Ceramic tile cement smearing device for building decoration

A ceramic tile and cement technology, applied in the direction of construction and building structure, can solve the problems of uneven application, low work efficiency, large waste of cement, etc., and achieve the effect of convenient use and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

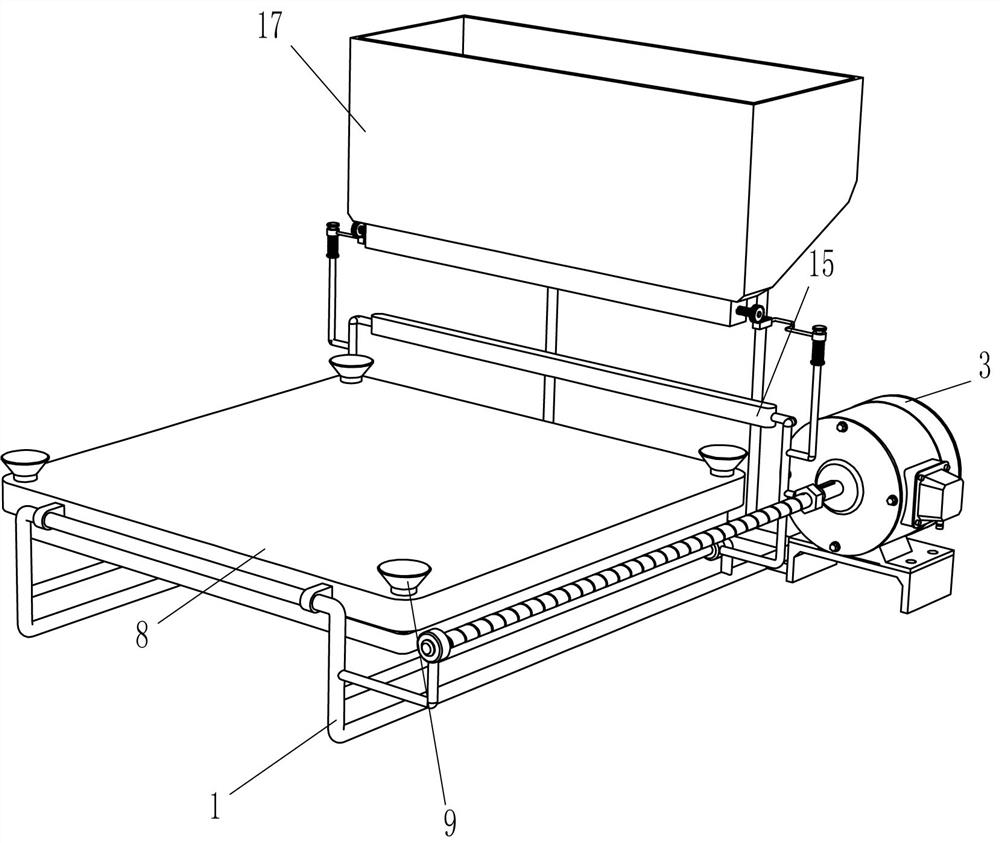

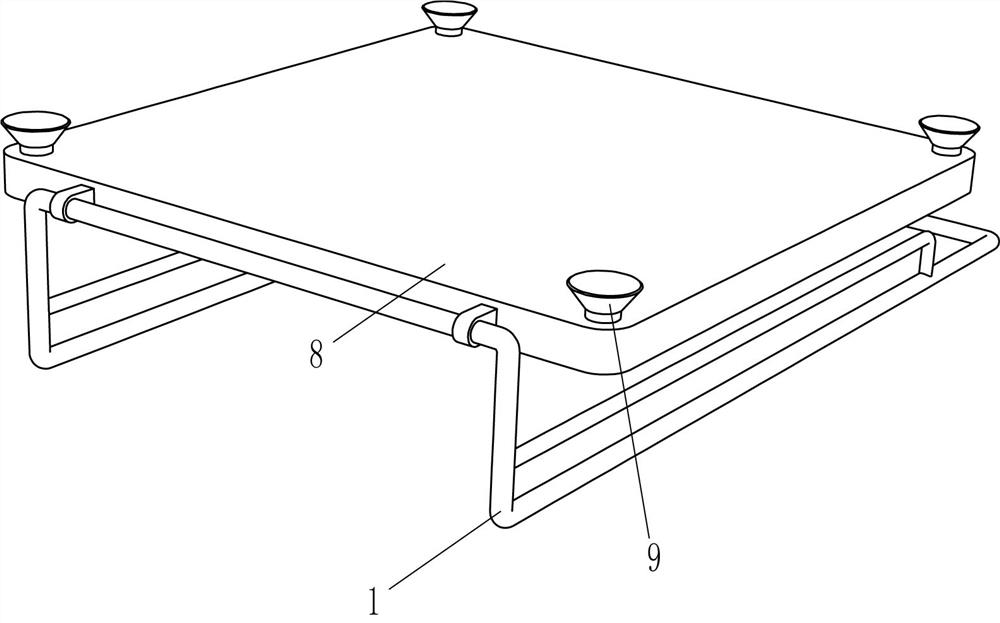

[0021] A kind of ceramic tile cement application device for building decoration, such as Figure 1-6 As shown, it includes a support frame 1, a power assembly, a placement assembly, an air release assembly, and a caressing plate 15. The support frame 1 is provided with a power assembly that provides power by rotating, and the support frame 1 is provided with a placement assembly, placed The assembly is provided with a deflation assembly that deflates by sliding, and a smoothing plate 15 is welded on the power assembly.

