Prefabricated buckle suspended ceiling mounting structure

An installation structure and prefabricated technology, applied in ceilings, building components, building structures, etc., can solve the problems of increasing project maintenance costs, increasing the probability of material damage, and large repetitive labor input, so as to reduce labor and material costs and improve Decoration efficiency, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

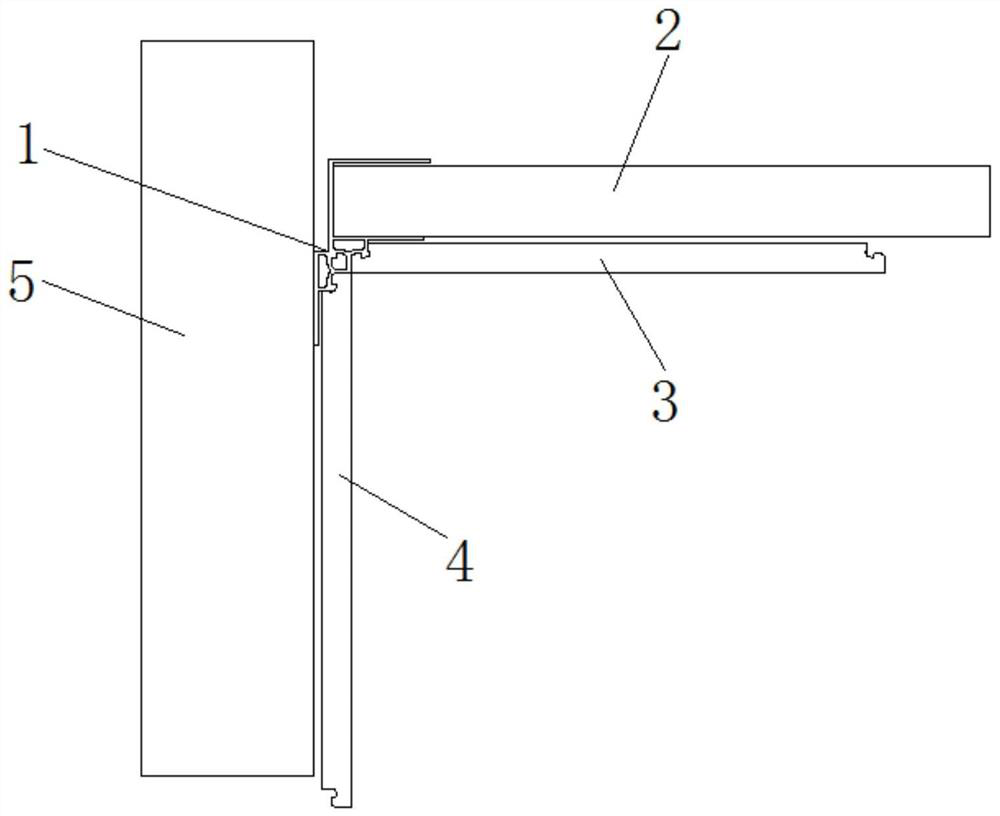

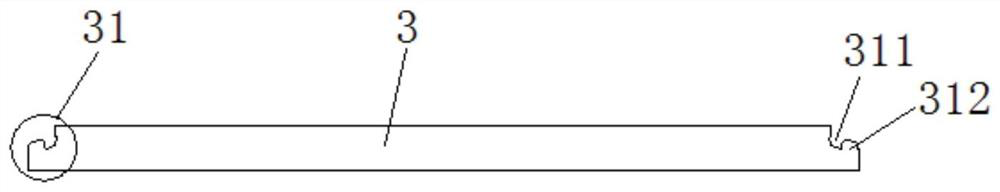

[0031] see Figure 1 to Figure 4 , the figure shows a prefabricated buckle ceiling installation structure provided by Embodiment 1 of the present invention, including: a snap-in piece 1, which includes a first snap-in portion 11 and a second snap-in portion arranged sequentially from top to bottom part 12 and the third clamping part 13; the ceiling keel 2, whose end is clamped with the first clamping part 11; the ceiling board 3, which is located below the ceiling joist 2, and the two ends of the ceiling board 3 are symmetrically arranged The first buckle 31, one side of the ceiling board 3 is engaged with the second buckle 12 through the first buckle 31; the wallboard 4 is arranged on the side wall 5, and the two ends of the wallboard 4 are provided with second Buckle 41 , the top of the wall panel 4 is engaged with the third buckle 13 through the second buckle 41 .

[0032] An assembled buckle ceiling installation structure provided in this embodiment mainly includes a clam...

Embodiment 2

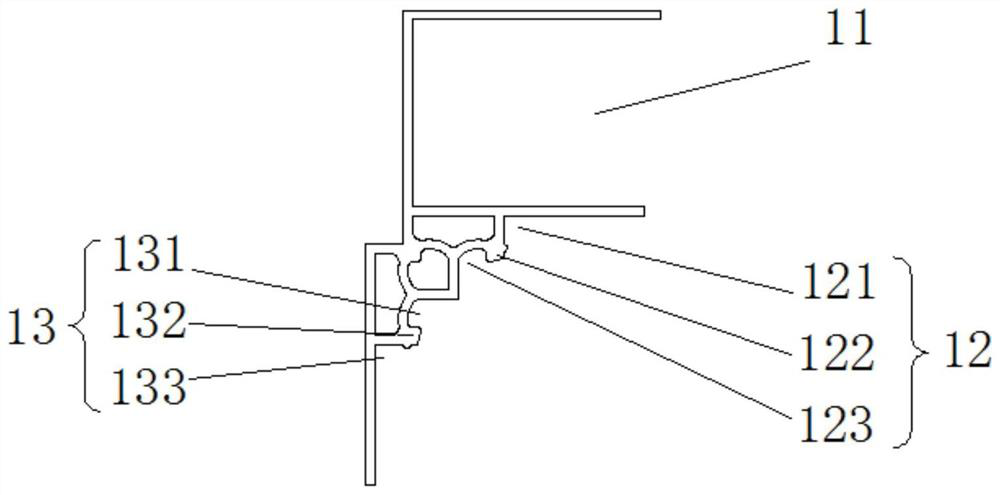

[0038] see figure 2 , the figure shows a prefabricated buckle ceiling installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first snap The connecting portion 11 is a locking groove; the opening of the first locking portion 11 is set toward the outside of the side wall 5; the second locking portion 12 includes a first locking groove 121, a first locking protrusion 122 and a The second locking slot 123 ; the third locking portion 13 includes a third locking slot 131 , a second locking protrusion 132 and a fourth locking slot 133 arranged in sequence from top to bottom. Through the setting of the above structure and the setting of the clamping groove, the end of the ceiling board 2 can be directly inserted and positioned, and the connection strength and positioning effect can be improved; both the second clamping part 12 and th...

Embodiment 3

[0040] see figure 2 , the figure shows a prefabricated buckle ceiling installation structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first snap The structure of the groove 121 is consistent with that of the fourth locking groove 133 ; the structure of the second locking groove 123 is consistent with that of the third locking groove 131 ; the structure of the first locking protrusion 122 is consistent with that of the second locking protrusion 132 . Through the arrangement of the above structure, a symmetrical structure is formed, which is not only beautiful, but also more convenient in production and simplifies the process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com