A kind of polyethylene material processing equipment

A technology of material processing and polyethylene, which is applied in the field of polyethylene material processing equipment, can solve problems such as rebound jumping and collision, and achieve the effect of avoiding rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

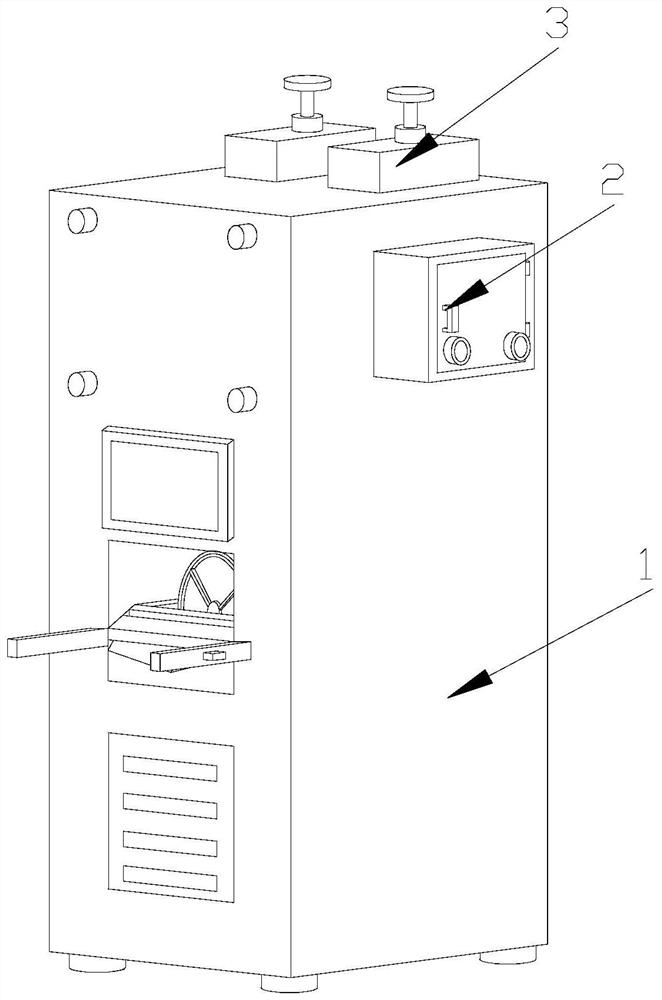

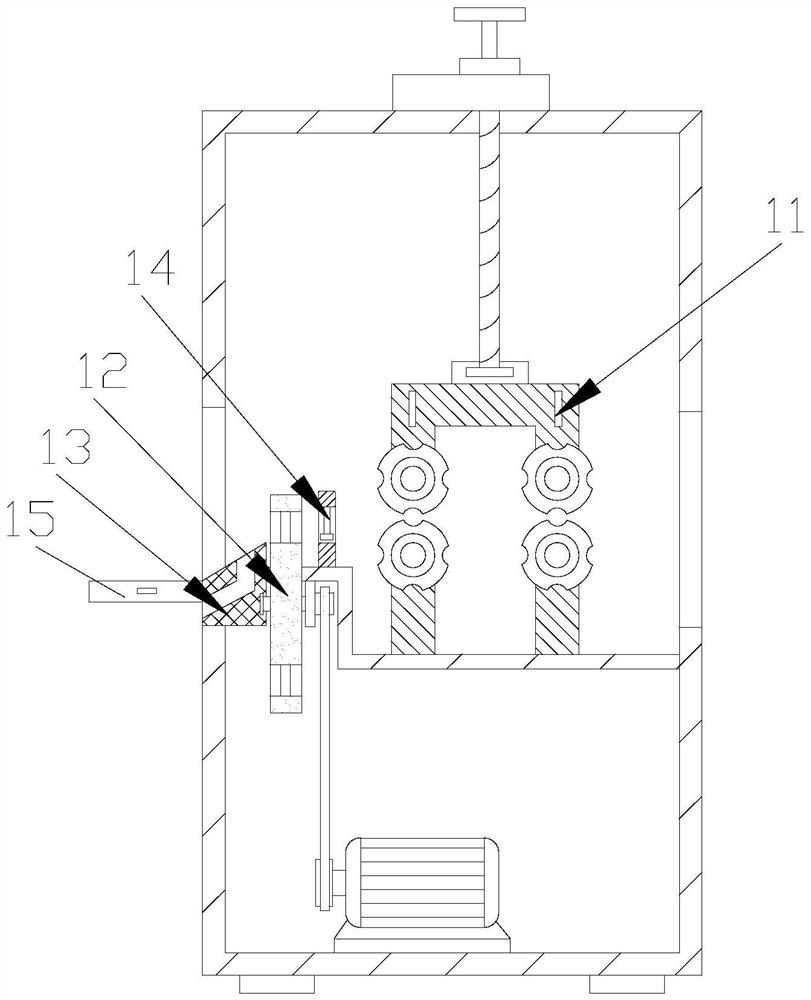

[0026] Example 1: Please refer to Figure 1-Figure 5 The specific embodiment of the present invention is as follows: its structure includes a main body 1, a control box 2, and an adjustment block 3. The side end of the main body 1 is embedded with the control box 2, and the adjustment block 3 is embedded on the top of the main body 1. The main body 1 includes a guide roller 11, a cutting block 12, a guide block 13, a pressing block 14, and a hook 15. The guide roller 11 is arranged in the middle of the main body 1, the cutting block 12 is located at the front end of the main body 1, and the guide The block 13 is embedded in the front end of the cutting block 12 , the pressing block 14 is located in the rear end of the cutting block 12 , and the hook 15 is embedded in the front end of the guide block 13 .