[0022] Such as figure 1 , 2 As shown in and 5, the power assembly includes a placement seat 2, a geared motor 3, a right-angle rod 4, a screw mandrel 5, a nut 6 and a connecting rod 7, and the rear right part of the support frame 1 is welded with a placement seat 2, and the placement seat 2 passes through The bolt is fixedly connected with a deceleration motor 3, and the right side of the support frame 1 is symmetrically provided with two right-angled rods 4...

Embodiment 2

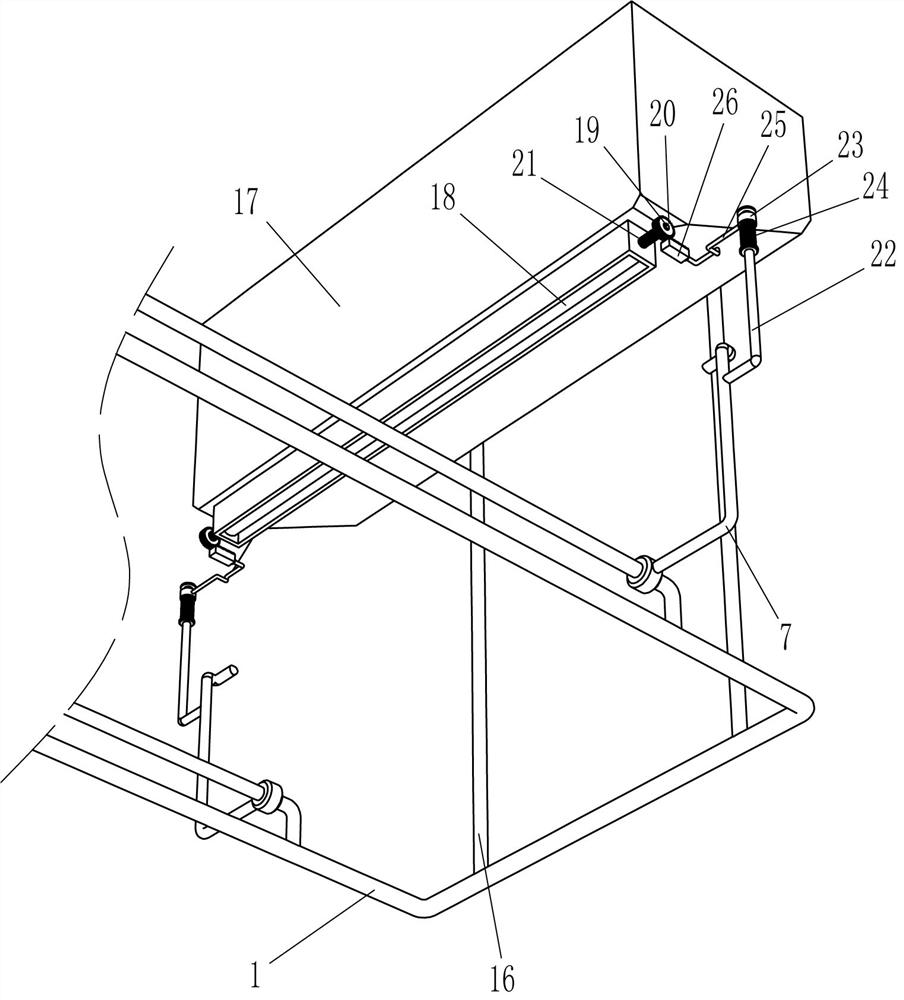

[0030] On the basis of Example 1, such as figure 1 with 6 Shown, also include support rod 16, hopper 17, semi-cylindrical frame 18, rotating rod 19, one-way gear 20, torsion spring 21, guide rod 22, guide sleeve 23, second spring 24, special-shaped rod 25 and tooth Bar 26, bracing frame 1 back side is welded with support bar 16 symmetrically left and right, is welded with hopper 17 between the tops of support bar 16, and the bottom of hopper 17 is rotatably provided with rotating rod 19, and rotating rod 19 is provided with semi-cylindrical frame 18, The semi-cylindrical frame 18 is located in the discharge port of the hopper 17, the left and right ends of the rotating rod 19 are connected with a one-way gear 20, a torsion spring 21 is wound between the rotating rod 19 and the hopper 17, and a guide rod is welded on the outside of the connecting rod 7 22, the guide rod 22 is equipped with a guide sleeve 23 slidingly, the second spring 24 is wound between the bottom of the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com