Composite type efficient coal mining machine with pre-screening function

A composite, pre-screening technology, applied in screening, earth-moving drilling, slitting machinery, etc., can solve problems such as the impact of coal and pulverized coal ex-factory prices, social environment, dust, etc., to ensure mining efficiency and The effect of conveying reliability, ensuring environmental protection, and improving screening capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

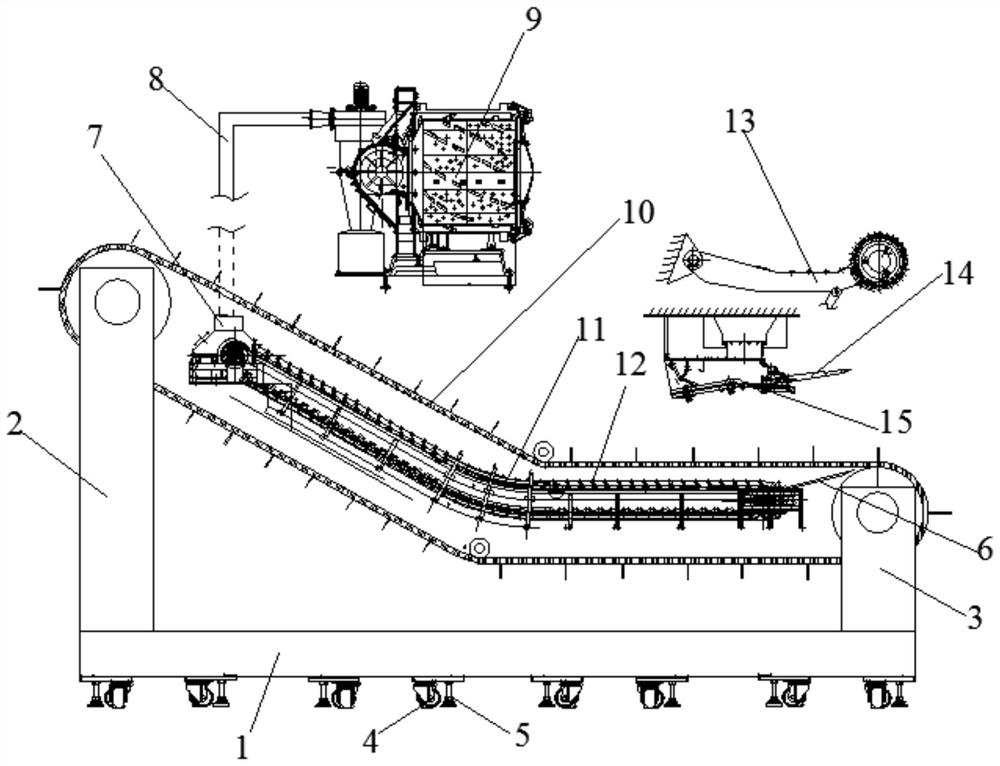

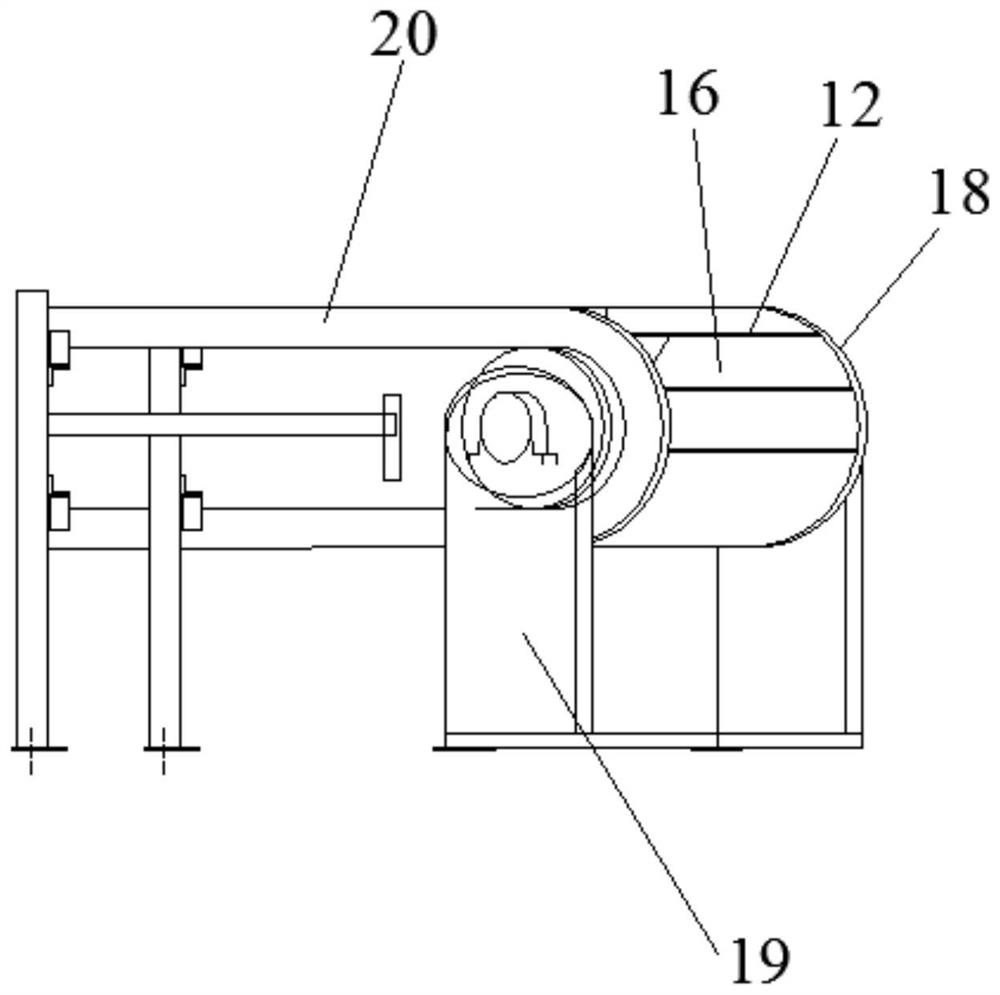

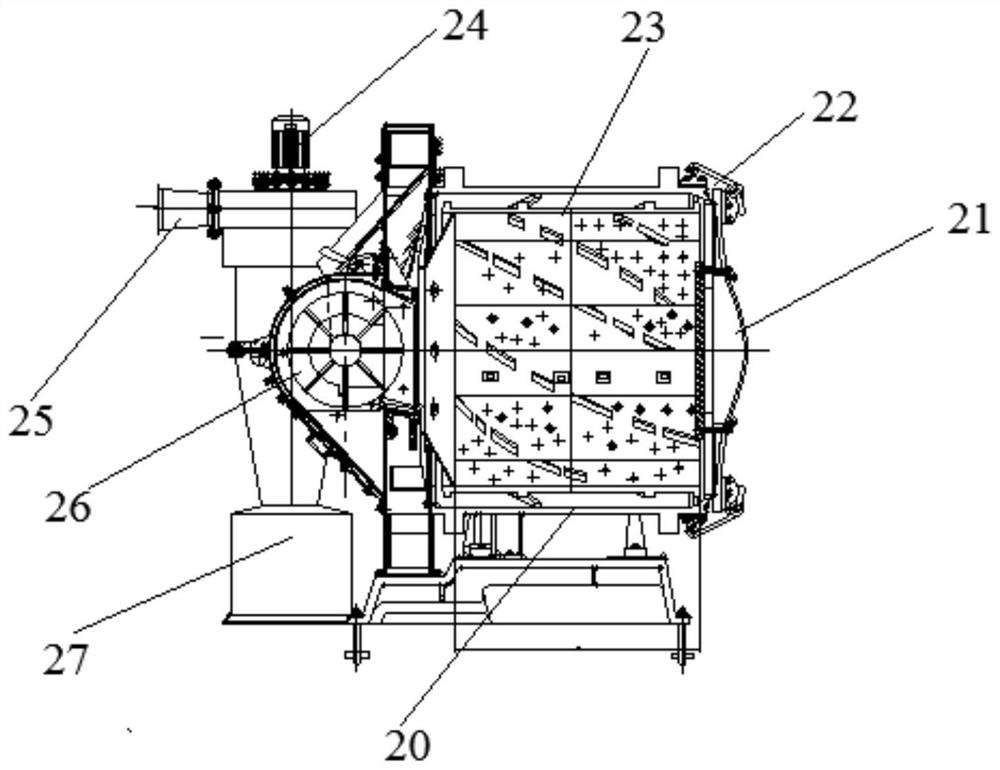

[0027] see Figure 1~4 , in an embodiment of the present invention, a compound high-efficiency coal mining machine with a pre-screening function, which includes an underframe 1, a long support 2, a short support 3, a coal block conveying and screening mechanism 10, and a pulverized coal receiving and conveying mechanism 11 , coal dust suction charging mechanism 9, coal mining drill bit 14 and coal mining sawing cutter 13, wherein, the bottom of described underframe is provided with the walking mechanism that is convenient to it is moved forward, and the direction of described underframe is towards the The short support is provided on one side of the coal seam, and the long support is provided on the side of the bottom frame away from the coal mining seam. 10. The coal block conveying and screening mechanism 10 is an annular conveyor, and the inner side of the annular area of the coal block conveying and screening mechanism 10 is provided with the pulverized coal material rec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap