Telescopic mobile terminal

A mobile terminal and telescopic technology, which is applied to the telephone structure, telephone communication, electrical components, etc., can solve the problems of reducing the service life of the mobile terminal, breaking the arc shrapnel 222, reducing the diversity of user experience, etc., so as to shorten the maintenance time. , the effect of prolonging the service life and improving the maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

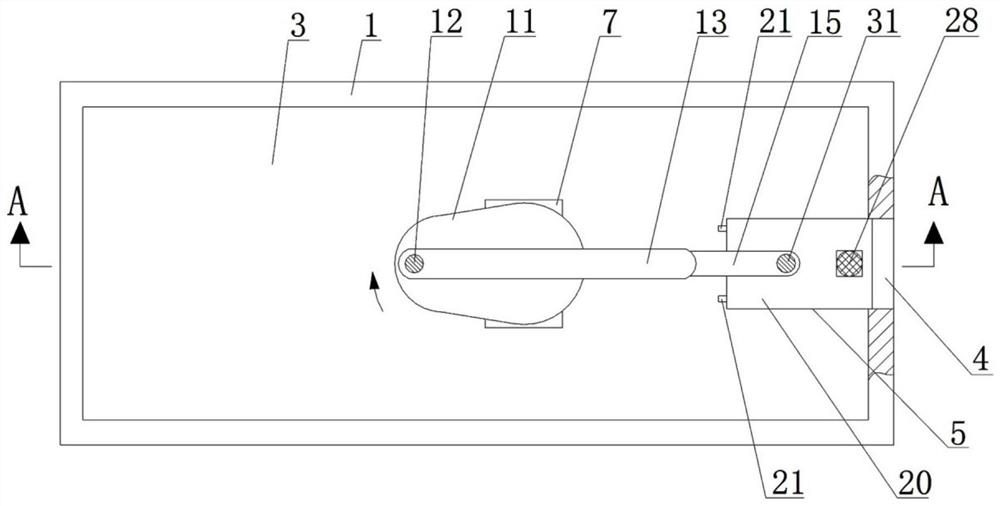

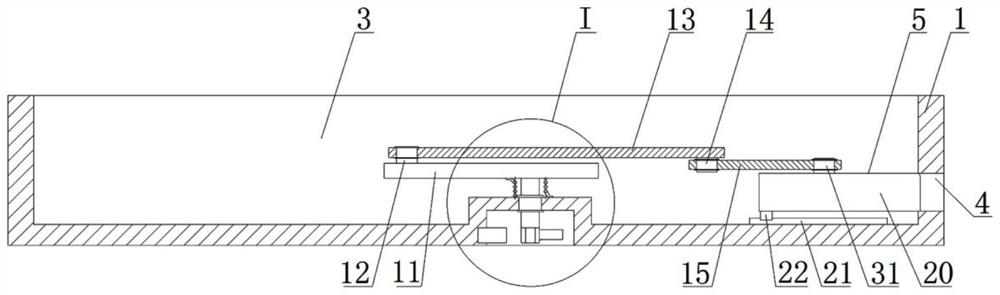

[0031] The present invention will be further described below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited to the following:

[0032] Such as Figure 1~7 As shown, a telescopic mobile terminal includes a casing 1 and a display screen 2. The display screen 2 is fixed on the top of the casing 1, and a cavity 3 is enclosed between the display screen 2 and the casing 1. A guide groove 4 is opened on the right end surface of the housing 1, and the guide groove 4 is in communication with the cavity 3. The cavity 3 is provided with a functional component 5 that can pass through the guide groove 4, and the cavity 3 is also An actuator for driving the functional assembly 5 to move linearly is provided. The actuator includes a drive shaft, a torsion spring 6 and a first groove 7 opened at the bottom of the housing 1. The drive shaft includes a sequence from top to bottom. A fixed rotating shaft 8 and a square head 9, the drive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com