Prebaked anode roasting furnace flue gas purification device

A flue gas purification and pre-baked anode technology, which is applied in the direction of combined devices, transportation and packaging, chemical instruments and methods, etc., can solve the problems of filter blockage, time-consuming and labor-consuming, poor cleaning effect, etc., and achieve high purification efficiency, Good flue gas purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

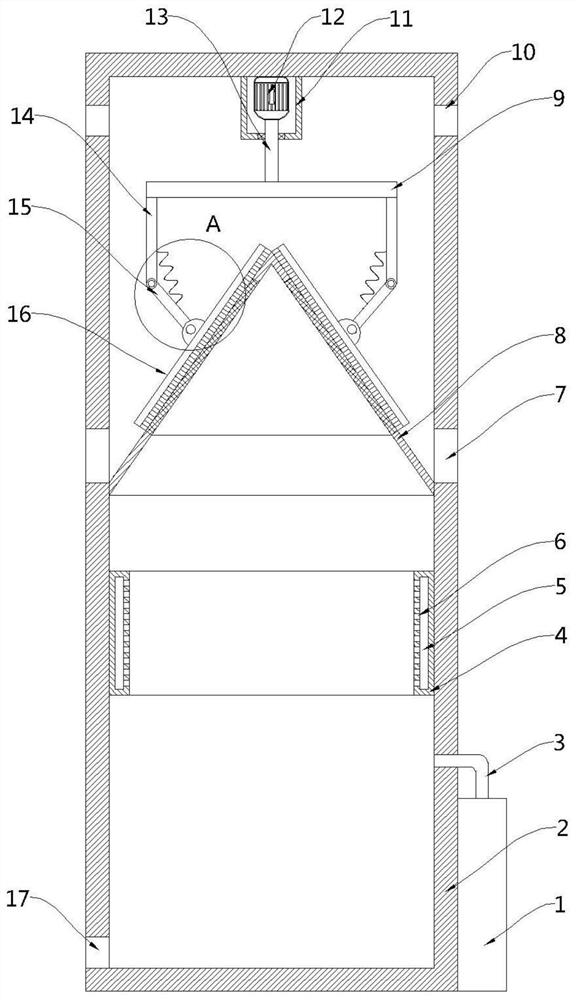

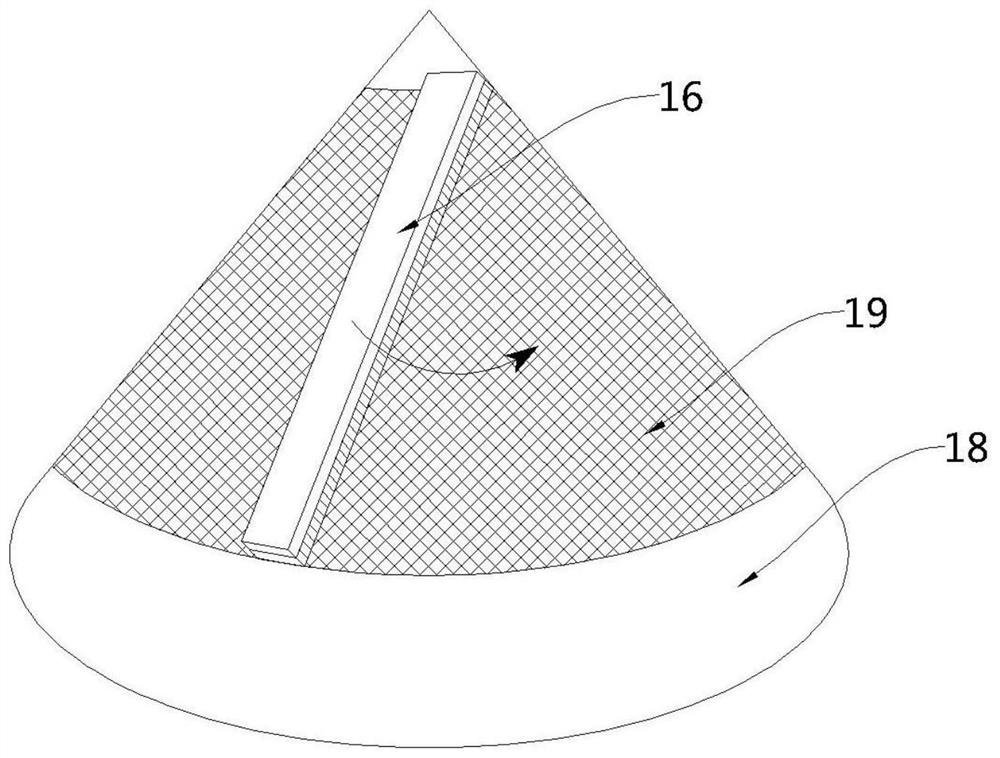

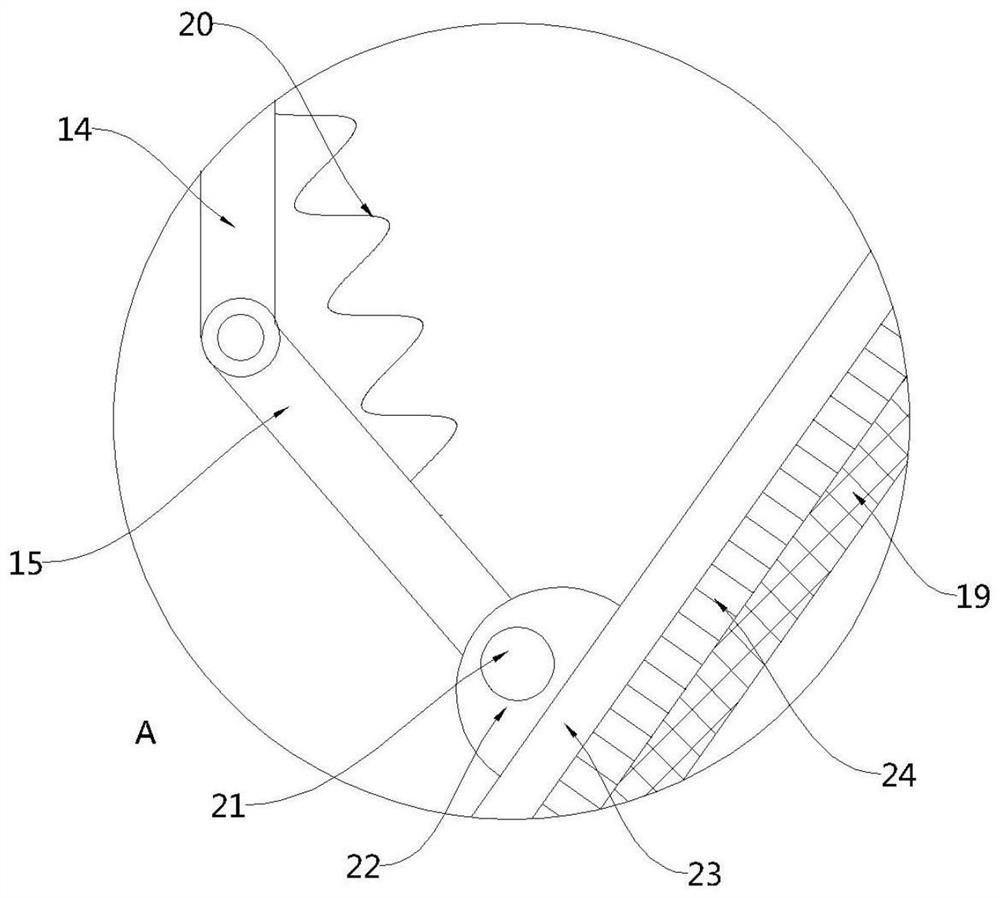

[0025] see Figure 1-3 , this embodiment provides a flue gas purification device for a prebaked anode roaster, which includes a purification box 2 and a fan 1 arranged at the bottom of the outer side of the purification box 2, and the output end of the fan 1 communicates with the air duct 3 through an air duct 3. The purification box 2 is connected, the upper part of the side wall of the purification box 2 is provided with an air inlet 10, the inside of the purification box 2 is located below the air inlet 10, and a smoke filter assembly 8 is arranged, and the smoke filter assembly 8, a cleaning assembly 16 is attached to the upper part, and the top of the purification box 2 is provided with a driving assembly for driving the cleaning assembly 16 to scrape along the upper part of the smoke filter assembly 8. Specifically, the smoke filter The assembly 8 includes a tapered support plate 18 fixedly installed on the inner wall of the purification box 2 and a filter screen 19 embe...

Embodiment 2

[0040] see figure 1 , a flue gas purification device for a prebaked anode roaster. Compared with Embodiment 1, this embodiment is further provided with a spray ring plate distributed along the inner circumference of the purification box 2 under the conical support plate 18 4. The inside of the spray ring plate 4 is provided with a water inlet channel 5, and the inner wall of the spray ring plate 4 is provided with a number of spray holes 6 communicating with the water inlet channel 5, and the outside of the purification box 2 is also provided with There is a water tank (not shown) connected to the spray ring plate 4 pump.

[0041] The water in the external water tank is pumped into the water inlet channel 5 inside the spray ring plate 4, and then sprayed out from a number of spray holes 6 on the inner wall of the spray ring plate 4 to spray a small amount of dust particles in the downstream flue gas Settling, so as to achieve further purification of flue gas dust.

[0042] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com