Array type sound wave scanning high-precision drilling imaging method and device

A borehole imaging, high-precision technology, applied in the direction of earthwork drilling, measurement, borehole/well components, etc., can solve the problems of distortion and low precision of acoustic borehole imaging results, achieve rich detection data, simplify structural components, Detecting Adaptive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with accompanying drawing and implementation example the present invention is further described:

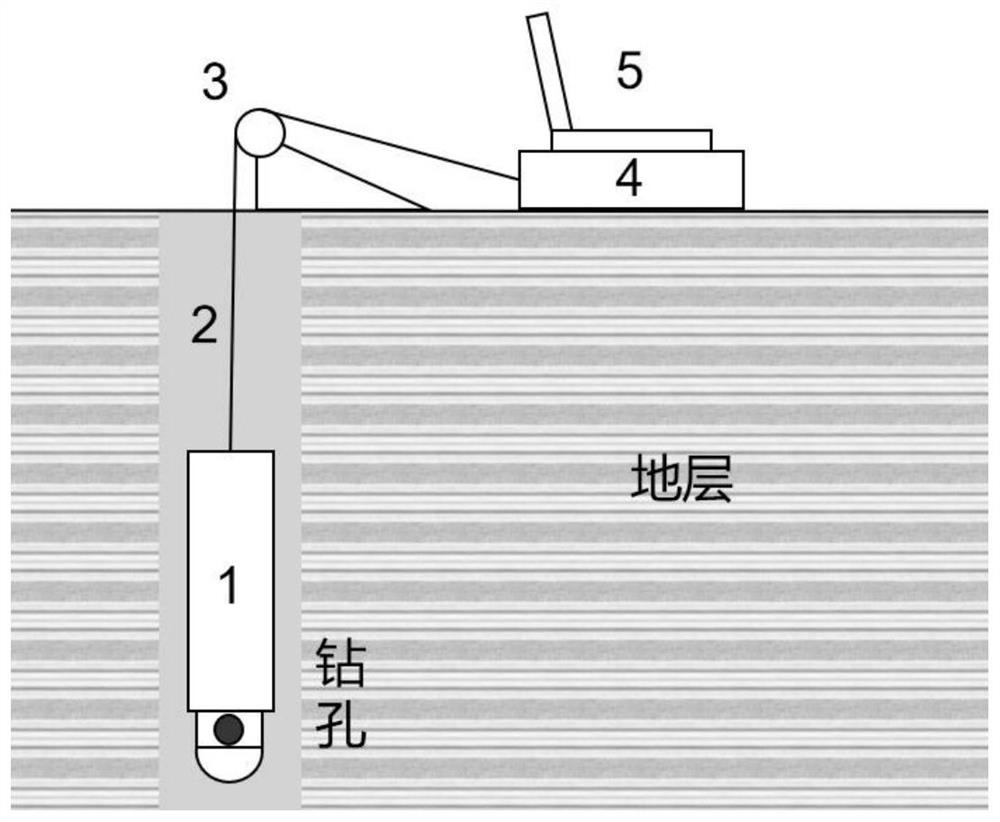

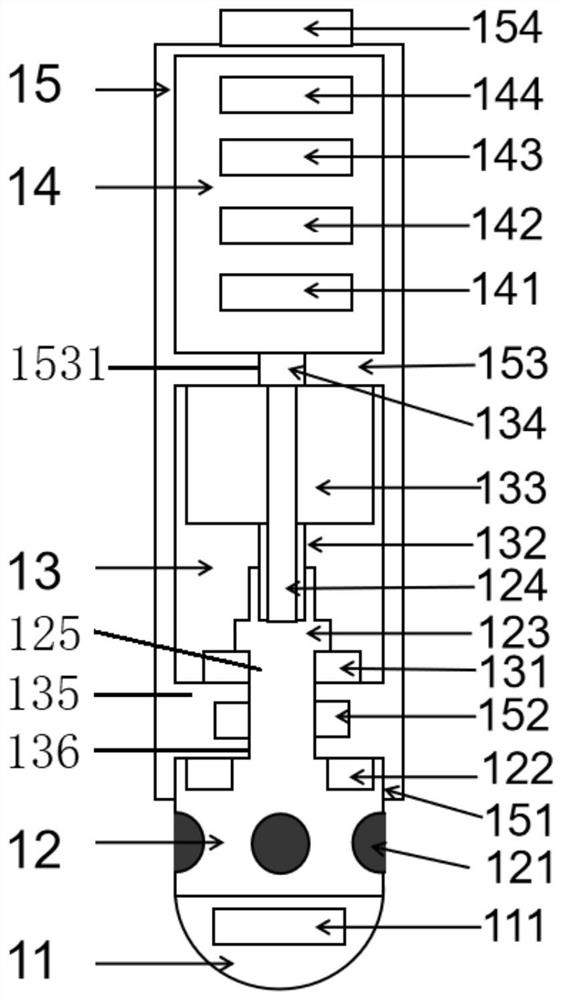

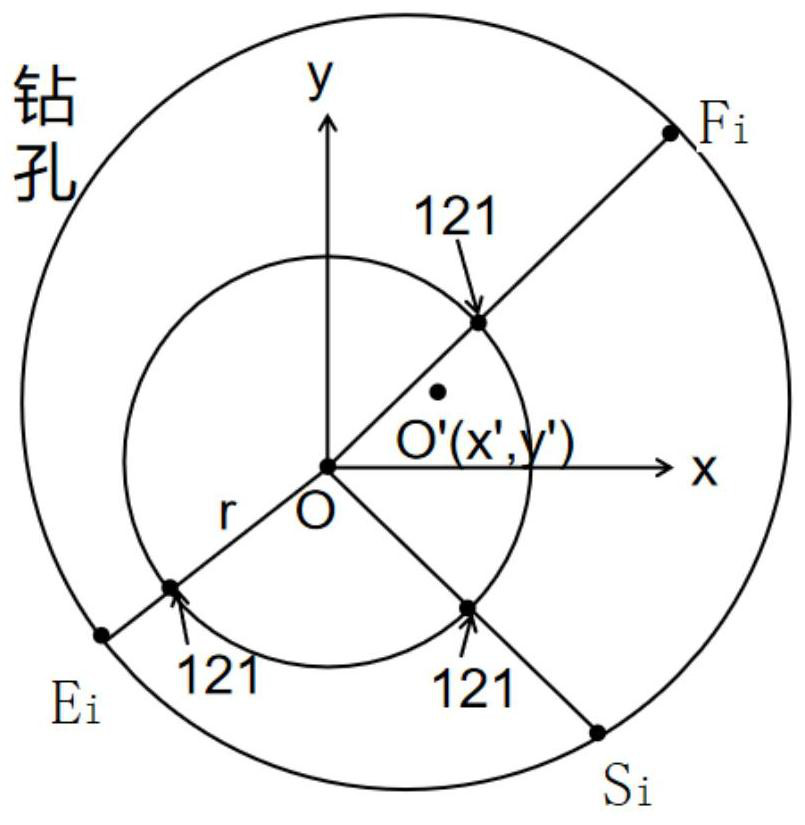

[0059] A high-precision borehole imaging device for array acoustic wave scanning, which mainly includes five parts: an in-hole probe 1, a transmission cable 2, a depth encoder 3, an integrated control box 4, and an industrial computer 5;

[0060] Such as figure 1 As shown, the borehole probe 1 is mainly responsible for collecting data in the borehole. The borehole probe 1 is placed inside the borehole to work. The transmission cable 2 is mainly used to upload the data of the borehole probe 1 to the ground. The depth encoder 3 is mainly used for The depth of the borehole where the probe 1 is located is collected in real time, the depth encoder 3 is usually placed in the borehole, the transmission cable 2 is connected to the integrated control box 4 on the ground, and the integrated control box 4 is used for data demodulation and power supply , the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com