Method for producing wide-angle camera module by using non-wide-angle machine

A wide-angle camera and wide-angle machine technology, which is applied in the field of wide-angle machine production of wide-angle camera modules, can solve the problem that the quality of the finished product of the wide-angle camera module needs to be further improved, and achieve the effect of improving the quality of the finished product and a reasonable detection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

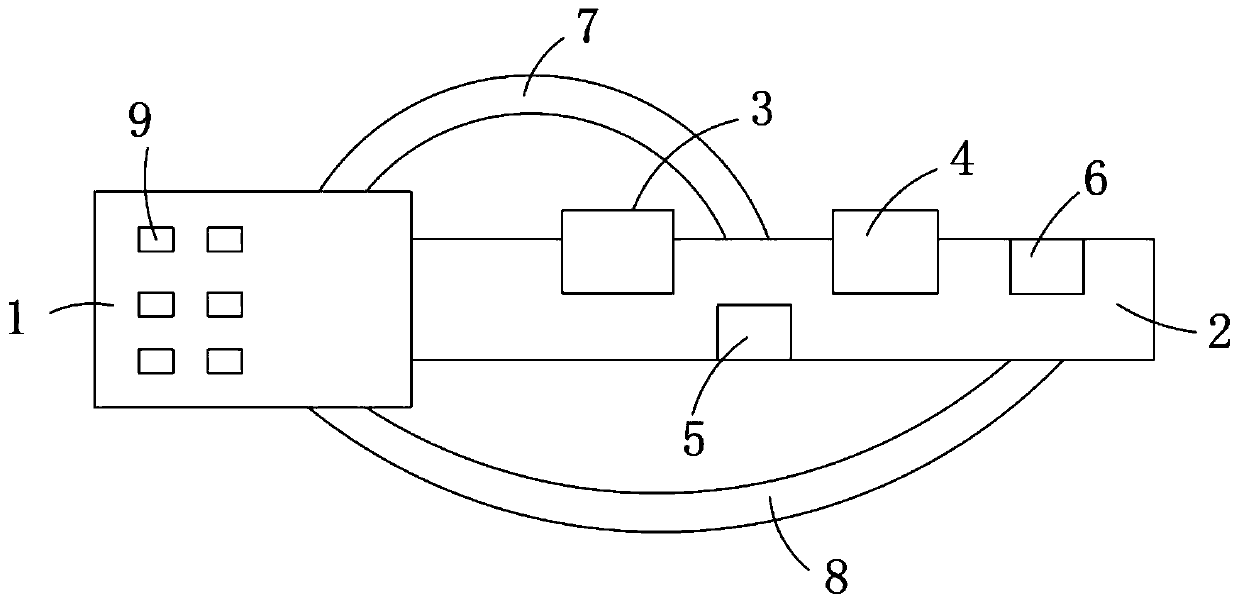

[0033] Such as Figure 1-3 As shown, the embodiment of the present invention provides a method for producing a wide-angle camera module with a non-wide-angle machine, and the method includes the following steps:

[0034] S1. In the wide-angle camera module production area 1, use several non-wide-angle machine equipment 9 to process raw materials to produce a wide-angle camera module, and place the finished wide-angle camera module in the main transmission unit 2 for transmission;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com