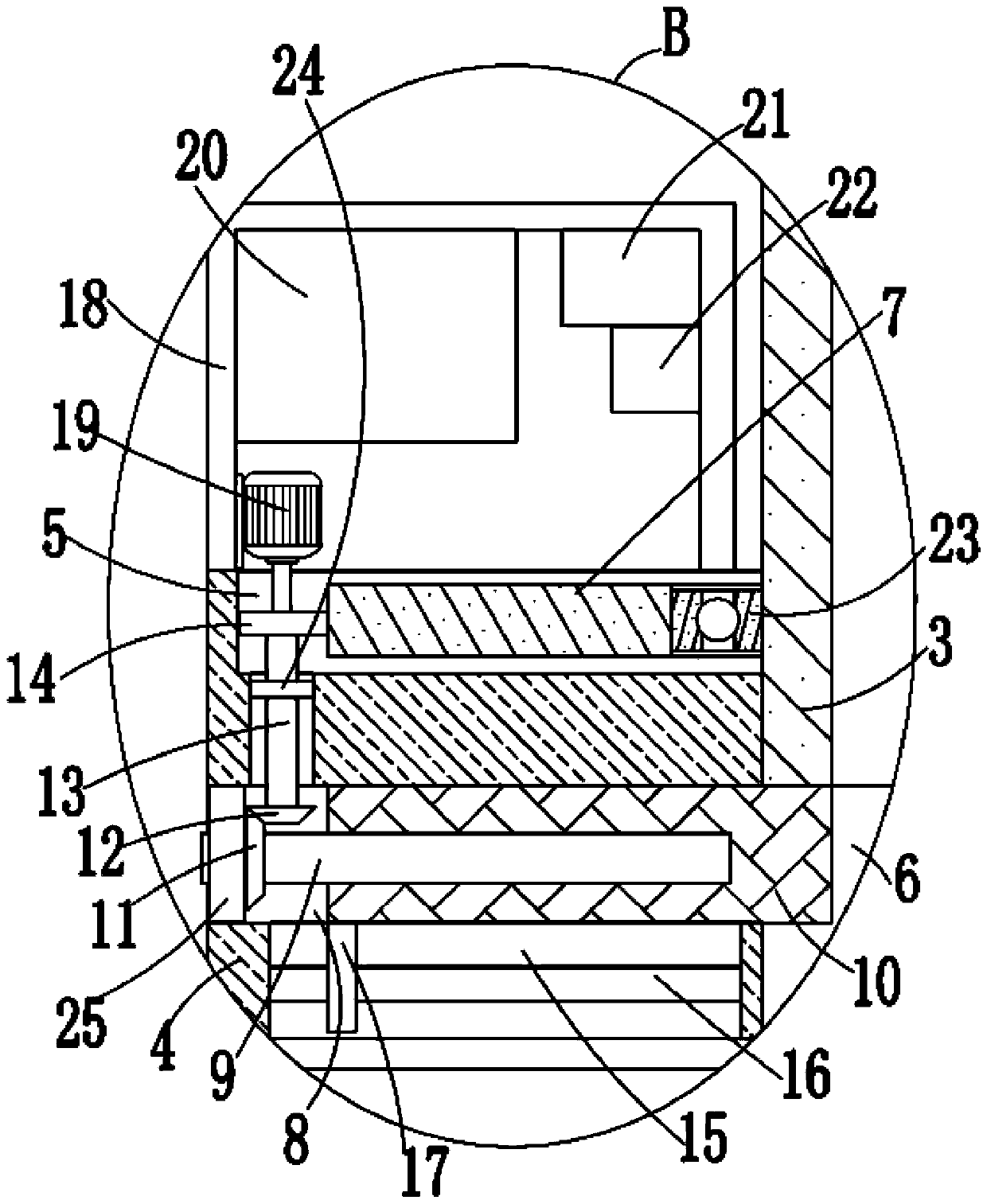

[0031] refer to Figure 1-5 , this embodiment proposes a high-precision powder weighing device, including a powder weighing hopper 1 and an inclined screw conveyor 2 located on one side of the powder weighing hopper 1, the bottom side of the screw conveyor 2 is connected and A discharge pipe 3 is fixed, the discharge pipe 3 is located above the powder metering hopper 1, a rectangular seat 4 is arranged above the powder metering hopper 1, and a circular groove 5 is opened on the top of the rectangular seat 4, and the circular groove 5 There is a blanking square hole 6 on the bottom inner wall of the bottom, and the bottom end of the discharge pipe 3 runs through the circular groove 5 and extends into the blanking square hole 6. The bottom of the four sides is welded and fixed, and the discharge pipe 3 is rotated to be provided with a large gear 7 located in the circular groove 5. The inner walls of both sides of the blanking square hole 6 are provided with a first rectangular h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com