Compaction mechanical equipment for garbage recycling based on waste filling

A technology for mechanical equipment and garbage, applied in the field of compaction machinery and equipment for garbage recycling, can solve the problems of occupying space garbage, reducing garbage recycling efficiency, etc., and achieve the effect of improving compaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

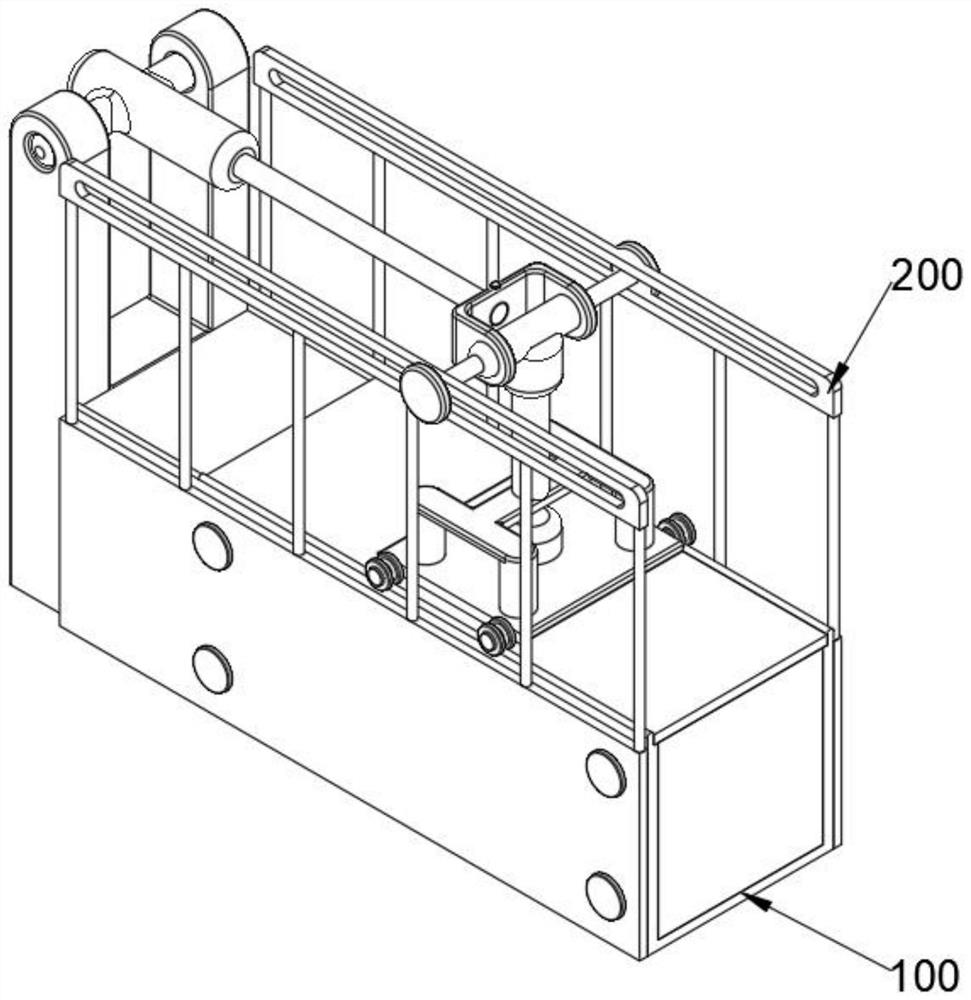

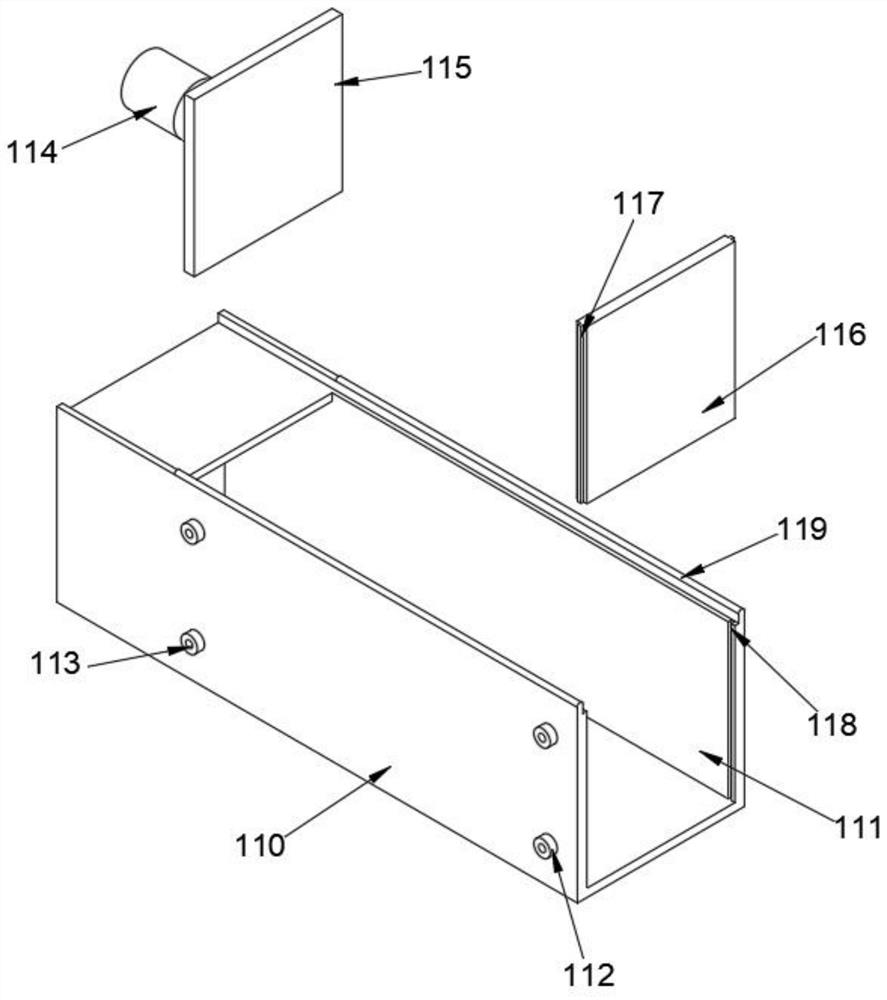

[0043] See Figure 1 - Figure 10As shown, the present embodiment is an object of the present embodiment, providing a waste-filled garbage recovery compaction mechanical apparatus, including garbage storage material for filling waste waste, including a compaction box 110, compromise in the compaction