Blasting type pressure relief device with spring actuator

A pressure relief device and actuator technology, applied in the direction of valve heating/cooling device, valve device, function valve type, etc., can solve the problem that the device cannot realize the function, etc., and achieve easy observation, low downtime cost and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

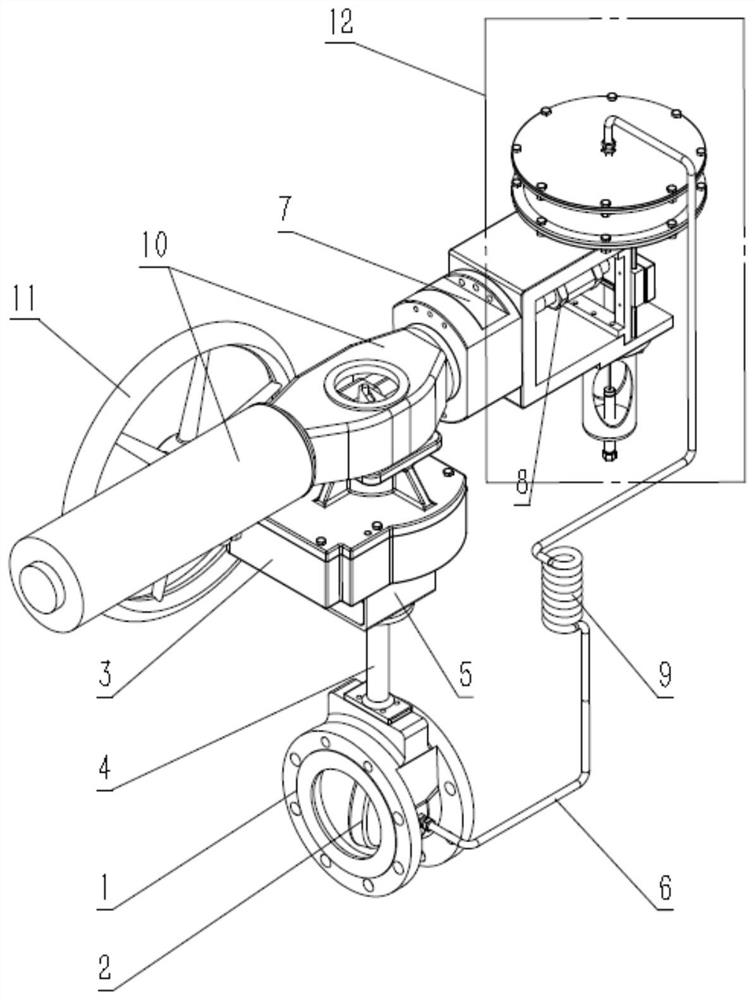

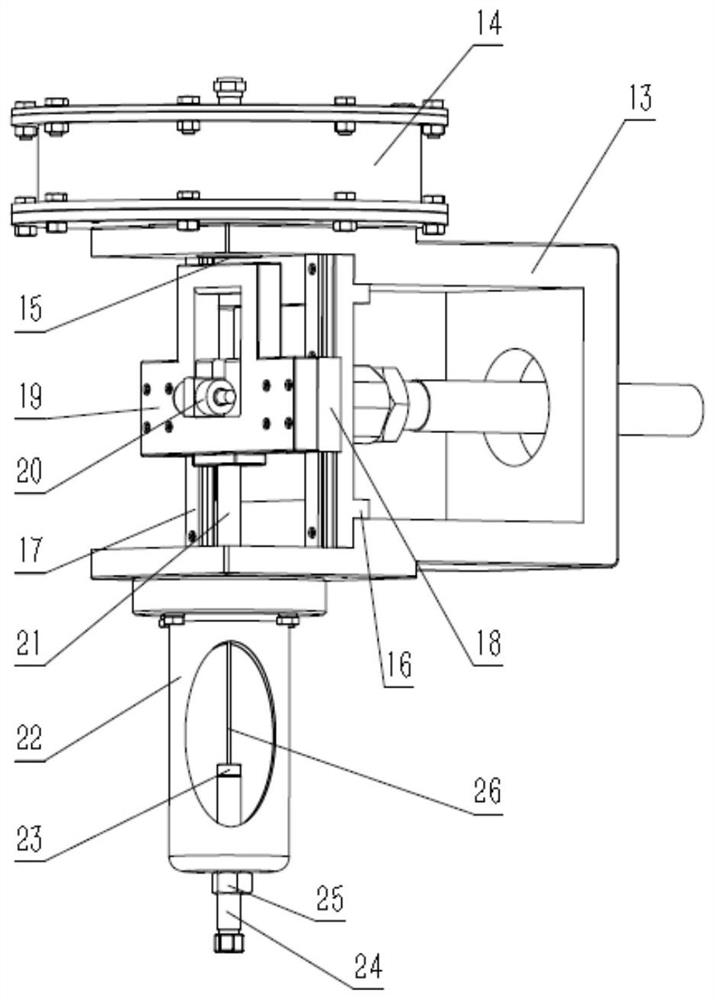

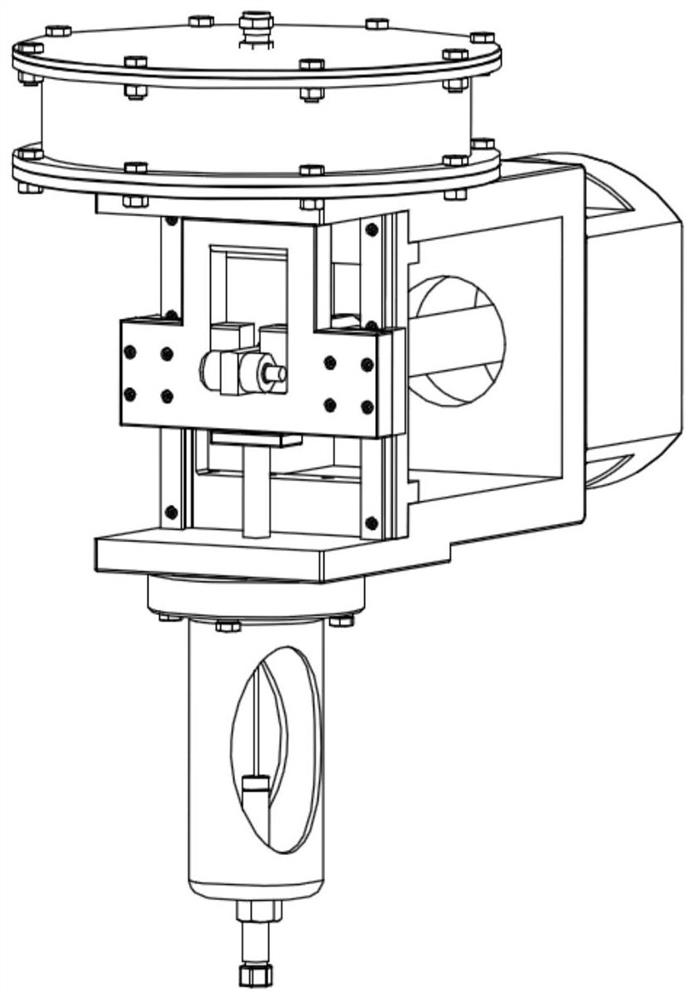

[0052] Such as Figure 1~6 As shown, the present invention is a blasting type pressure relief device with a spring actuator, the pressure relief device is composed of a pilot valve, a main valve, a spring actuator 10, a heat exchange tube 9 and a connecting pipeline;

[0053] The main valve, the pilot valve, and the spring actuator 10 are connected together through the bracket 5;

[0054] Through the pressure introduction pipe 6, the medium upstream of the main valve enters the cylinder 14 in the pilot valve through the heat exchange pipe 9, and through the structure of the heat exchange pipe 9, the temperature of the working medium is adjusted to normal temperature through natural convection heat exchange, so as to ensure that the pressure relief device can operate Good sealing is achieved under severe working condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com