Suspension bridge tunnel anchor chamber vault secondary lining construction equipment and method

A technology of construction equipment and anchor room, which is applied in the direction of tunnel lining, tunnel, mining equipment, etc., can solve the instability of the support of the full hall support and the arc-shaped vault of the front anchor room, the deflection of the concrete pouring force, and the construction Process control is difficult and other problems, to achieve good construction economic benefits, solve the problem of insufficient construction safety and reliability, and achieve the effect of safe and efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

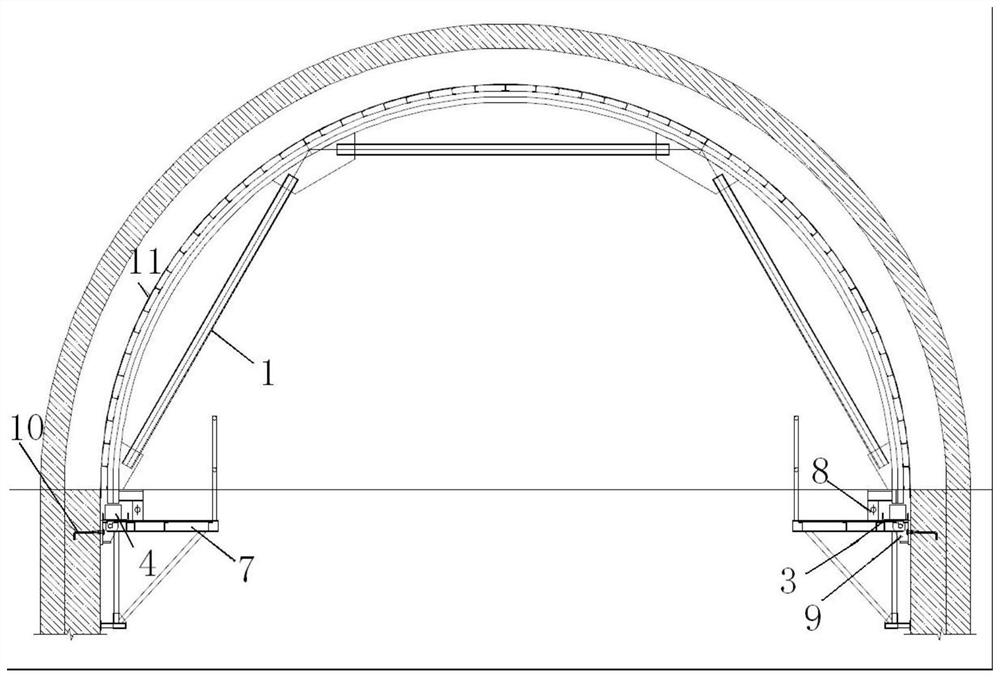

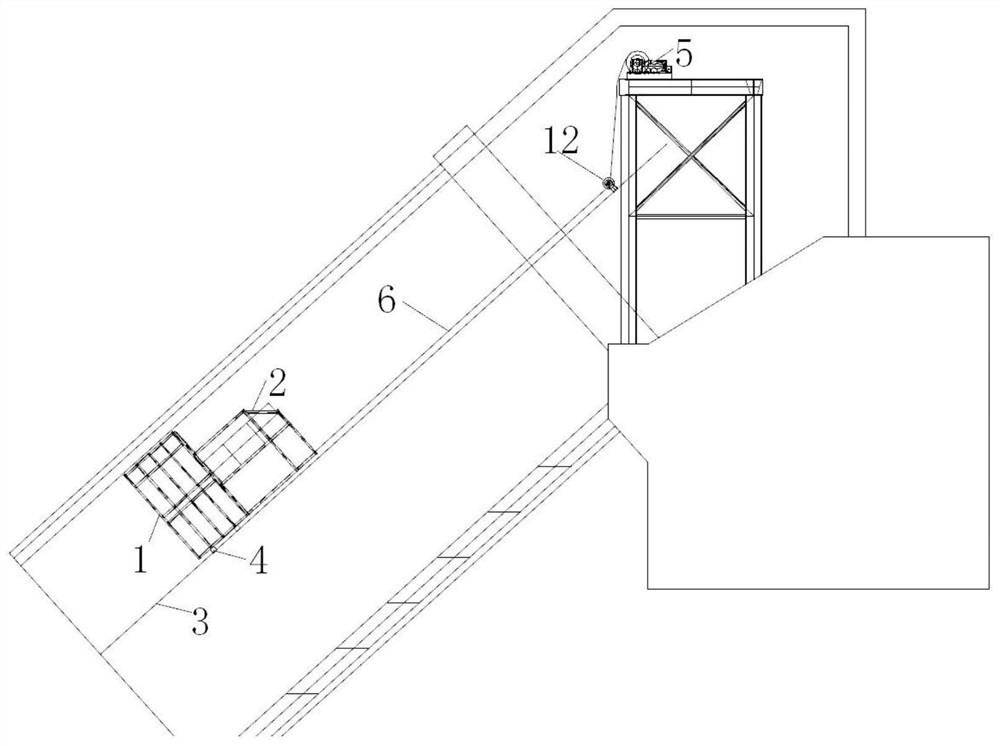

[0025] Such as figure 1 and figure 2 As shown, a construction equipment for the second lining of the vault of the anchor chamber of the suspension bridge tunnel, including a trolley 1, a stand 2, a moving track 3, a traction unit, and a construction formwork 11, the construction formwork 11 is connected to the outside of the trolley 1, The trolley 1, the platform 2 and the traction unit are connected in sequence, and the trolley 1 and the platform 2 are both connected on the moving track 3.

[0026] Pull the platform 2 to the position of the pre-construction vault through the traction unit, install the waterproof board and steel bars, and pull the trolley 1 to this position after completion. After the trolley 1 is in place, lift the trolley 1 and the construction formwork 11 to the top The installation position of the construction formwork, adjust the construction formwork 11, confirm that it is consistent with the design position, and then use a backing plate to pad the bot...

Embodiment 2

[0028] On the basis of Embodiment 1, the traction unit includes a tractor 5, a traction wire rope 6 steering wheel 12, and the stand 2, the steering wheel 12 and the traction machine 5 are sequentially connected by the traction wire rope 6; the traction machine 5 is a traction hoist Or chain hoists. The tractor 5 is arranged on the portal frame of the tunnel anchor hole or the tunnel anchor hole. The number of the tractor 5 can be adjusted according to the actual situation. Compared with chain hoists, traction hoists have faster traction speed and stable construction; chain hoists have relatively simple equipment, which can be selected according to actual conditions and have strong adaptability.

[0029] The trolley 1 also includes a shifter 4 through which the trolley 1 is connected to the moving track 3 . The shifter 4 is convenient for the trolley 1 to slide on the moving track, reduces friction, saves time and effort, and improves work efficiency.

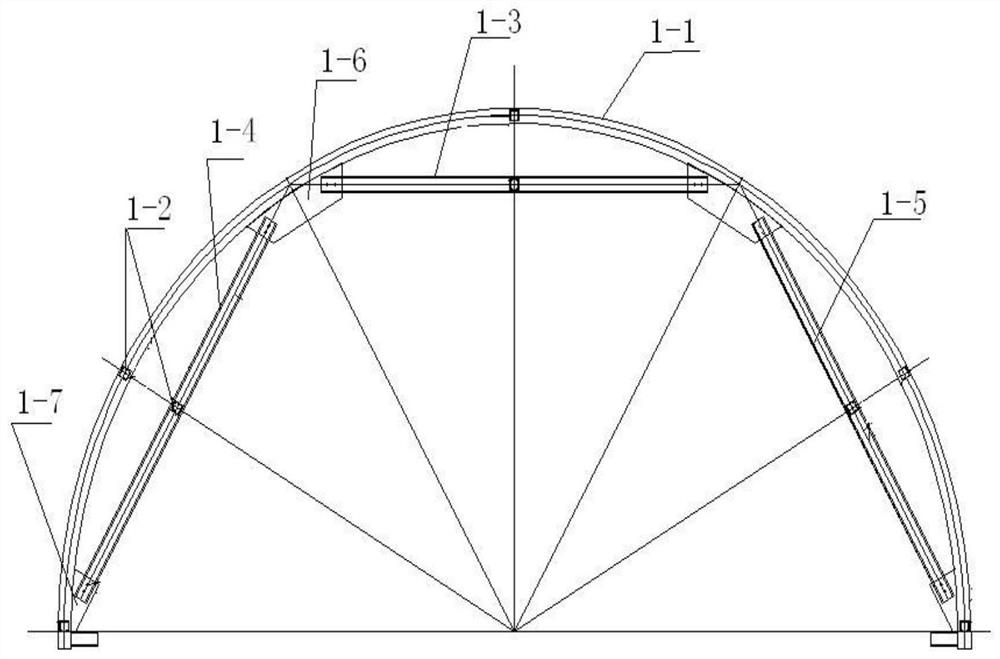

[0030] Such as Figu...

Embodiment 3

[0032] On the basis of Embodiment 2, hangers 7 are also included. The number of hangers 7 is 2 groups and the left and right sides of the 2 groups of hangers 7 are symmetrically distributed on the left side wall and the right side wall of the front anchor room. The axis direction of the front anchor chamber is connected with the moving track 3 . The number of hangers is determined according to the force calculation results of the trolley construction. In this project, there are 6 hangers in 2 groups under the trolley, 3 hangers on each side, symmetrically distributed from left to right; the moving track 3 is a sliding track, and the sliding track adopts The channel steel is made and placed on the hanger 7 of the left side wall and the right side wall of the front anchor room. Ensure that the sliding track and the hanger are all in close contact to facilitate the movement of the trolley.

[0033] Also include a jack 8, the bottom of the jack 8 is connected to the top of the ha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap