Method for processing brake friction heat load data of automobile brake disc

A technology of automobile braking and processing methods, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of simple and single thermal loading of brake discs, and cannot accurately feedback the magnitude of frictional heat, and achieve reliable processing. method, the effect of improving the calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

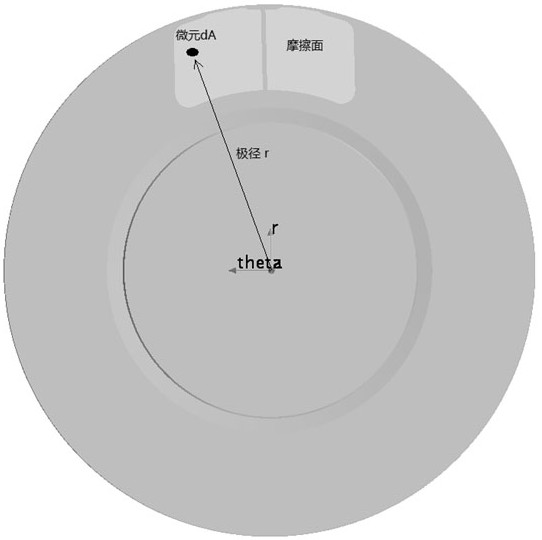

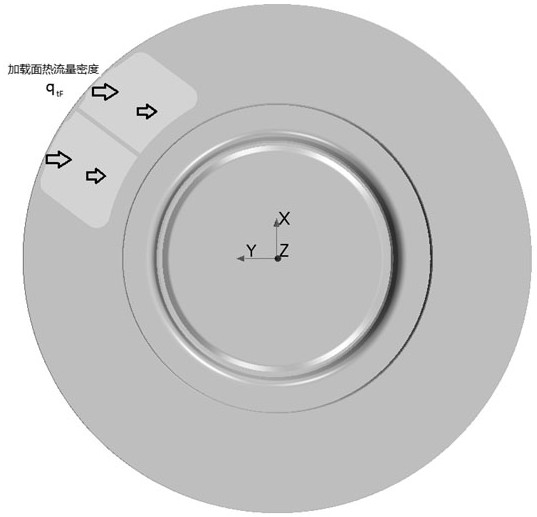

[0030] Example: see Figure 1-4 .

[0031] A method for processing brake friction heat load data of an automobile brake disc, the processing steps are as follows:

[0032] S1. Analyze the energy transformation during the braking process of the automobile brake disc;

[0033] S2. Calculate the total thermal power of the friction of the front and rear brake discs of the automobile;

[0034] S3. Calculating the proportionality constant k between the thermal power produced per unit area of the brake disc of the automobile and the pole radius r;

[0035] S4. Obtain the heat flux q of the friction surface of the automobile brake disc tF function.

[0036] The energy transformation in the analysis of the automobile brake disc braking process described in step S1 is specifically:

[0037] 1) During the braking process of the brake disc, the kinetic energy reduction rate of the whole vehicle is Mv t a;

[0038] 2) Gravity work power on the ramp is ±Mgsinθ.v t , uphill is nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com