Washing system of slurry shield cutterhead and construction method of washing system

A technology for flushing system and shield cutter head, which is applied to the cleaning method using liquid, chemical instruments and methods, cleaning methods and utensils, etc., and can solve the problems such as difficulty in guaranteeing the flushing effect of the cutter head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

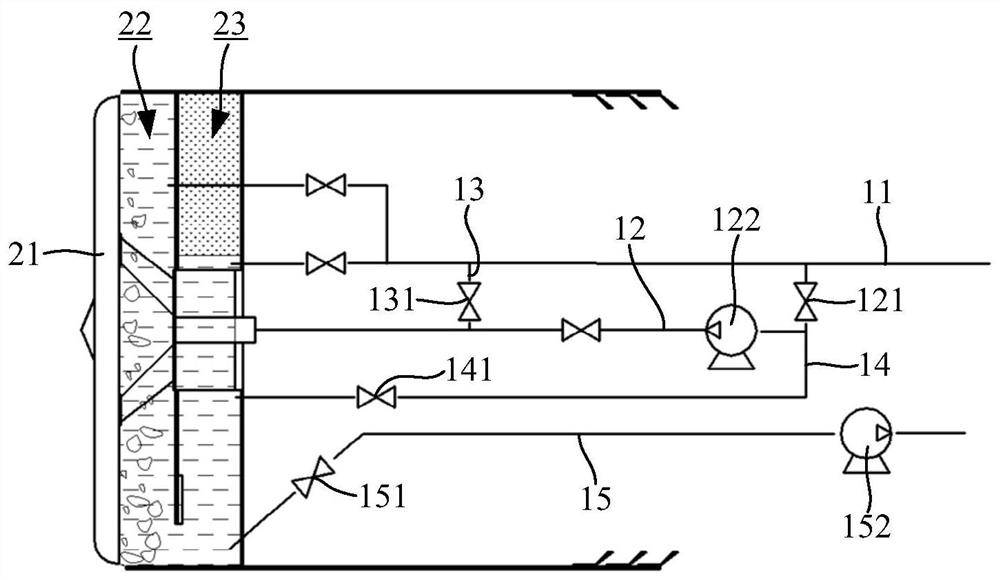

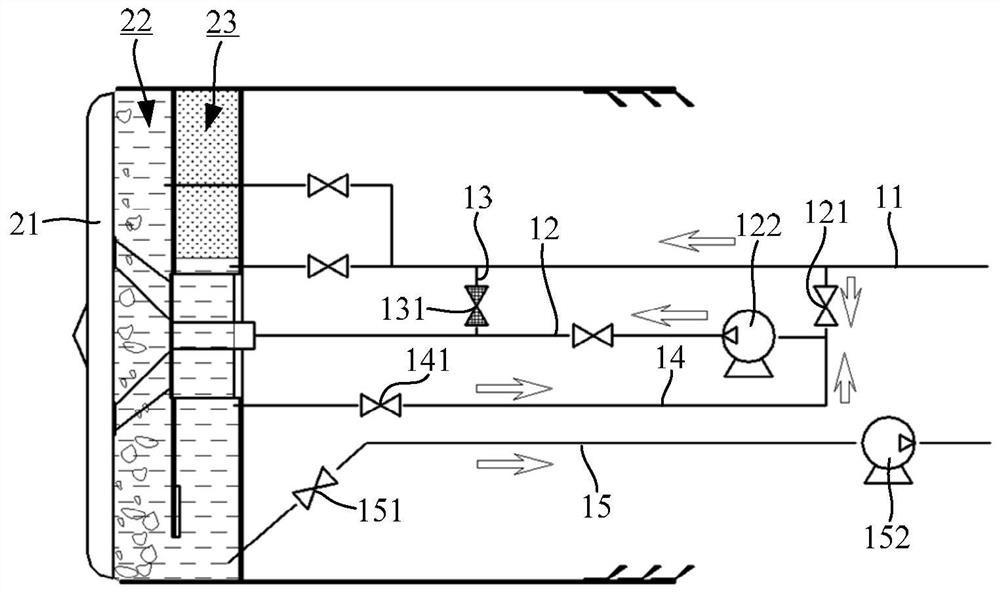

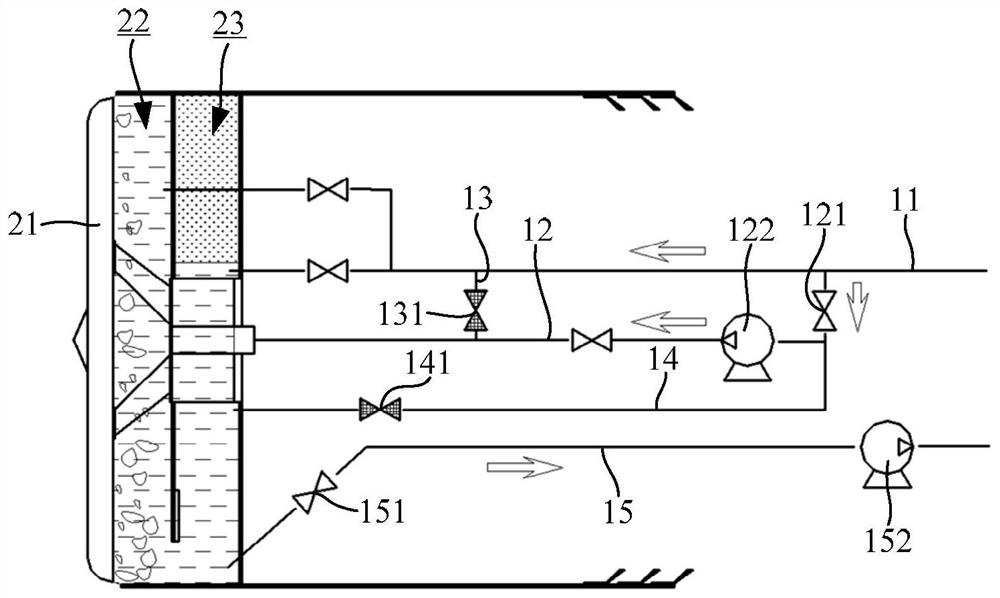

[0033] refer to figure 1 , the present invention provides a muddy water shield cutter head flushing system and its construction method, by setting a circulation pipe to pump the muddy water with less upper sediment in the air cushion chamber to the center pipe for flushing the center of the cutter head In this way, the muddy water separated from the mud pipe by the central pipe can be reduced, the flow of muddy water in the mud pipe can be guaranteed, and the cleaning effect of other parts of the shield can be avoided due to the muddy water in the mud pipe being separated by the central pipe, which solves the problem It is difficult to guarantee the flushing effect of the cutter head. The improvement of the flushing system can ensure the flow of muddy water, thereby improving the cleaning effect of the center of the cutter head and other parts,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com