Adjustable and detachable self-adaptive floating buffering structure

A cushioning structure and self-adaptive technology, applied in the field of hydraulic cylinder cushioning, can solve problems such as commissioning or repairing mining area complaints, increased lifting system failures, and buffering effects that cannot be fully worked, achieving shortened downtime, good buffering effects, and refined The effect of cushioning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

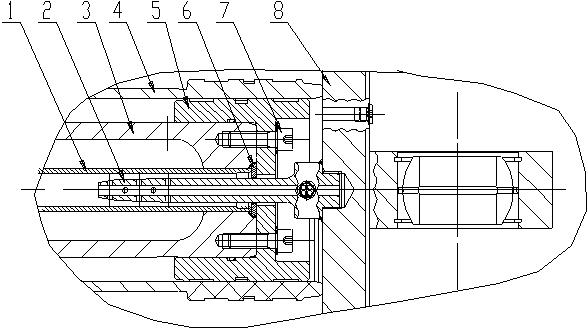

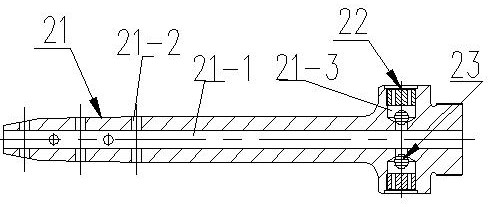

[0025] combine figure 1 with figure 2 As shown, an adjustable and detachable self-adaptive floating buffer structure, a piston 5 is installed at the inner end of the hollow piston rod 3, and the circumferential surface of the piston 5 is slidingly matched with the inner wall of the secondary sleeve 4; a buffer plunger is fixed at the center of the cylinder bottom 8 component2.

[0026] The improvements of this embodiment are:

[0027] The hollow piston rod 3 is sleeved with a sleeve 1, and the sleeve 1 is welded to the inner wall of the hollow piston rod 3 to supply oil to the rodless cavity. The inner end of the hollow piston rod 3 is provided with a notch, and a buffer ring 6 is floatingly installed in the notch at the inner end of the hollow piston rod 3 . The piston 5 is in the shape of a cylinder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com