Automobile wind resistance coefficient optimization method based on self-adaptive agent model

An adaptive proxy, wind resistance coefficient technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve the problems of low optimization efficiency, complicated operation, long time consumption, etc., to reduce research and development costs, engineering experience requirements Low, reduce the effect of the number of calls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

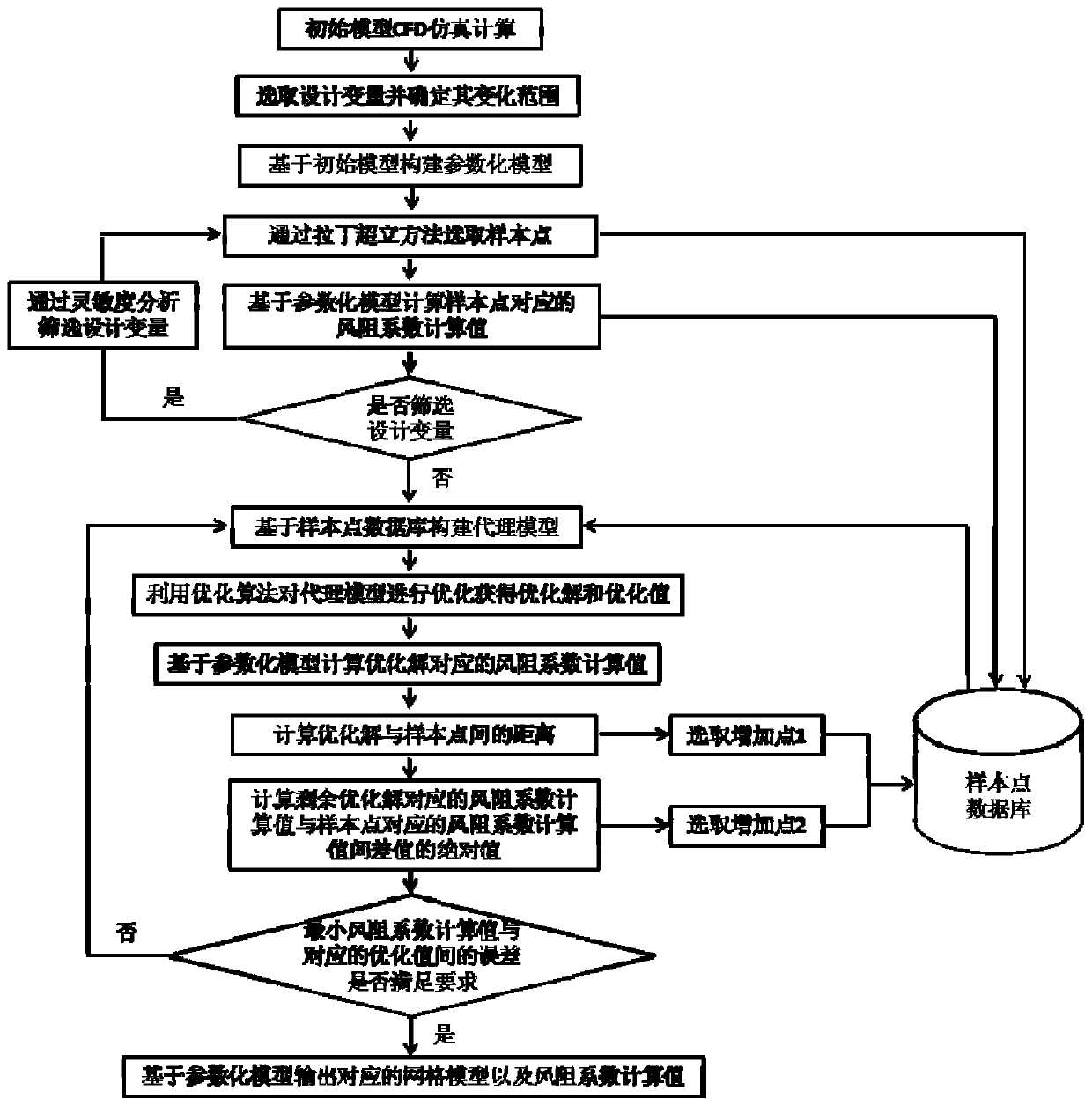

[0035] Such as figure 1 As shown, the vehicle drag coefficient optimization method based on the adaptive proxy model includes the following steps:

[0036] A. Carry out CFD simulation calculation on the initial model of the car to obtain the calculated value of the drag coefficient of the initial model;

[0037] B. Select the design variables and determine the variation range of the design variables;

[0038] C. Construct a parametric model based on the initial model;

[0039] D. Select a sample point and store it in the sample point database;

[0040] E. Calculate the drag coefficient calculation value corresponding to the sample point based on the parameterized model, and store it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com