Construction method for water pump house foundation of frame structure

A frame structure and foundation construction technology, which is applied in infrastructure engineering, pump stations, water supply devices, etc., can solve the problems of difficult construction and compaction of water pump houses, and saves the process of supporting and dismantling formwork, saving engineering quantities, and saving materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

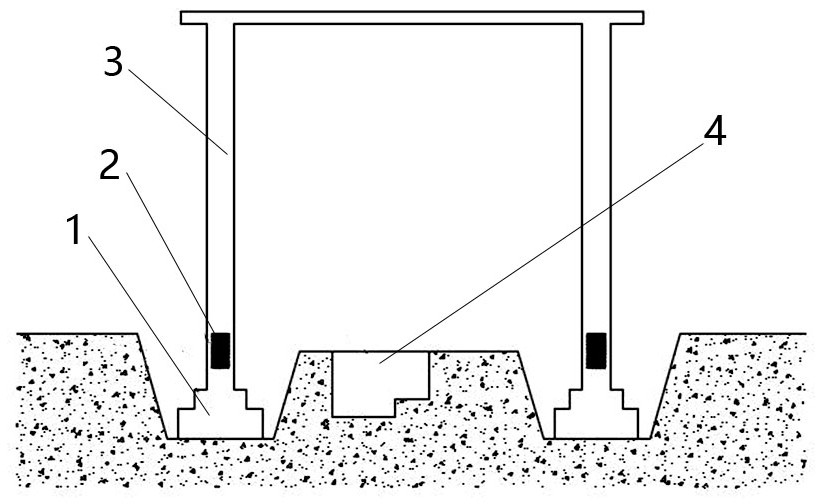

[0020] like figure 1 Shown, the present invention is achieved in that a kind of frame structure water pump house foundation construction method comprises the following steps:

[0021] a. Set out the frame foundation 1 of the pump house, excavate the foundation pit of the frame foundation 1, and keep the soil layer in the middle of the frame without excavation.

[0022] b. The frame foundation 1 is constructed in the foundation pit, and the frame foundation 1 is maintained until the formwork is removed.

[0023] c. The soil layer of the frame foundation 1 is rammed and filled in layers, and the backfill height of the soil layer is below the ground beam 2 and below the indoor floor structure layer.

[0024] d. The foundation pit of the equipment foundation 4 is excavated, the foundation pit of the equipment foundation 4 is manually trimmed, and the soil wall of the foundation pit of the equipment foundation 4 is used as a soil mold for pouring construction.

[0025] e. Set up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com