Anhydrous stemming for blast furnace tap hole

A blast furnace tapping and anhydrous taphole technology, applied in the field of refractory materials, can solve the problem of high cost of raw materials, and achieve the effects of long tapping time, easy mudding, and protection of the tap hole area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in more detail below through specific embodiments, so as to facilitate the understanding of those skilled in the art.

[0035] Recycled refractory materials used in the present invention, including torpedo tank lining bricks, iron gutter castables, silicon carbide plates, silicon carbide carbon bricks, slide plates, and silicon molybdenum bricks, are all used refractory materials in this industry as solid waste, and they need to be used first. Composition testing can be used only after meeting the component requirements; raw materials pyrophyllite, ferrosilicon nitride, high-temperature asphalt powder, clay powder, and coal tar and anthracene oil for preparing mixed oil binders are all commercially available products.

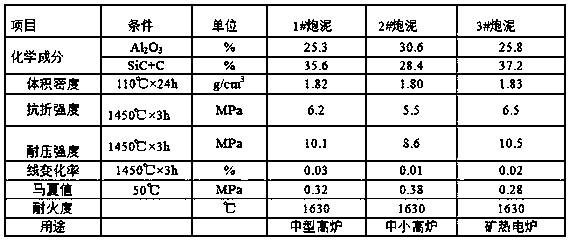

[0036] The present invention enumerates three preparation examples according to following table 1:

[0037] Table 1

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com