Method for Pretreating Nano Hollow Silicon/Carbon Electrode Materials of Electrochemical Energy Storage Devices with Solvents and Solvent-in-Silicon Particles

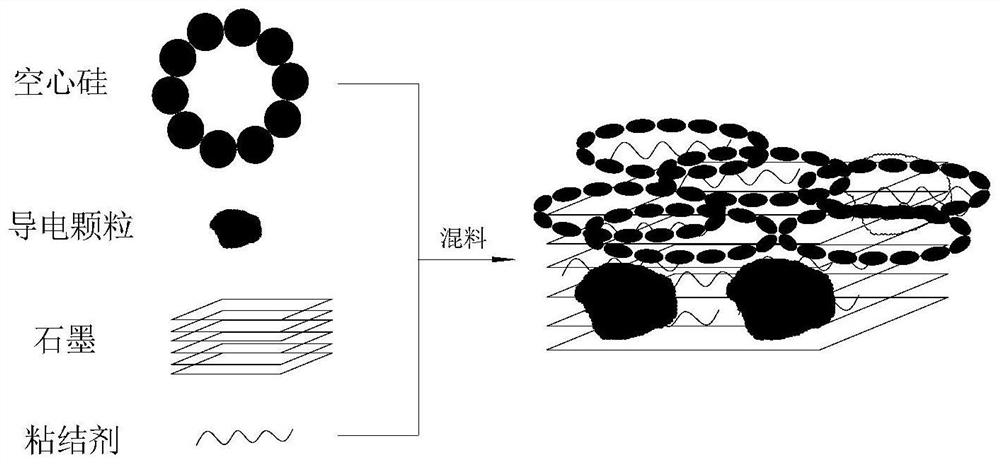

An energy storage device, hollow silicon technology, applied in nanotechnology for materials and surface science, battery electrodes, electrochemical generators, etc. It can improve the charge and discharge capacity, solve the battery capacity decay, and improve the cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

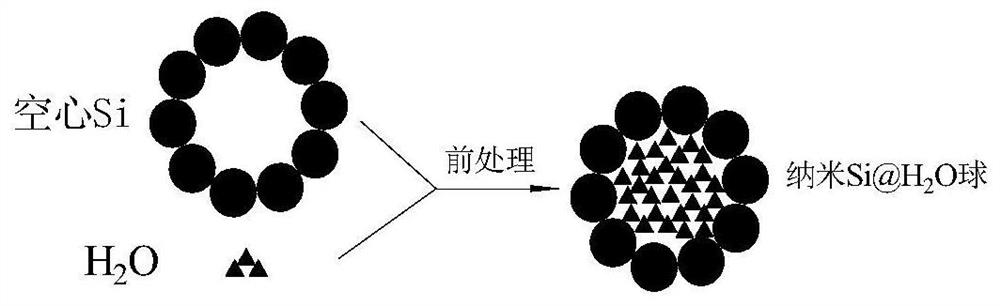

[0068] Example 1: Preparation of nanoscale water-in-silicon particles

[0069] Using the method in CN105705460A, 20 g of nanoscale hollow silicon for electrodes was prepared.

[0070] Weigh 4g of nanoscale hollow silicon and place it in a vertical centrifugal disperser, and then add 40ml of deionized water. A two-stage stirring process is set up. The first stage: the stirring speed is 300r / min, which lasts for 5 minutes; the second stage: the stirring speed is 2000r / min, which lasts for 35 minutes. Thus, the nano hollow silicon and water are thoroughly mixed to obtain a solution of water-in-silicon particles.

[0071] Take half of the volume of the water-in-silicon particle solution for suction filtration, and air-dry the solid obtained by suction filtration in a fume hood at room temperature for 2 hours to obtain nanoscale water-in-silicon particles.

[0072] figure 2 A schematic diagram of the nanoscale water-in-silicon particles of the present disclosure is given.

Embodiment 2

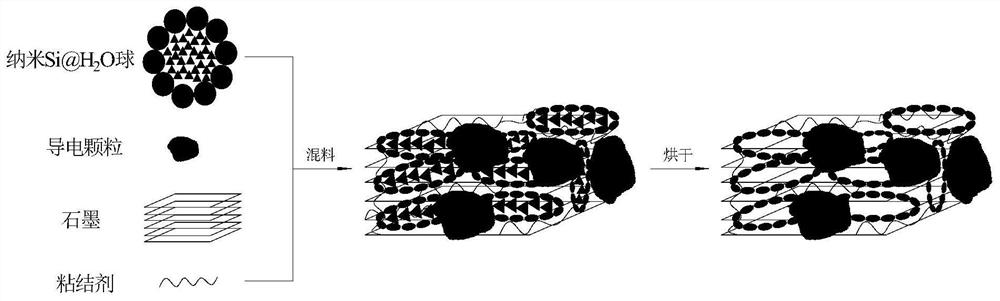

[0073] Embodiment 2: Preparation of electrodes for electrochemical energy storage devices

[0074] 1) Add 0.8 g of water-based binder to the other half of the water-in-silicon particle solution that has not been suction-filtered prepared in Example 1 above, set the stirring speed to 2000 r / min, and continue stirring for 0.5 h. Then, add 0.4g of conductive agent and 16.8g of graphite in sequence, and set up a three-stage stirring process, the first stage: stirring speed 300r / min, last 10min; second stage: stirring speed 600r / min, last 10min ; The third section: stirring speed 3000r / min, duration 3h. After thorough mixing, an electrode slurry is prepared.

[0075] 2) The electrode slurry is coated on the current collector, and then dried at 100° C. for 12 hours to obtain an electrode for an electrochemical energy storage device, and the thickness of the electrode after drying is 75 μm.

[0076] image 3 A schematic diagram of an electrode of a carbon / silicon composite accordi...

Embodiment 3

[0079] Except replacing the water in embodiment 1 and 2 with ethanol, prepare nanoscale silicon-coated ethanol particles with the same method as described in embodiment 1 and 2, and then prepare with graphite, conductive agent, organic binder electrodes for electrochemical energy storage devices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com