Drive control device and drive control method for stepping motor

A stepper motor, drive control technology, applied in motor generator control, motor parameter estimation/correction, control system, etc., can solve the problems of camera monitoring out of position, stepper motor out of step, out of step, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

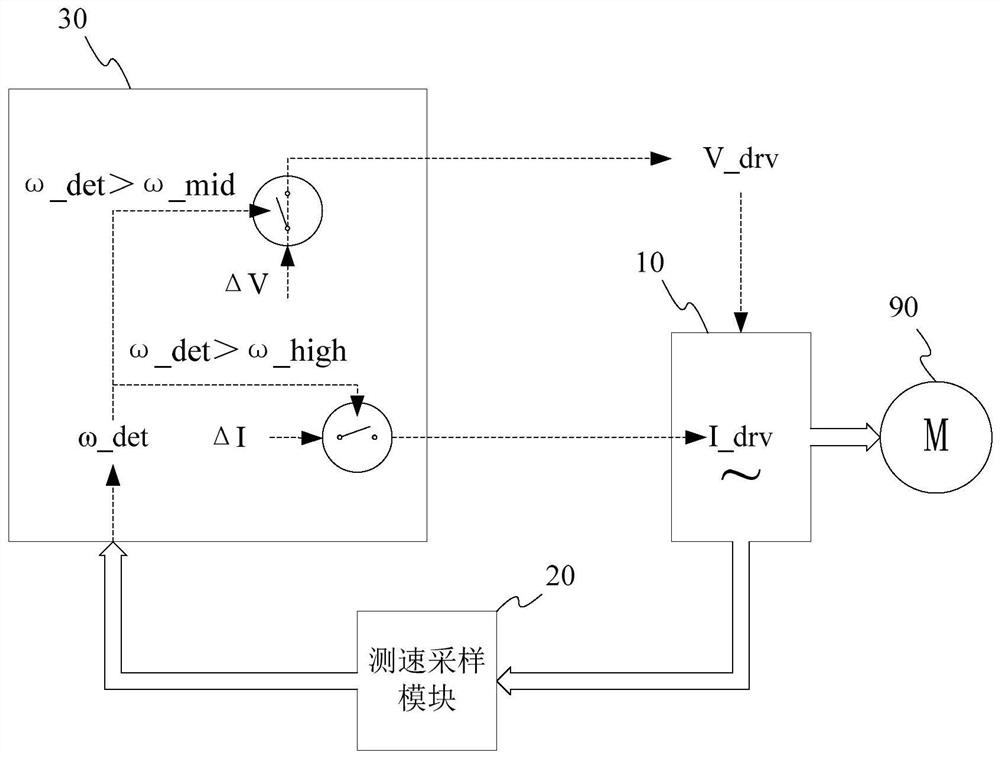

[0039] figure 1 It is a schematic diagram of the principle of a drive control device for a stepping motor in an embodiment. See figure 1 , in this embodiment, the drive control device of the stepper motor may include:

[0040] The inverter drive module 10 is used to generate the drive power to the stepper motor 90;

[0041] The speed measurement sampling module 20 is used to detect the phase voltage and phase current of the stepper motor 90 from the inverter drive module 10;

[0042] The drive control module 30 is used to utilize the phase voltage and the phase current of the stepper motor 90 detected from the inverter drive module 10 to determine the zero-crossing period of the back electromotive force of the stepper motor 90; The zero-crossing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com