Rotary phase adjusting coupling and application method thereof

A coupling and shaft joint technology, which is applied in the field of mechanical transmission, can solve the problems of the ratchet mechanism such as difficulty in manufacturing, limited practicability, and only one-way adjustment, and achieve the effects of simple structure, low cost, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention.

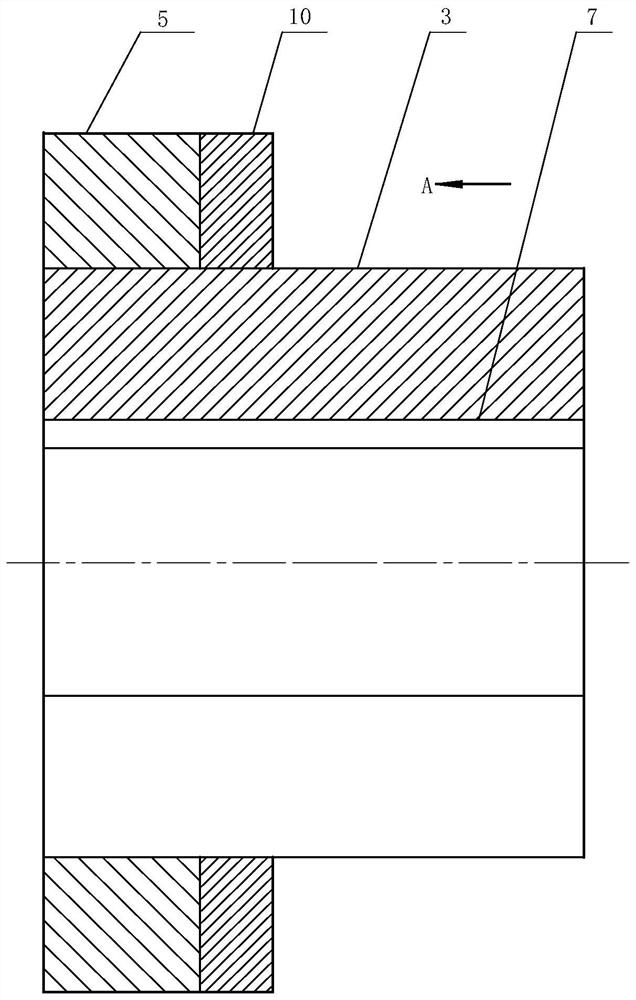

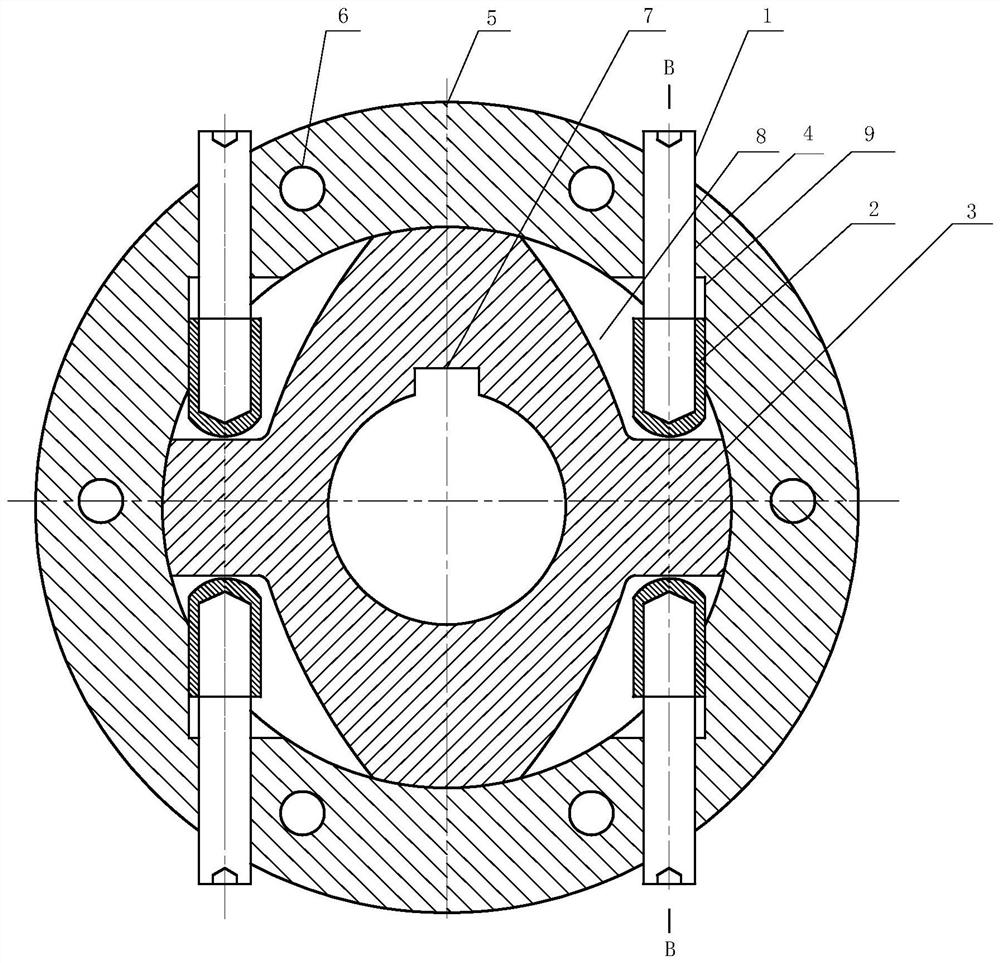

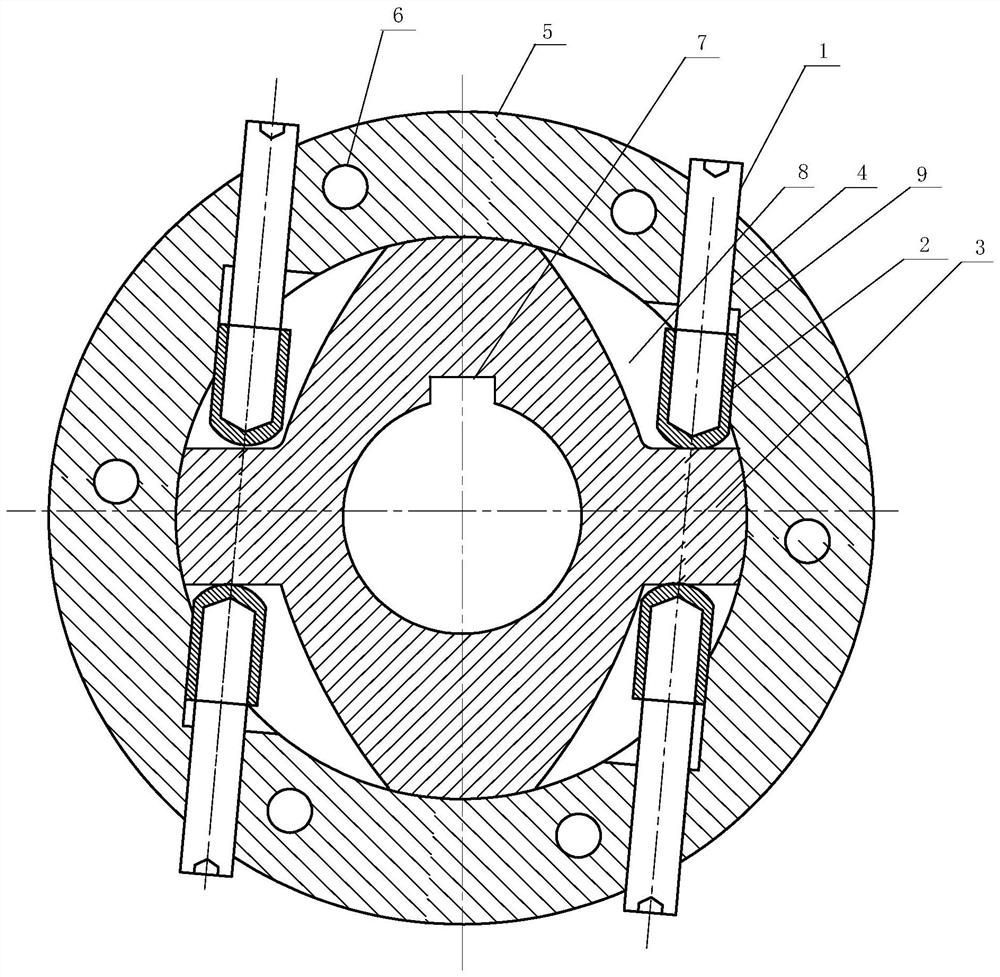

[0030] Such as Figure 1 to Figure 4 As shown, the rotary phasing coupling of the present invention includes: a coupling stator 5, a coupling rotor 3, an adjusting bolt 1, an adjusting plug 2 and a coupling pressure ring 10, and the coupling rotor 3 is mounted on the coupling In the joint stator 5, a keyway 7 is opened in the coupling rotor 3, and the coupling rotor 3 is connected with the connecting shaft through the keyway 7 and the key. The coupling stator 5 is connected to the rotary member through the fastening bolt hole 6 on it, and it is characterized in that the coupling stator 5 and the coupling rotor at the end where the coupling stator 5 and the coupling rotor 3 are in contact 3 are respectively provided with four rotor slots 8 and four stator slots 9, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com