Copper-clad plate and preparation method thereof

A technology of copper clad laminate and copper foil, which is applied in chemical instruments and methods, other household appliances, synthetic resin layered products, etc., can solve the problems of high cost, achieve high yield, easy control, and reduce the width of rolls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

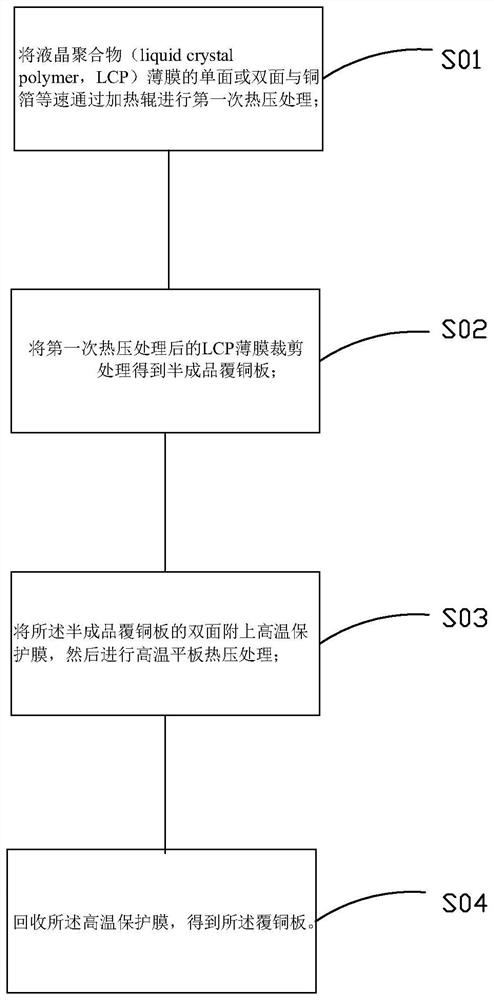

[0029] Embodiments of the present invention provide a method for preparing a copper clad laminate, such as figure 1 Shown include the following steps:

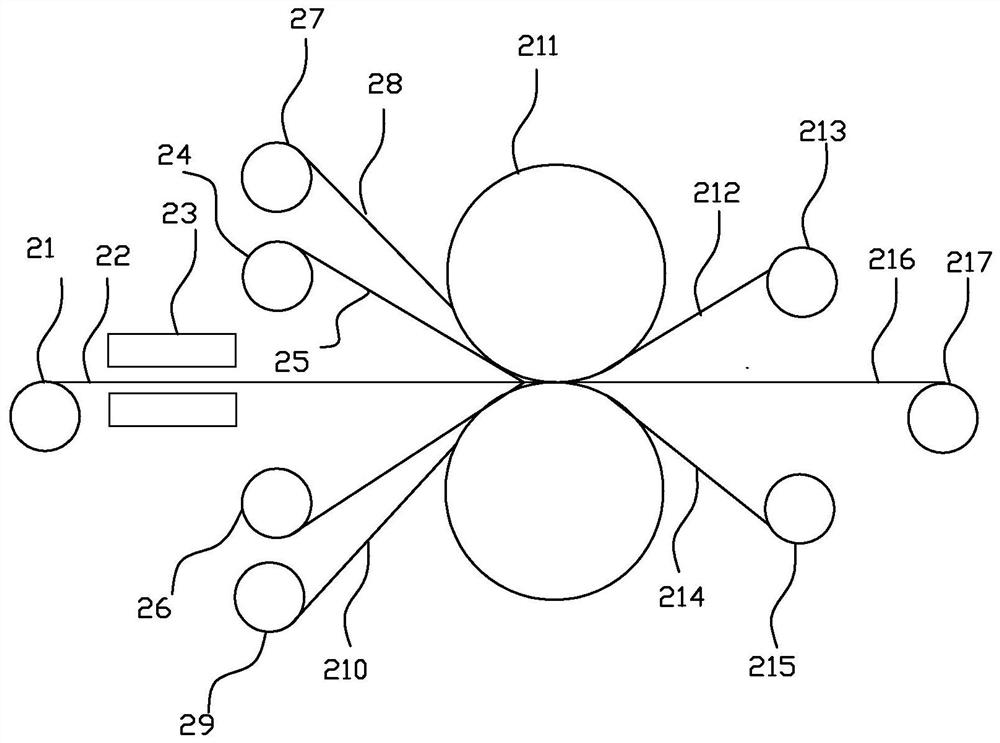

[0030] S01: pass one side or both sides of the liquid crystal polymer (LCP) film and the copper foil through the heating roller at the same speed for the first heat press treatment;

[0031] S02: Attach a high-temperature protective film to both sides of the semi-finished copper-clad laminate, and then perform high-temperature flat-plate hot-pressing treatment;

[0032] S03: Recover the high temperature protective film to obtain the copper clad laminate.

