Unmanned rolling machine group path planning method

A path planning and rolling machine technology, which is applied to road network navigators, measuring devices, instruments, etc., can solve problems such as low equipment utilization, collision with obstacles, and unbalanced task division, so as to meet the construction quality and improve construction The effect of low schedule and time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

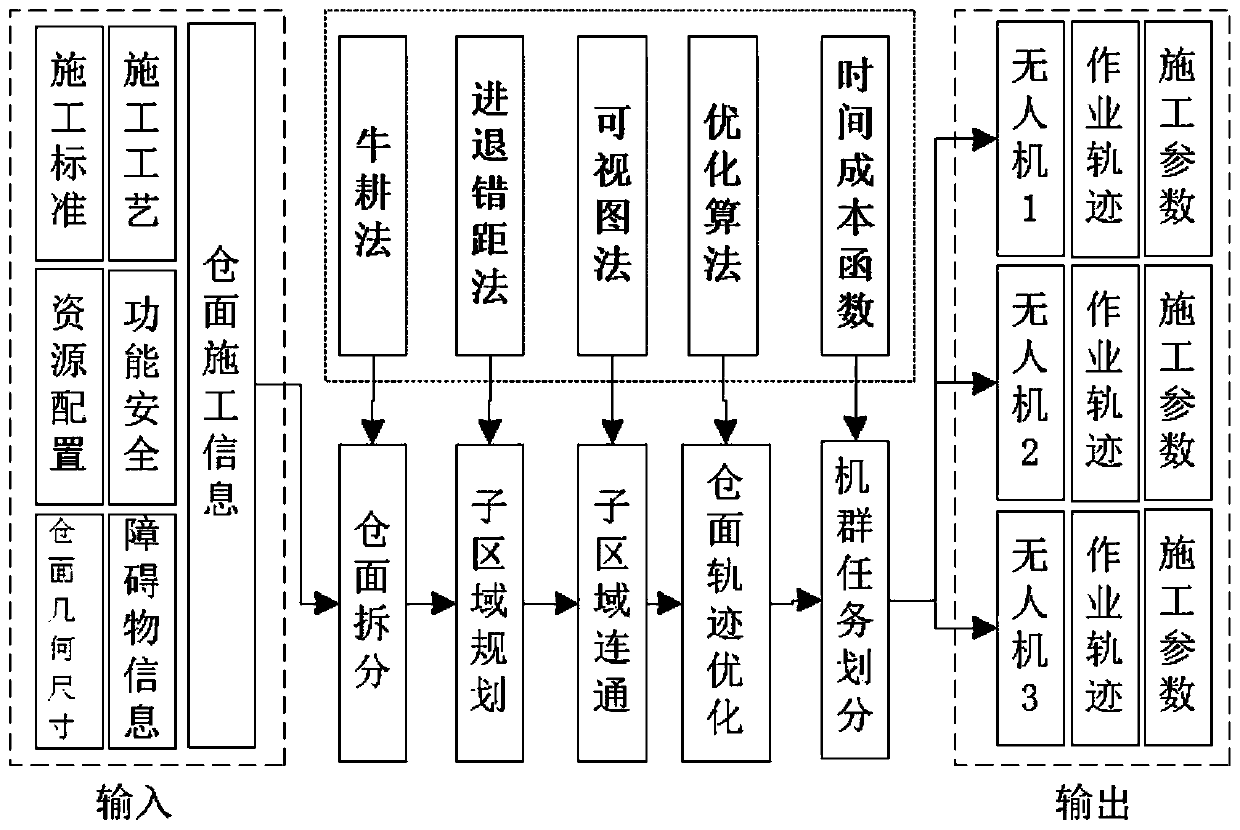

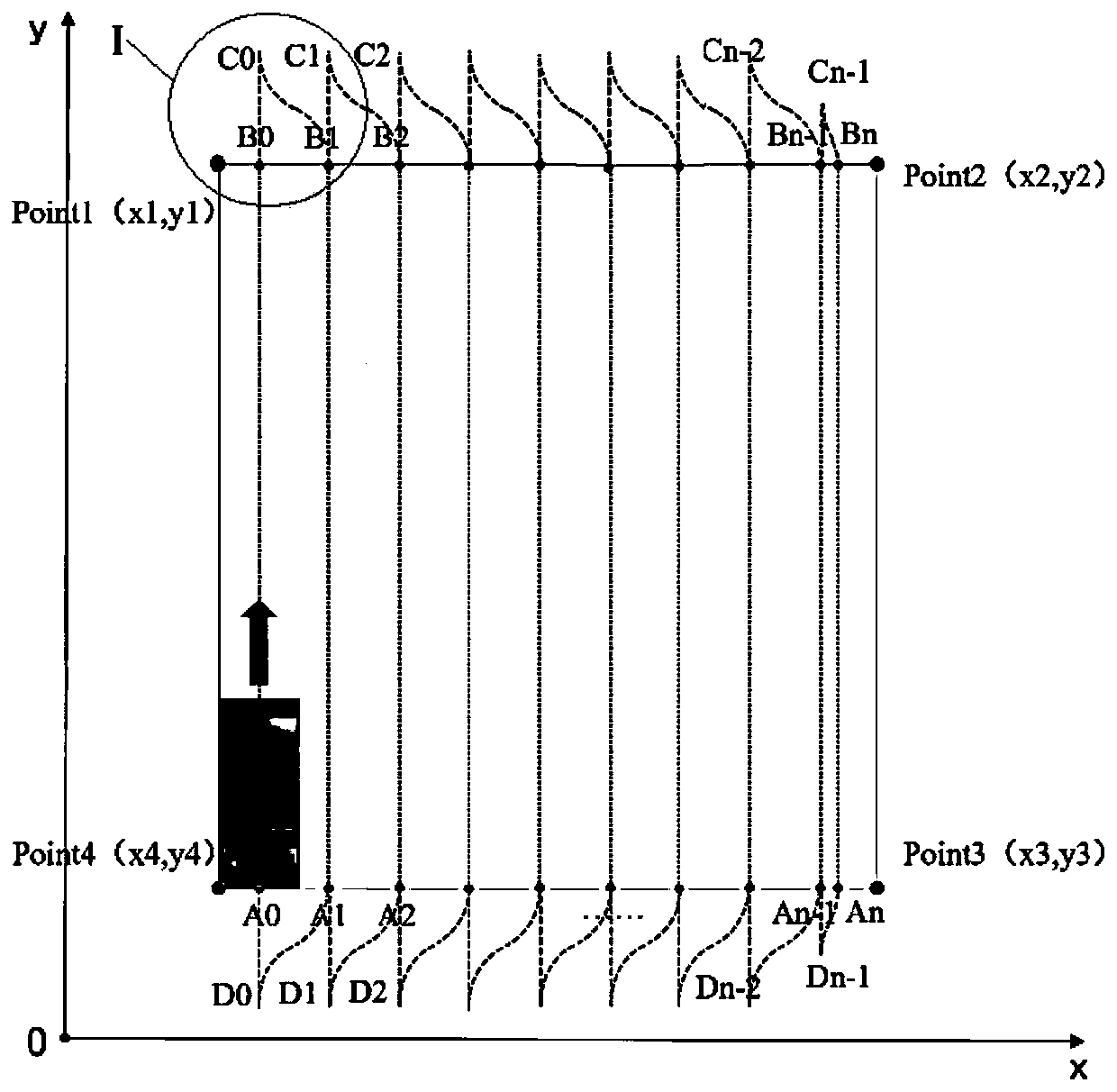

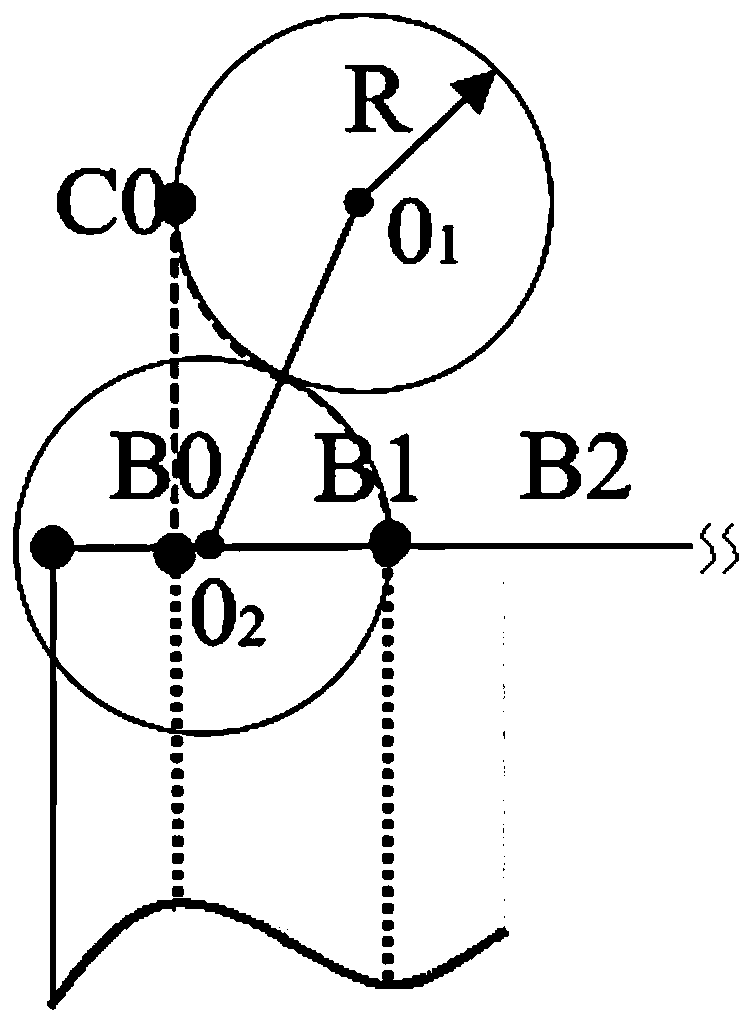

[0030] See Figure 1 to Figure 3 , a path planning method for an unmanned rolling mill group, which includes the following steps in turn: splitting the warehouse surface, planning the operation path within the sub-bin surface, planning the transition operation path between the sub-bin surfaces, and splitting the operation path of the machine group; Plane splitting is to split the total operating compartment surface into several sub-compartment surfaces; the operation path planning within the sub-compartment plane is to plan the rolling operation path of the rolling machine in the sub-compartment plane; the transition operation path between sub-compartment surfaces Planning is to plan the transition operation path of rolling mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com