General gasoline engine with new silencer

A general-purpose gasoline engine and muffler technology, applied in the field of gasoline engines, can solve the problems of shortened service life, inconvenient cleaning, and high noise of muffler equipment, and achieve the effects of prolonging service life, convenient cleaning, and reducing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

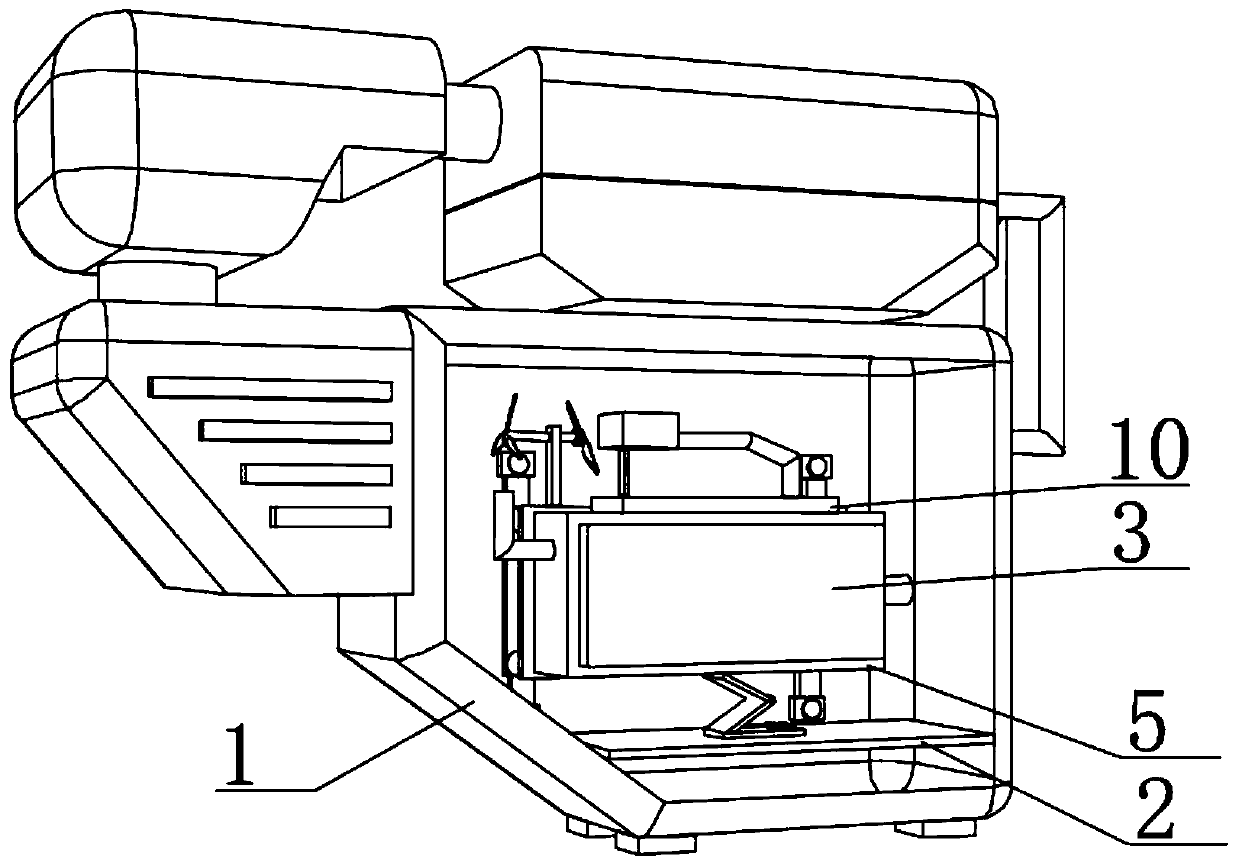

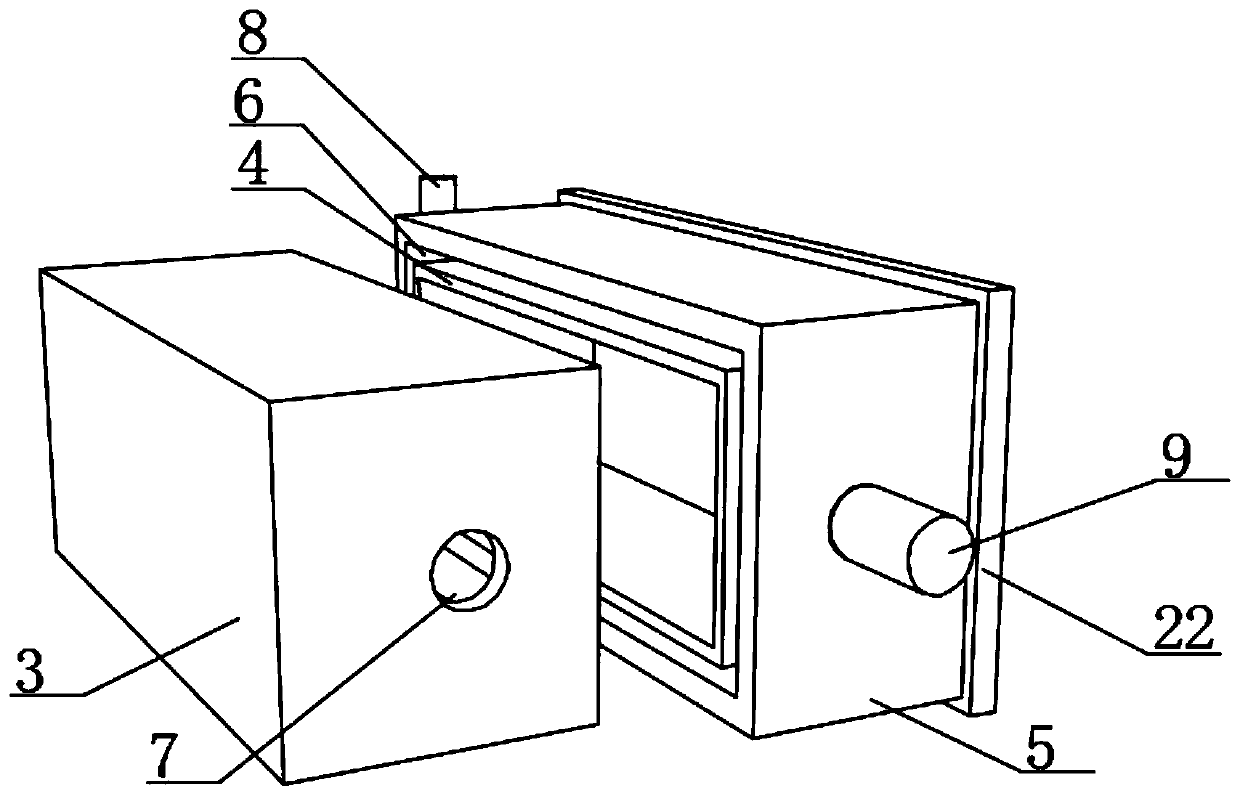

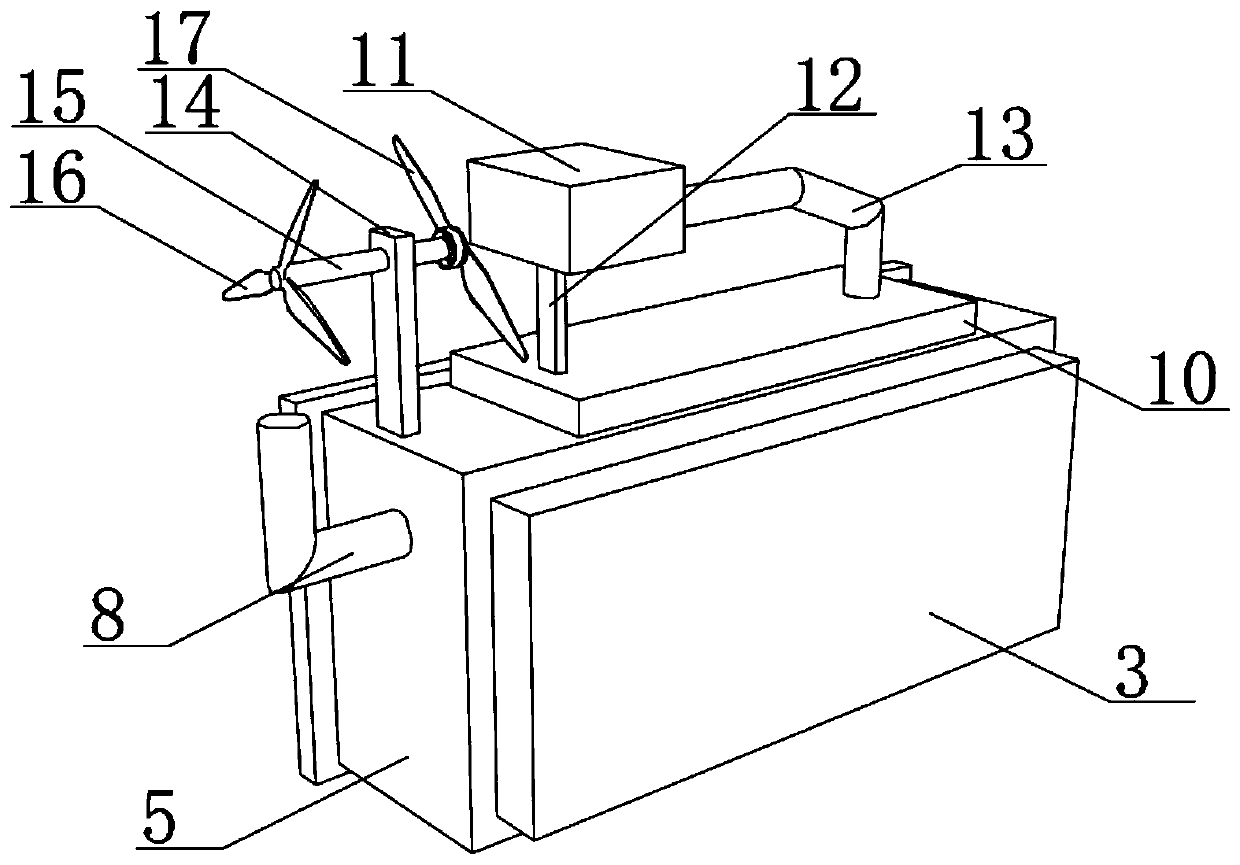

[0019] see Figure 1~4 , in the embodiment of the present invention, a general-purpose gasoline engine with a novel muffler includes a casing 1 and a support plate 2, the support plate 2 is arranged at the bottom of the casing 1, and the upper side of the support plate 2 is respectively provided with an inner cover 4 and a The outer cover 5 and the inner cover 4 are arranged on the inner side of the outer cover 5, and one end of the inner cover 4 and the outer cover 5 is fixedly provided with a first plate 22, and the other end of the inner cover 4 and the outer cover 5 is provided with a sliding cover 3, and the outer cover 5 The upper end of the upper end is provided with a liquid storage tank 10 and a condensation tank 11, and a Z-shaped damping plate 18 is connected between the upper end of the support plate 2 and the lower end of the outer cover 5, and the inside of the inner cover 4 and the outer cover 5 forms a card slot 6, The sliding cover 3 is fitted inside the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com