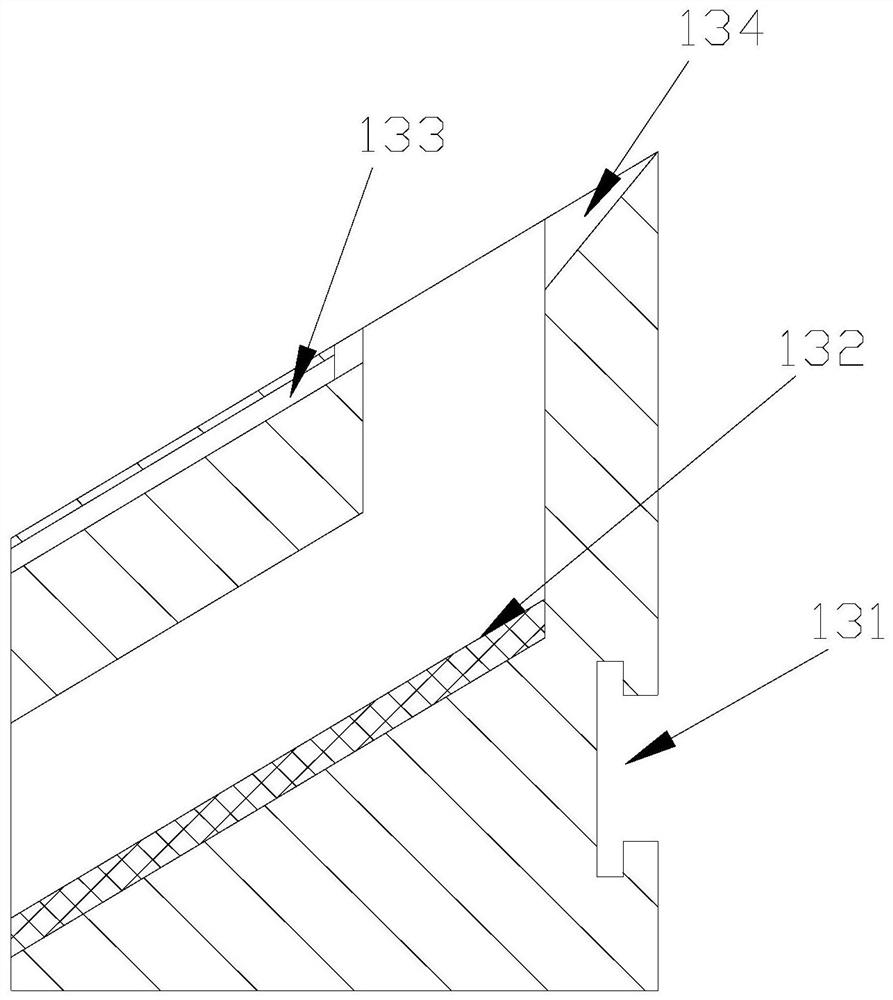

[0027] The guide block 13 includes an engaging groove 131, a feeding groove 132, a material guiding groove 133, and a dropping groove 134. The engaging groove 131 is arrange...

Embodiment 2

[0031] Example 2: Please refer to Figure 6-Figure 8 The specific embodiment of the present invention is as follows: the pressing block 14 includes a pressing groove 141, a telescopic rod 142, and a pressing body 143. At the top, the angle between the bottom of the pressing groove 141 and the horizontal plane is 30 degrees, which is beneficial for the pressing body 143 to press the strip-shaped polyethylene material, so that the strip-shaped polyethylene material bends downward, allowing the cutting block 12 to cut into Polyethylene pellets can fall straight down.

[0032] The pressing body 143 includes a support block b1, a slot b2, and a roller b3. The bottom of the support block b1 is provided with four slots b2, the slot b2 is circular, and the roller b3 is provided with four, And engaged in the slot b2, the bottom of the support block b1 is arc-shaped, which is beneficial for the roller b3 to press down the strip-shaped polyethylene material, so that the strip-shaped pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com