High-density textile physical property detection method

A detection method and textile technology, applied in the direction of strength characteristics, measuring devices, using stable tension/pressure to test the strength of materials, etc., can solve problems such as poor batches, unacceptable, inconsistent temperatures between left and right dyeing vats, and achieve industrial value promotion Improvement, improve product quality, strengthen the effect of monitoring and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

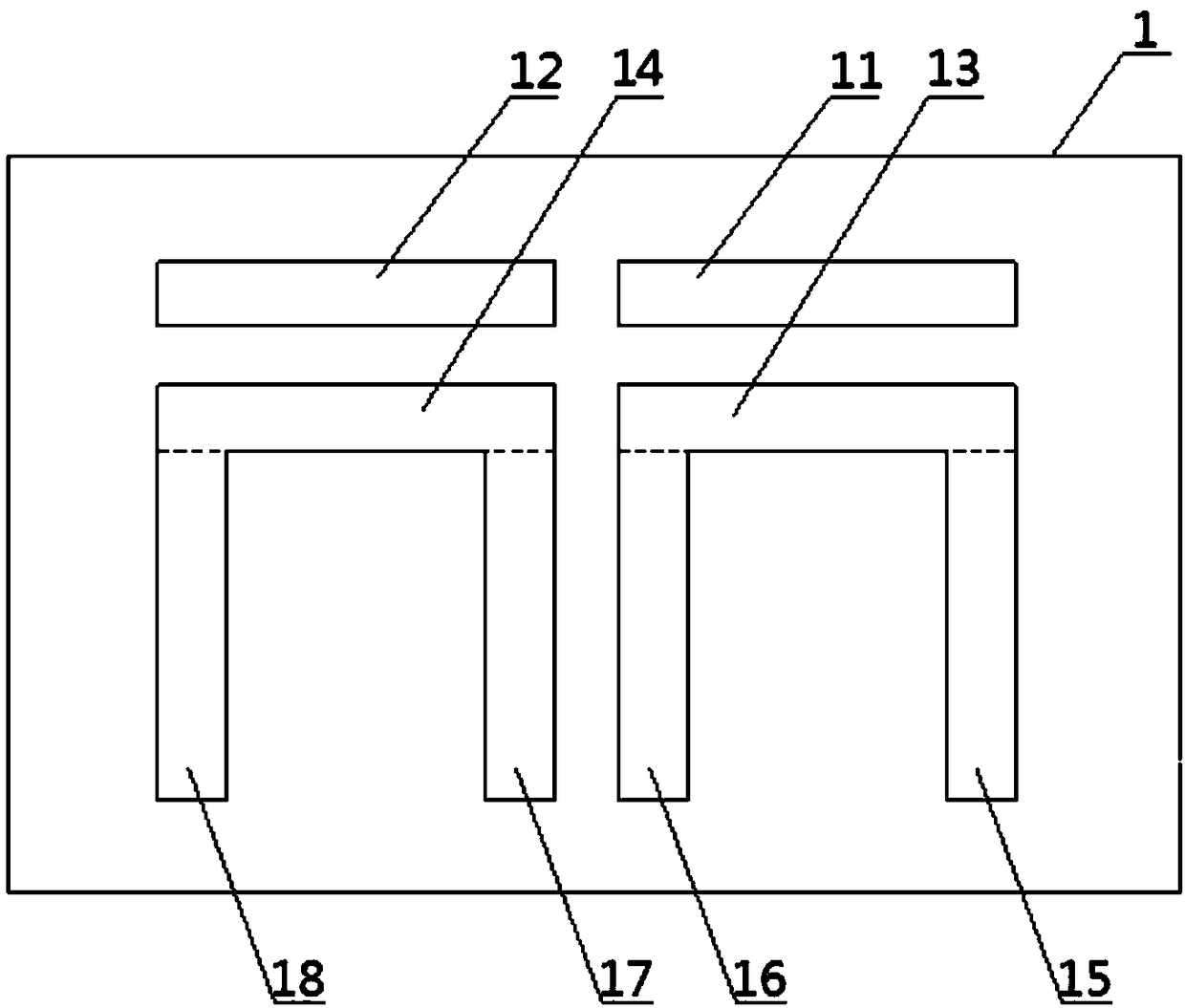

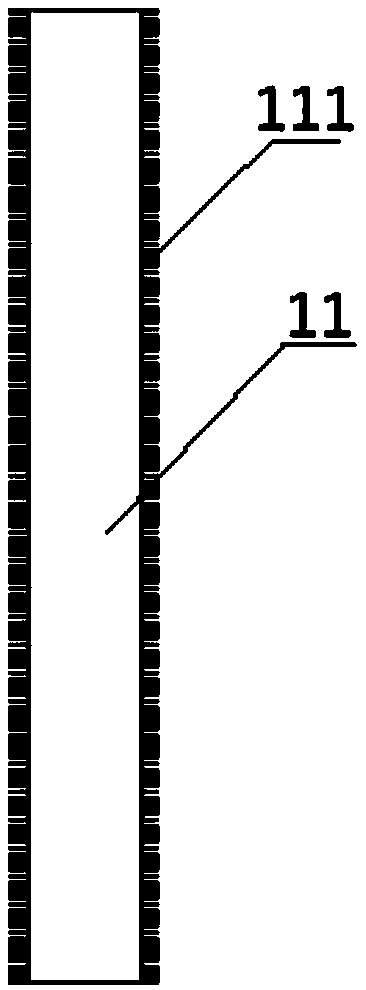

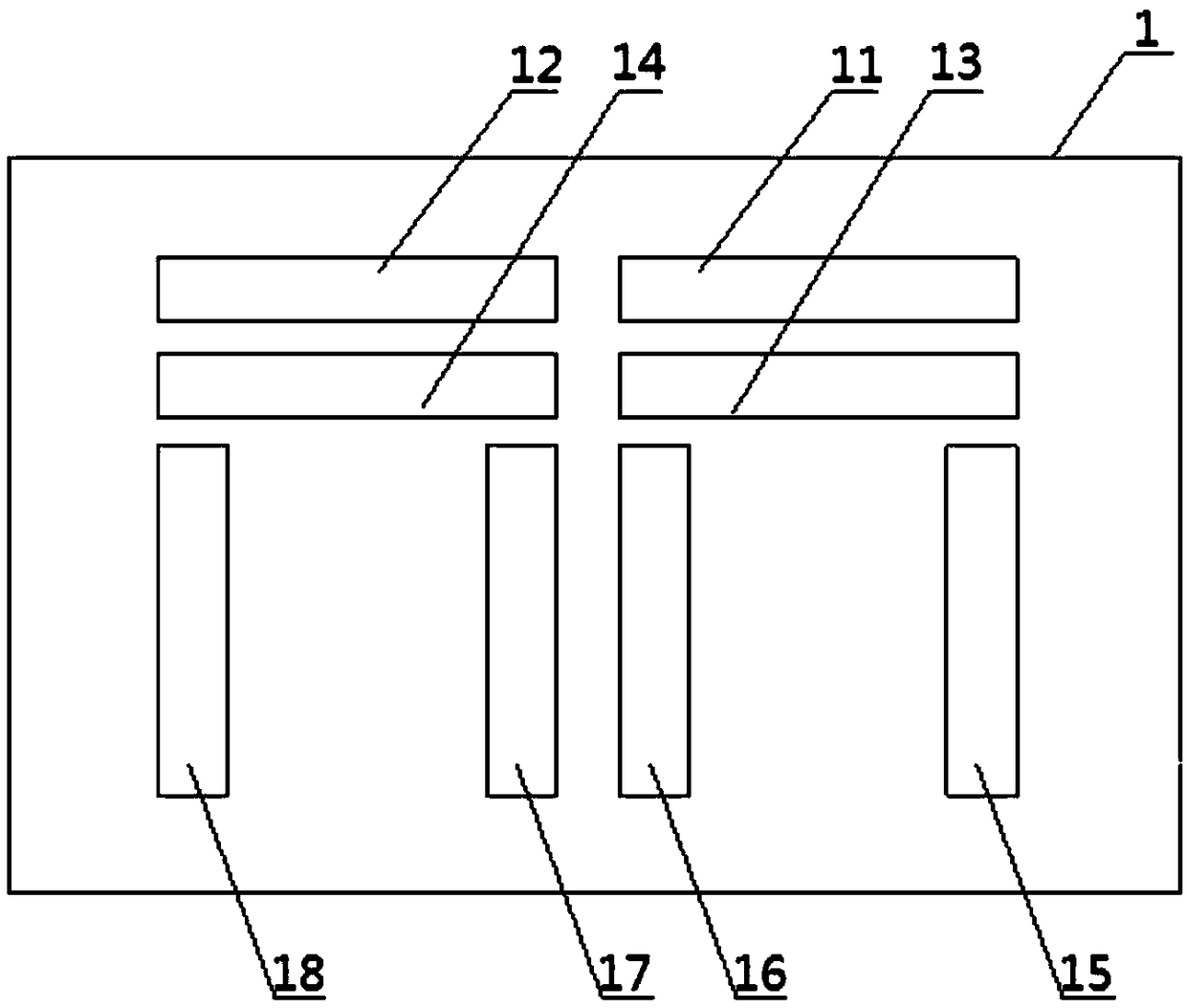

[0043] Such as Figure 1-4 As shown, in the textile physical property detection method described in the embodiment of the present invention, the purpose of implementing the technical means is to solve the problem that the quality of textile products cannot be further improved due to the difficulty in implementing effective, reliable, and simple physical property detection techniques for textiles. The reason why there is still no reasonable means to solve this technical problem is that in the past, when testing the physical properties of textile products, the quality of textiles was generally determined primarily through the quality inspector's intuitive quality performance of the fabric or the observation of local details. , the completion of the whole process is manual detection without reference to a more systematic detection method. Therefore, neither the obtained intuitive quality performance nor the local details with excellent quality performance are sufficient to charact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com