Adjustable dry hanging structure for large-size vitrified tile on wall surface and installation method

A vitrified brick and adjustable technology, applied in building construction, covering/lining, construction, etc., can solve the problems of unadjustable vitrified brick dry-hanging structure, shorten the construction period, weaken the pressure difference resistance, reduce the construction effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

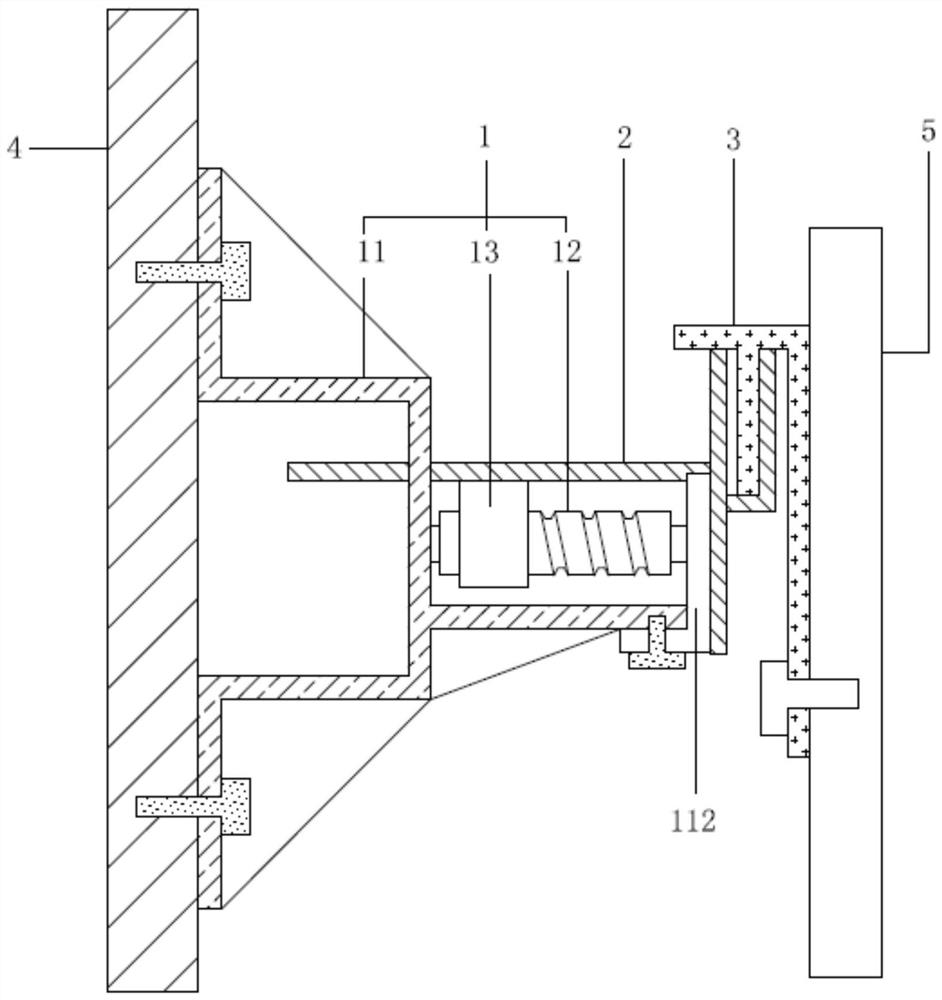

[0030] see Figure 1 to Figure 4 , the figure shows an adjustable dry-hanging structure for large-scale vitrified tiles on the wall provided by Embodiment 1 of the present invention, including a torque-adjusting mechanism 1, a connecting piece 2 and a dry-hanging piece 3, and the torque-adjusting mechanism 1 includes a mounting seat 11 , screw torque adjusting rod 12 and sliding seat 13, mounting base 11 is fixedly installed on the base wall 4, screw torque adjusting rod 12 is rotatably installed on the mounting base 11, and spiral torque adjusting rod 12 is perpendicular to base wall 4, The sliding seat 13 is sleeved on the screw torque rod 12, the connecting piece 2 is fixedly installed on the sliding seat 13, the dry hanging piece 3 is fixedly installed on the vitrified tile 5 through the expansion bolt, and the dry hanging piece 3 is fastened on the connecting piece 2.

