Spring seat packing machine

A spring seat, packaging machine technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of easy fatigue of workers, weighing errors, time-consuming and laborious, and achieve the effect of improving inspection efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

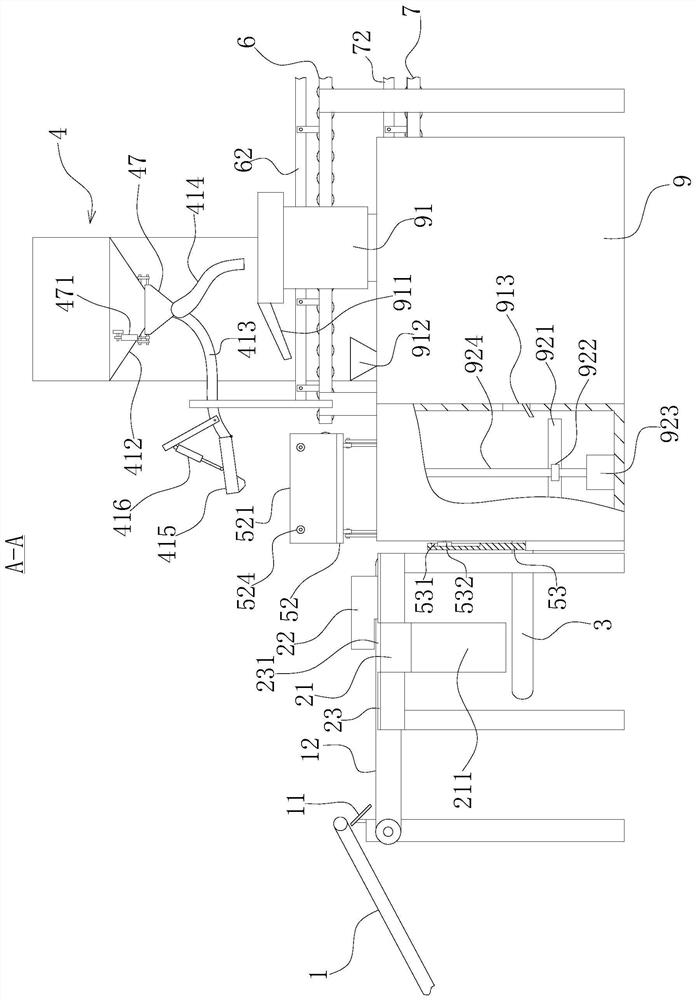

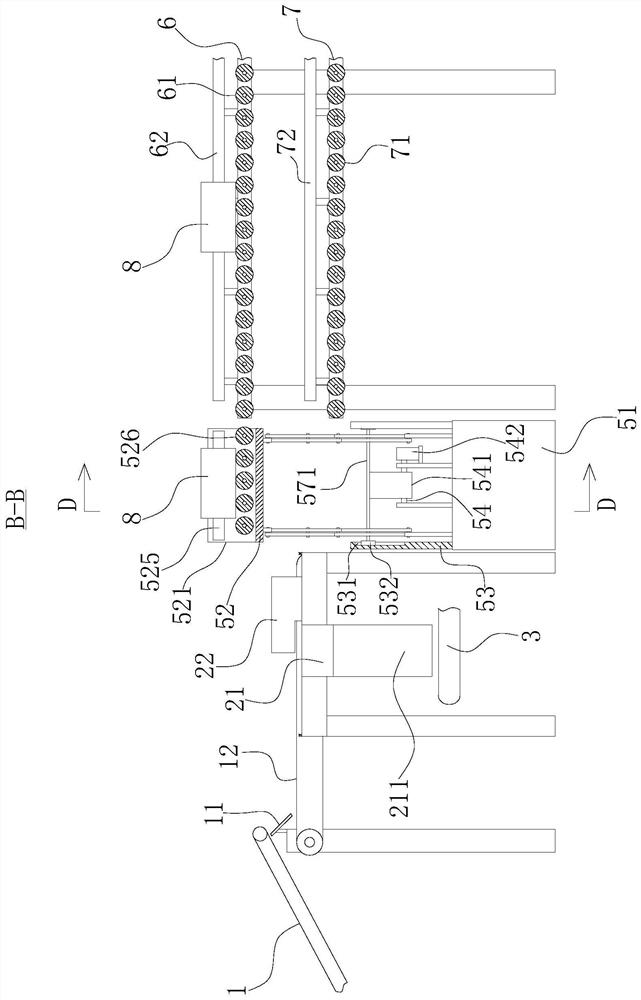

[0058] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

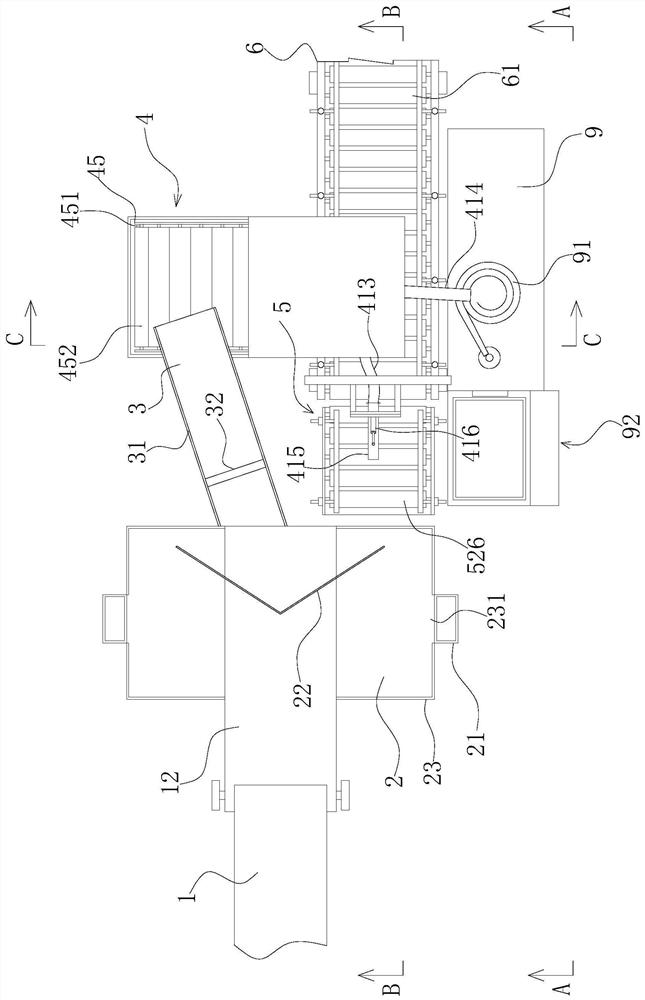

[0059] Such as Figures 1 to 7 As shown, a spring seat packaging machine includes a first conveyor belt 1, a second conveyor belt 12, two operating tables 2, a material guide plate 22, a weighing machine 5, a conveying mechanism, a feeding mechanism and a discharging mechanism.

[0060] The second conveyor belt 12 is arranged horizontally.

[0061] The first conveyor belt 1 is obliquely arranged on the left side of the second conveyor belt 12, and the right end of the first conveyor belt 1 is directly above the left end of the second conveyor belt 12. Preferably, the first conveyor belt 1 and the second conveyor belt 12 The length direction is on a straight line.

[0062] Preferably, a sloping plate 11 is provided obliqu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap