Material guide device for coiling stamping part stamping edge material coiling tape

A material guide device and technology for stamping parts, which is applied in the field of material guide devices for stamping edge material coiling of stamping parts, can solve the problems of the punching machine not being able to work continuously, the edge of the material belt shifting, and increasing equipment costs. The configuration of the coiler, the effect of avoiding the movement of the slide plate and improving the working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

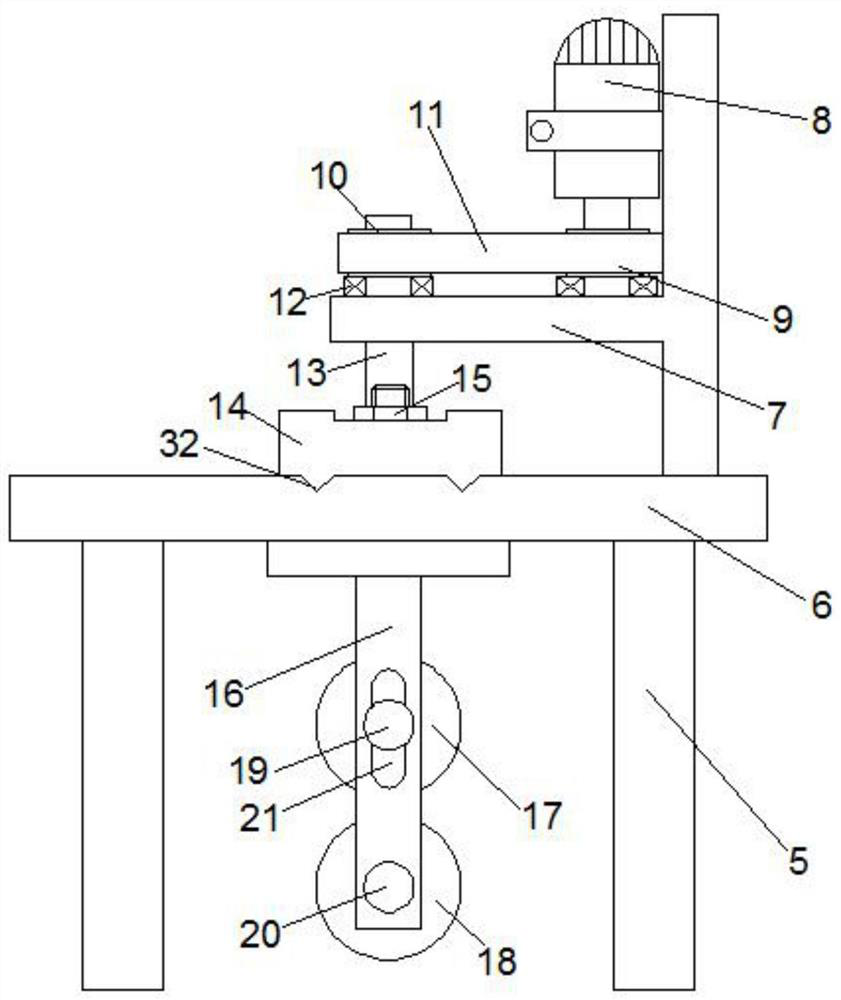

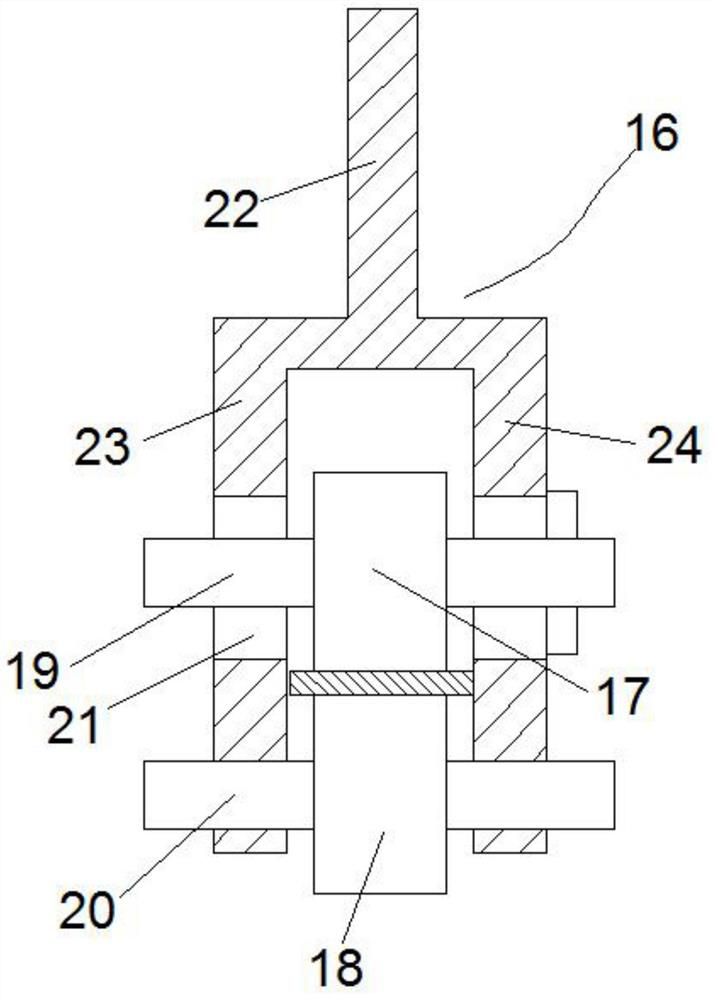

[0029] In a preferred embodiment, the drive device includes a motor 8 and a cam 26 connected to the motor 8, a slide seat 27 is provided at the end of the guide slide 14, and a housing hole 34 for accommodating the cam 26 is provided in the slide seat 27 In this embodiment, the sliding seat 27 is provided with a chute I31, and the end of the guide slide 14 is provided with a pin shaft 30 sliding along the chute I31, and the motor drives the cam 26 to rotate, so that the sliding seat 27 deflects and moves along the cam 26 , under the action of the chute I31 and the pin shaft 30, the material guide slide 14 is moved back and forth along the slide rail, this structure is conducive to waste coiling, and avoids the side material band from forming piles on the waste roll.

[0030]In a preferred embodiment, the accommodating hole 34 is horizontally arranged in the sliding seat 27, and the accommodating hole 34 is provided with a first circular arc inner wall in contact with the distal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com