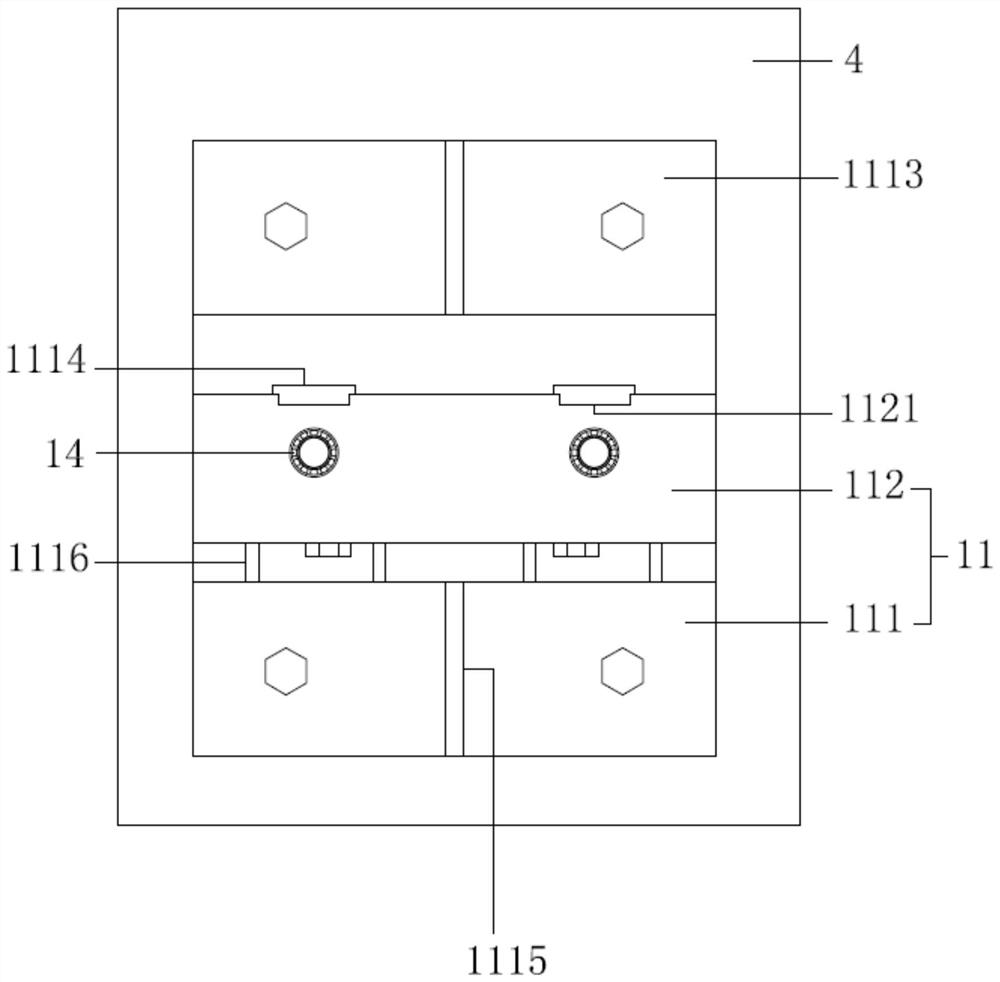

[0031] Specifically, see Figure 1 to Figure 4 , The mounting seat 11 is provided with two helical tor...

