Injection mold male mold pitched roof structure capable of being rapidly disassembled and assembled

The technology of injection mold and inclined top is applied in the field of inclined top structure of male mold of injection mold, which can solve the problems of increasing the installation difficulty of male mold core and public template, slow installation of male mold core and public template, affecting the progress of mold disassembly and assembly, etc. To achieve the effect of easy mold repair and maintenance, reduction of labor costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

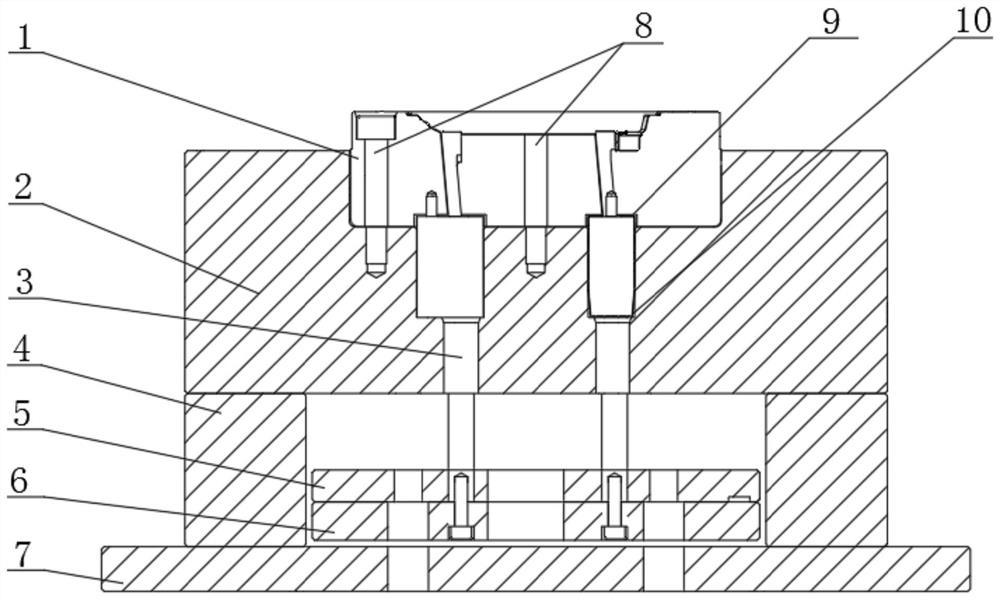

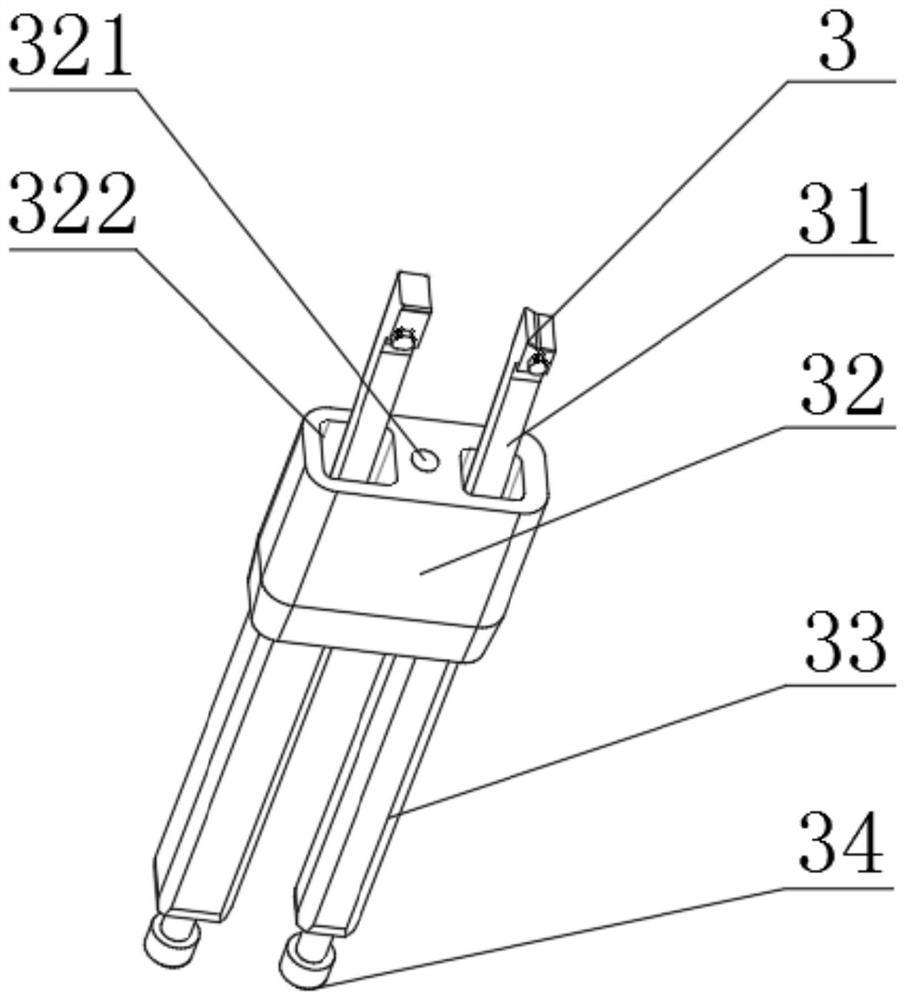

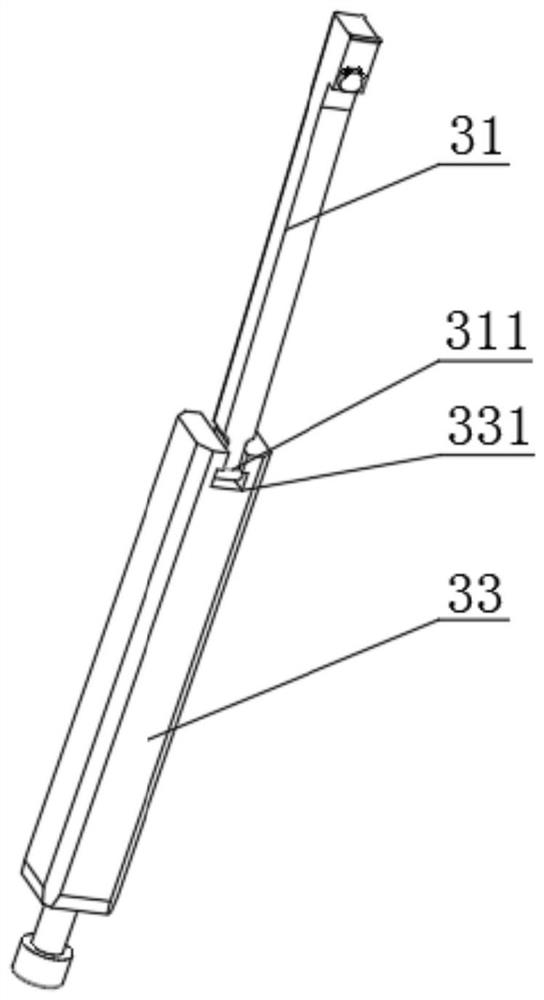

[0023] Such as Figure 1-3 As shown in the figure, a quick disassembly and assembly inclined top structure of the injection mold male mold includes a male mold core 1 and a male template 2, the male mold core 1 is fixed on the male template 2, and the lower part of the male template 2 is sequentially downward An upper ejector plate 5, a lower ejector plate 6, and a lower fixed plate 7 are provided, and the lower fixed plate 7 is provided with two supporting male templates 2 and located on both sides of the upper ejector plate 5 and the lower ejector plate 6. Mold foot 4, a slanted roof structure 3 is provided between the male mold core 1 and the male template 2, and the slanted roof structure 3 includes a slanted roof 31, a slanted roof positioning block 32, a slanted roof seat 33, and a slanted roof seat fastening Screw 34, the inclined top 31 is installed on the male mold core 1, the lower end of the inclined top 31 is clamped with the upper end of the inclined top seat 33, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com