box 110 The press-of-compact box 110 is provided, and the compaction box 110 is connected to the extruder 200 for comparing the waste waste, at least the extruder 200 includes:

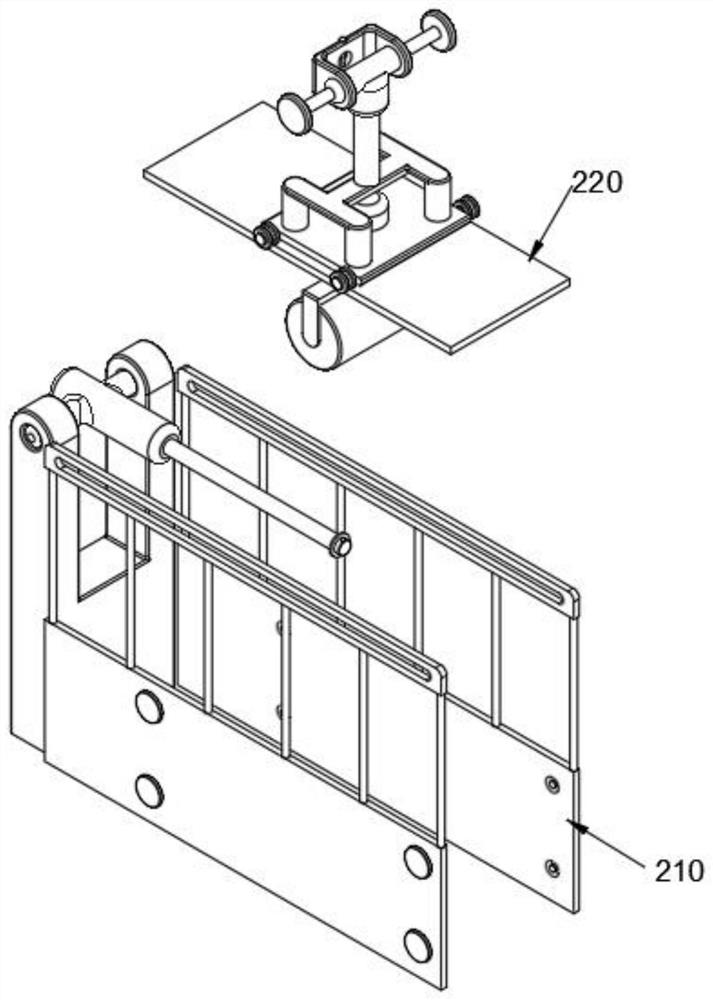

[0044] The mounting body 210, the mounting body 210 includes a fixing body 211 connected to the compaction case 110, the fixing body 211 includes a connecting plate 213, the connecting plate 213 is attached to the outer wall of the compaction case 110, and a plurality of supports are provided at the top of the connecting plate 213. The rod 214, the support rod 214 is connected to a second connection body 215;

[0045] Pressographic solid 220, the pressure solid 220 includes a top bit shifting 221 coupled to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com