Carbon fiber gas cylinder hydrostatic test device and hydrostatic test method

A carbon fiber gas cylinder, hydrostatic test technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of low drying efficiency, low testing efficiency, low testing accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

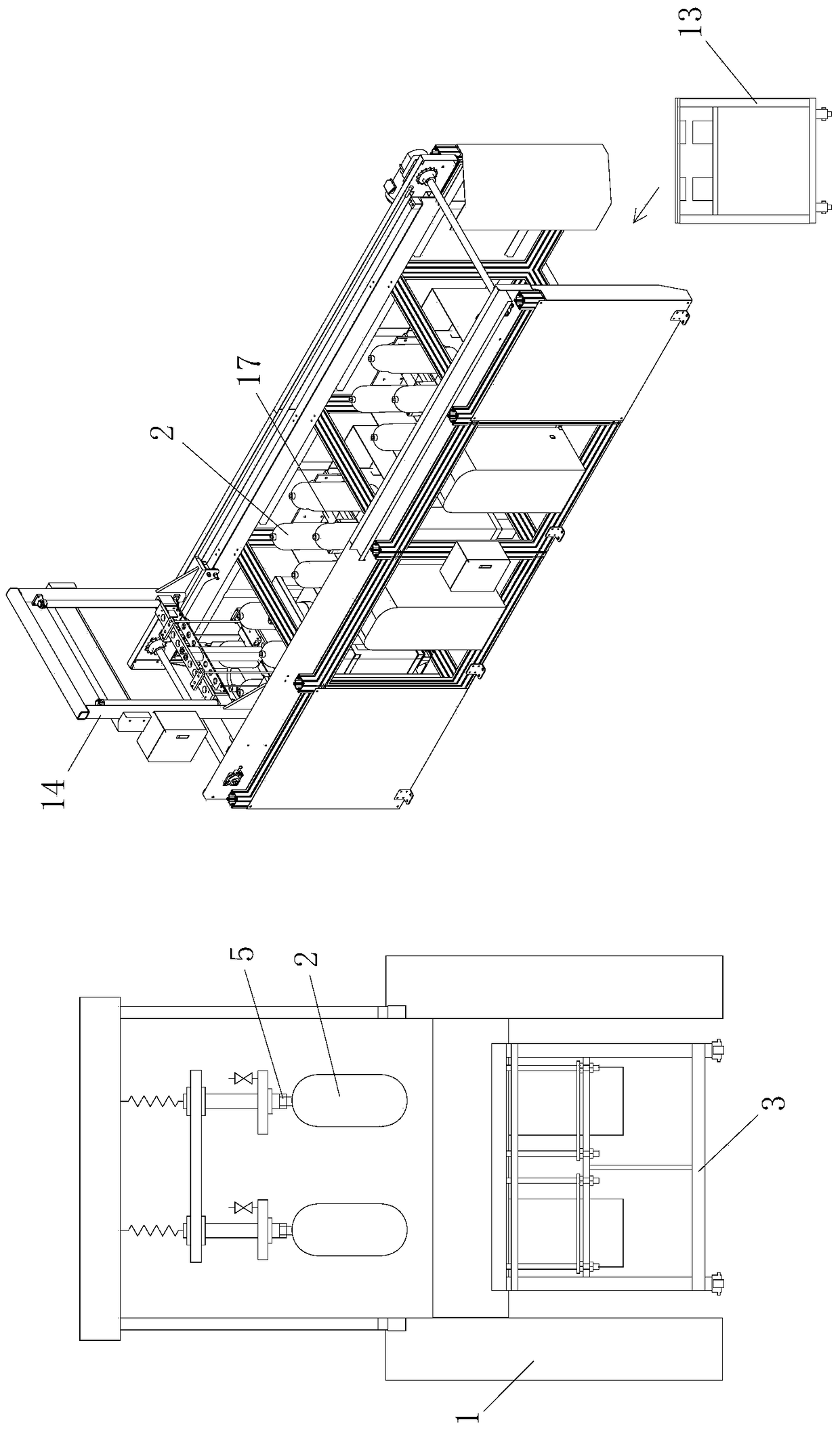

[0125] Such as figure 1 As shown, the carbon fiber gas cylinder hydraulic test device of the present invention includes a hydraulic test device for testing the deformation and pressure bearing capacity of a plurality of tested gas cylinders 2 and a water tank located at the rear side of the hydraulic test device. Pressure auxiliary test device.

