Closestool and one-way valve for jet hole thereof

A spray hole and one-way valve technology, applied in the field of sanitary ware, can solve the problems of affecting the safety of use, unqualified dilution rate, and the basin is easily polluted by dirt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

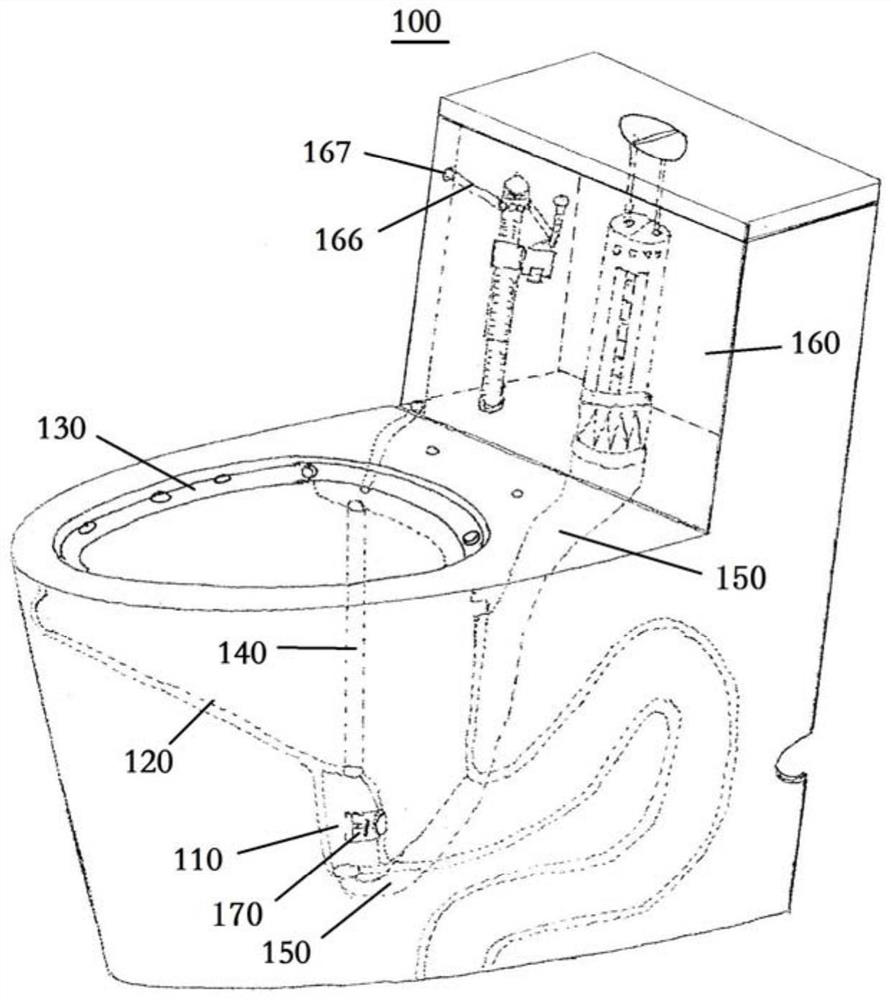

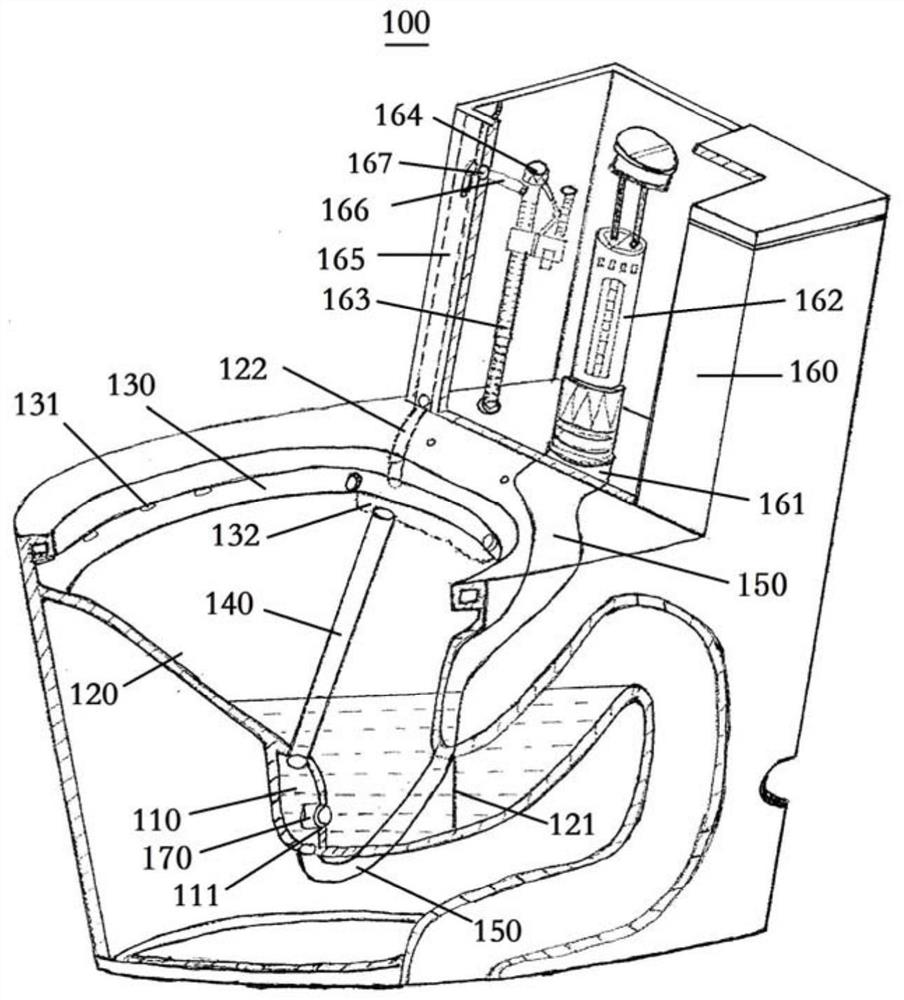

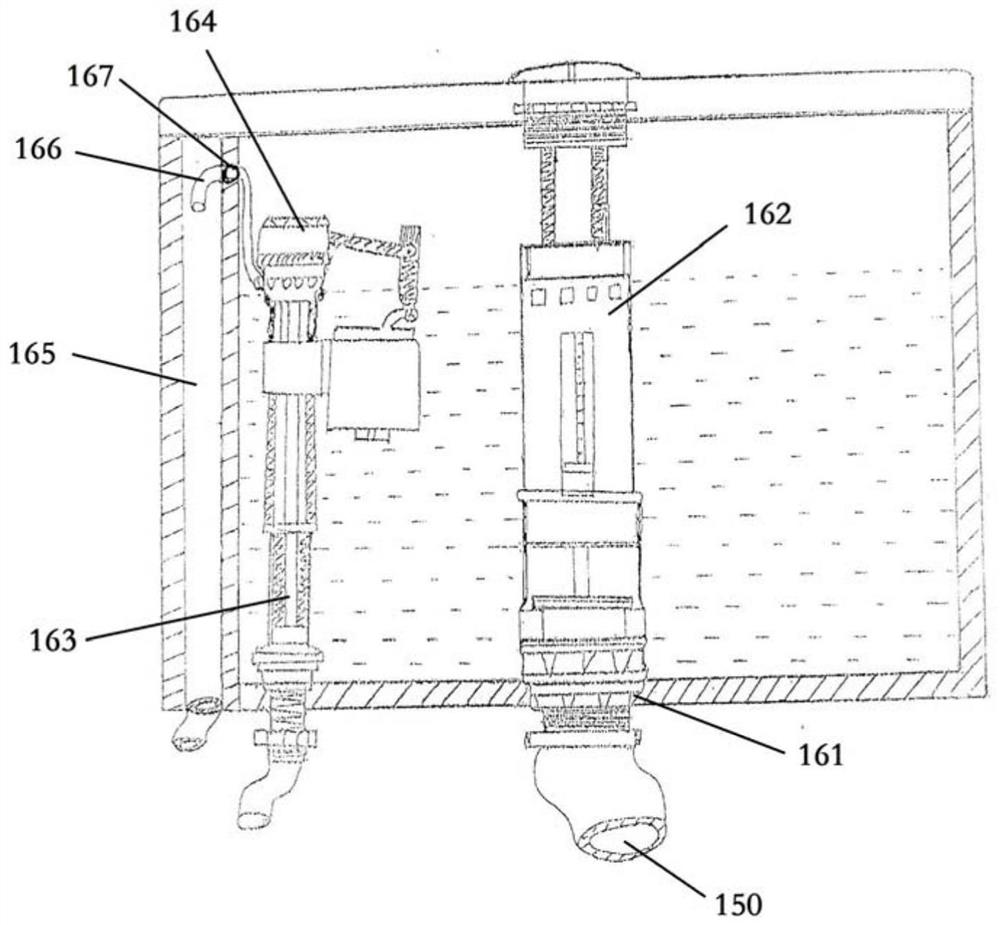

[0059] see Figure 1-Figure 2 , the embodiment of the present application provides a toilet 100 , including a basin body 120 , a water guiding ring 130 , a scrubbing pipe 140 , a drain pipe 150 and a water tank 160 . The toilet 100 has an injection chamber 110 located below the water storage surface of the basin body 120 , and the drain pipe 150 communicates with the outlet 161 of the water tank 160 and the injection chamber 110 .

[0060]The injection chamber 110 is provided with an injection hole 111 communicating with the inner cavity of the basin body 120 , and the injection hole 111 is connected with a one-way valve 170 configured to allow water to flow into the basin body 120 unidirectionally. The injection hole 111 is used to unidirectionally spray the water flow in the injection chamber 110 into the inner cavity of the basin body 120. Further, the injection hole 111 is set opposite to the sewage outlet 121 of the basin body 120, so that the storage of the basin body 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com