Embodiment 2

[0042] see Figure 1 to Figure 4, the figure shows an adjustable dry-hanging structure for large-scale vitrified bricks on the wall provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments : the top of the movable mounting plate 112 is provided with a groove 1121, and the connector 2 is slidably connected in the groove 1121;

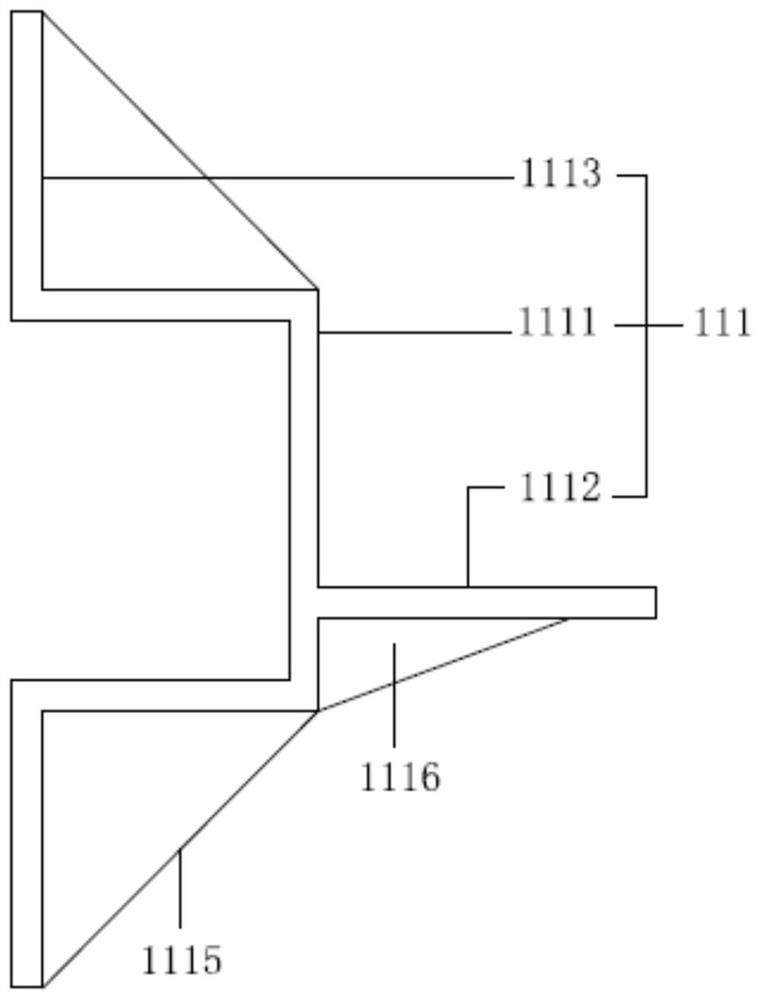

[0043] The base 111 includes a fixing part 1111 and a supporting plate 1112. The cross section of the fixing part 1111 is c-shaped, and the opening direction faces the base wall 4. The edge of the fixing part 1111 is bent to form a skirt 1113, and the skirt 1113 is fixedly installed on the base wall. 4; the fixing part 1111 is provided with a through hole 1114, and the connecting member 2 is passed through the through hole 1114.

[0044] The top of the movable mounting plate of the mounting seat is provided with a groove, and the bas...

Embodiment 3

[0046] see Figure 1 to Figure 4 , the figure shows an adjustable dry-hanging structure for large-scale vitrified bricks on the wall provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments : a first reinforcement plate 1115 is arranged between the skirt 1113 and the fixed portion 1111, one side of the first reinforcement plate 1115 is fixedly mounted on the skirt 1113, and the other side is fixedly mounted on the fixed portion 1111; the supporting plate 1112 is connected with the fixed A second reinforcing plate 1116 is disposed between the parts 1111 , one side of the second reinforcing plate 1116 is fixedly installed on the bottom of the supporting plate 1112 , and the other side is fixedly installed on the fixing part 1111 .

[0047] A first reinforcing plate is arranged between the skirt of the base and the fixing part; a second reinforcing plate is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com