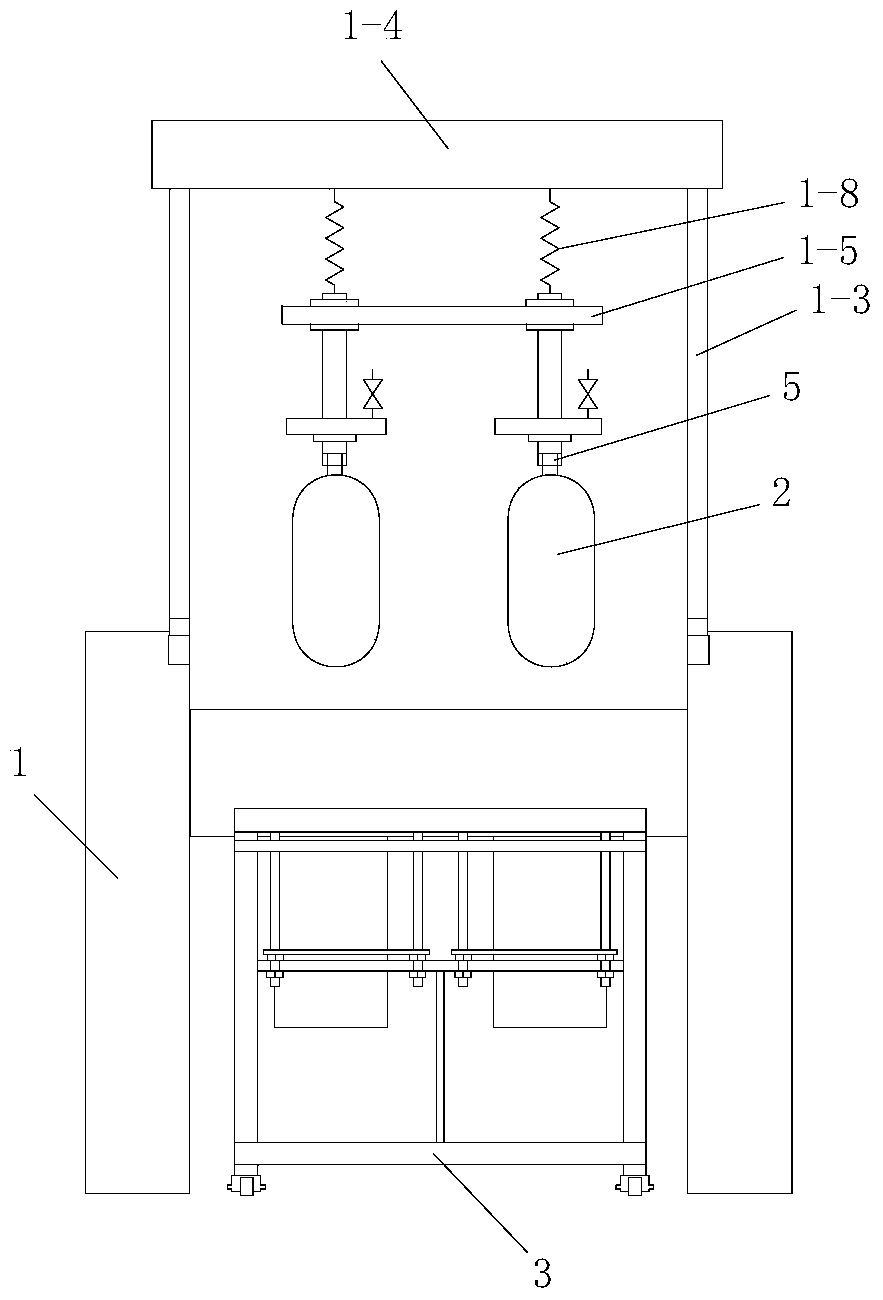

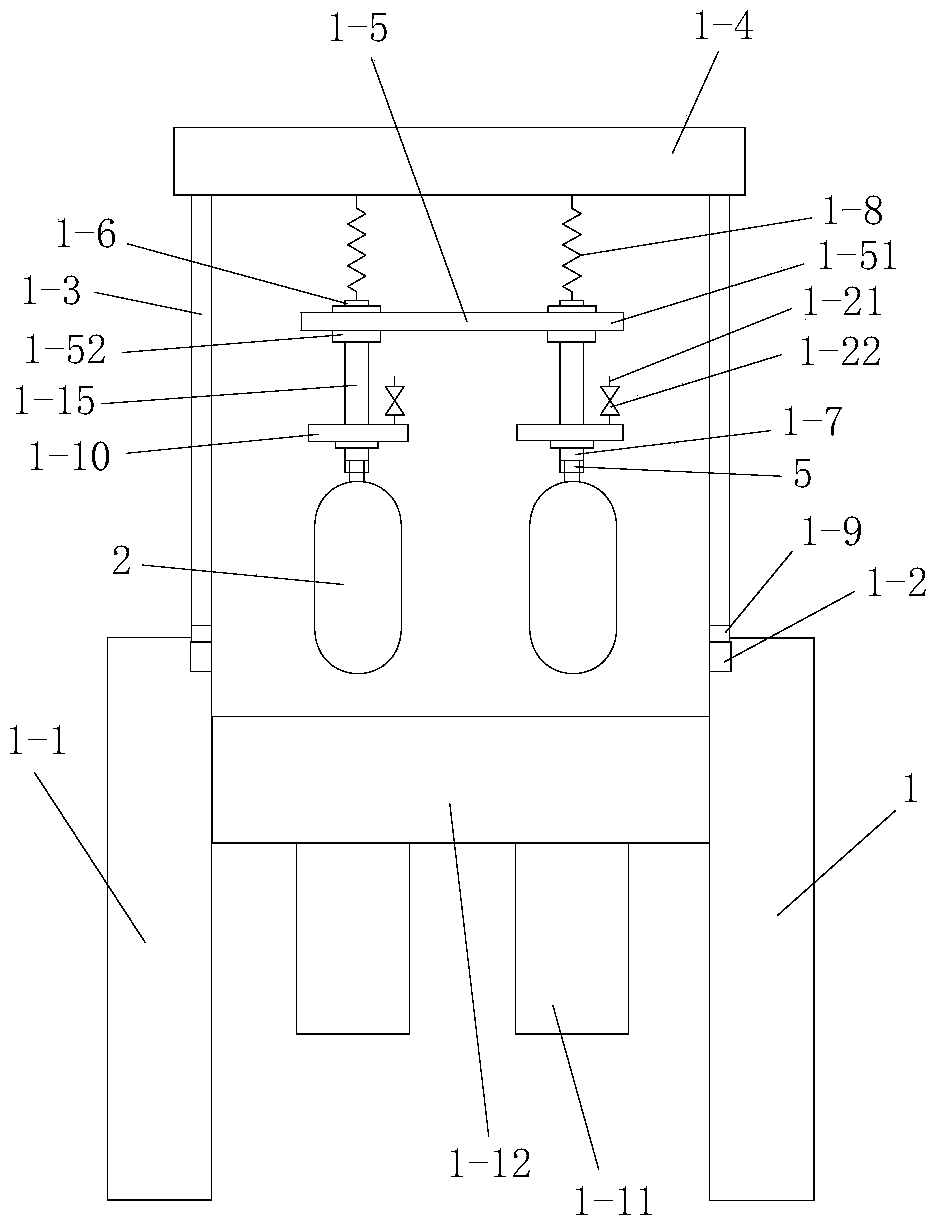

[0126] combine Picture 1-1 , the hydraulic testing device includes a test frame 1, a test console 4 positioned at one side of the test frame 1, a pressurizing device for pressurizing the gas cylinder 2 to be tested, and a test box installed on the test frame 1 And for a plurality of tested gas cylinders 2 to be stably placed and can be tested gas cylinders 2 to be moved to the test trolley 3 on the front side of the test frame 1, a plurality of said tested gas cylinders 2 mounted on the test trolley 3 are in the form of Lay out vertically. The gas cylinder 2 to be tested is a carbon fiber gas cylinder, and a sealing joint 5 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com