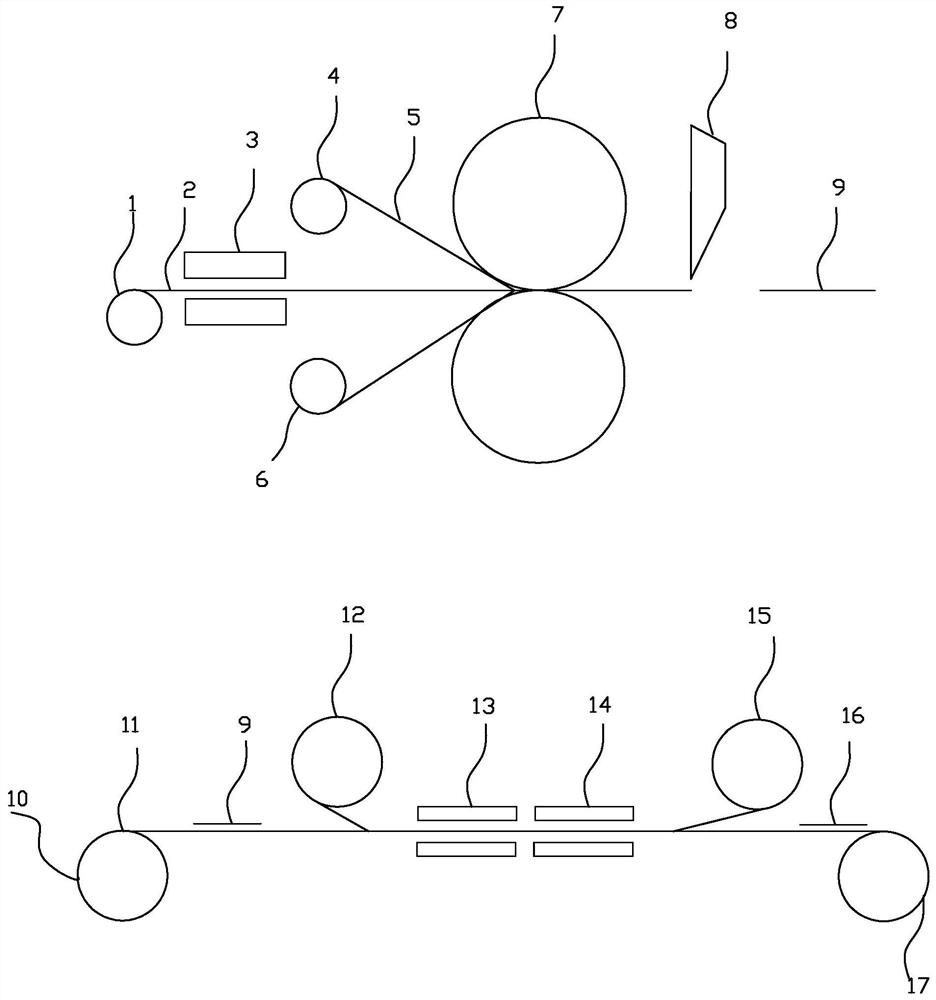

[0033] In a preferred embodiment, the first heat and pressure treatment also includes a preheat treatment of the LCP film. Before the hot pressing treatment, the LCP film can be preheated and softened to facilitate the subsequent hot pressing treatment.

[0034] In a further preferred embodiment, the temperature of the preheating treatment is 100-150°C. Heating and soft...

Embodiment 1-9

[0051] The LCP film with a thickness of 100 μm is sent to the preheating device for preheating treatment through the conveying device, and then the first hot-pressing treatment is performed with the ED copper foil with a thickness of 18 μm and a roughness of 1.3 μm, and then cut to obtain a semi-finished copper clad laminate.

[0052] Cover the semi-finished copper-clad laminate with a protective film, wherein the protective film described in the embodiment 1-2 adopts aluminum foil; embodiment 3-4 adopts copper foil; embodiment 5-7 adopts PI; embodiment 8-9 adopts PTFE; and then proceed sequentially Low-temperature hot-pressing treatment and high-temperature hot-pressing treatment; finally, the protective film is recovered to obtain the copper clad laminates of each embodiment. Each of the above process conditions corresponds to that in Table 1.

[0053] The peeling force and thickness uniformity of the copper clad laminates in each embodiment were tested to obtain the data in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap