Method for producing a separation product containing predominantly hydrocarbons with two carbon atoms

A carbon atom, product technology, used in the field of recovery of separation products and equipment mainly containing hydrocarbons with two carbon atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

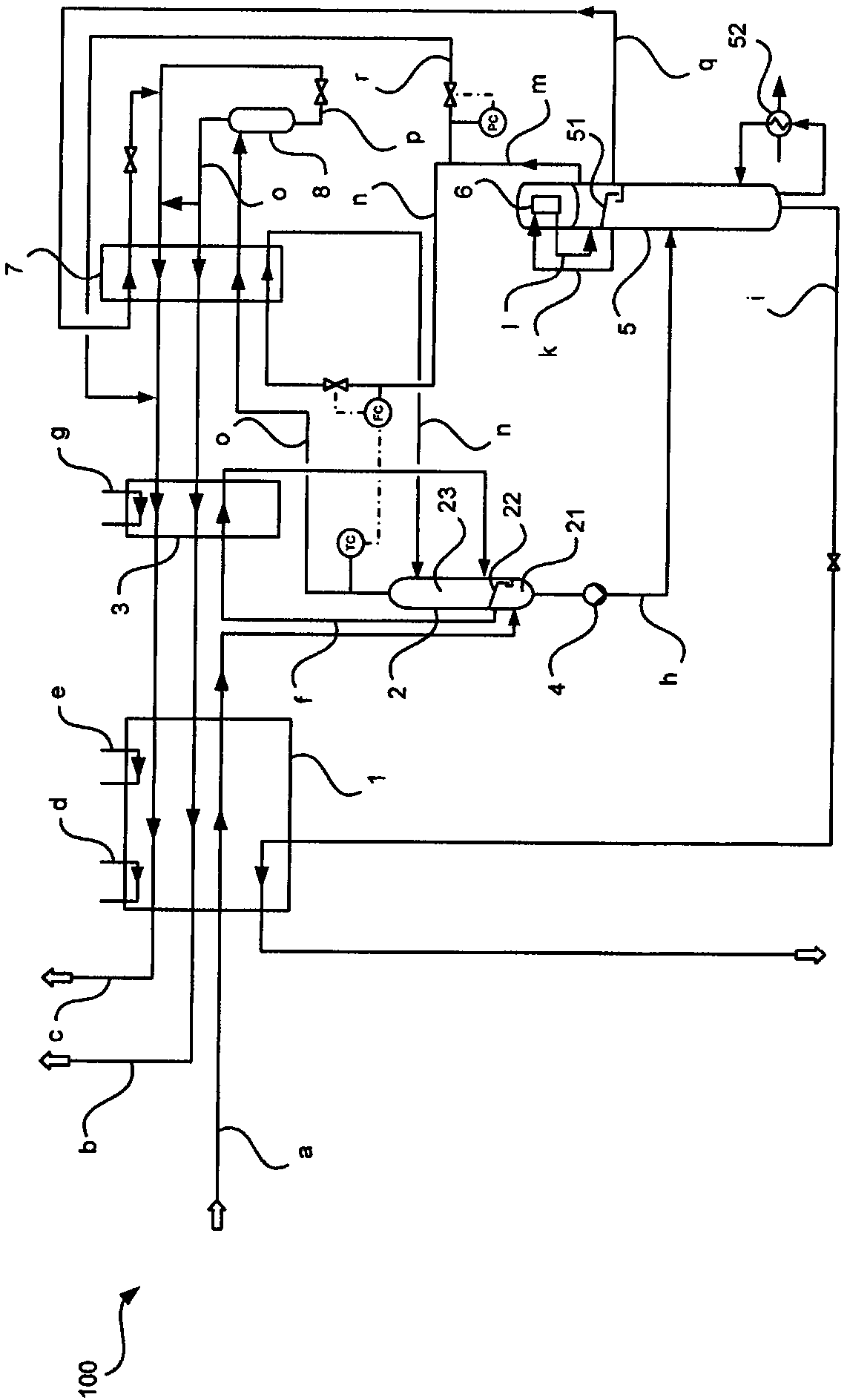

[0047] exist figure 1 In , a method according to a particularly preferred embodiment of the present invention is illustrated in the form of a schematic process flow diagram, which is designated as a whole at 100 . Explanations relating to the method 100 apply in a similar manner to the corresponding apparatus, so that when reference is made to method steps, corresponding explanations also correspond to parts of the apparatus and vice versa.

[0048] In process 100, a gaseous mixture mainly containing methane, hydrogen and hydrocarbons with two carbon atoms, which may have previously been hydrated, for example, to convert previously contained acetylene, and is formed from cracked gases of a steam cracking process not shown here, Supplied in gaseous form as an isolated feedstock.

[0049] The separated feed in the form of stream a is cooled in heat exchanger 1 to about A pressure level of 34.9 bar (herein referred to as "first pressure level") starting from a temperature level o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com