Curved surface morphology acquisition and measurement system

A measurement system and topography technology, applied in measurement devices, optical devices, optical testing of flaws/defects, etc., can solve the problems of manual coordination measurement, poor real-time measurement of curved surfaces, and low measurement accuracy, so as to avoid measurement accuracy deviation. Low, the effect of realizing measurement and ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

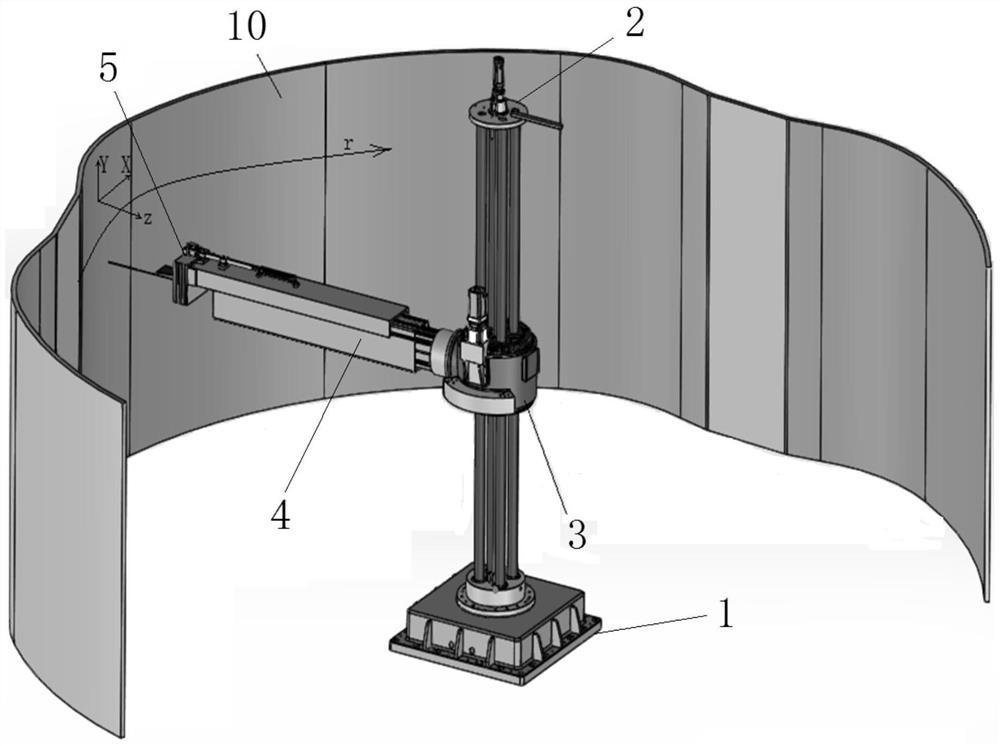

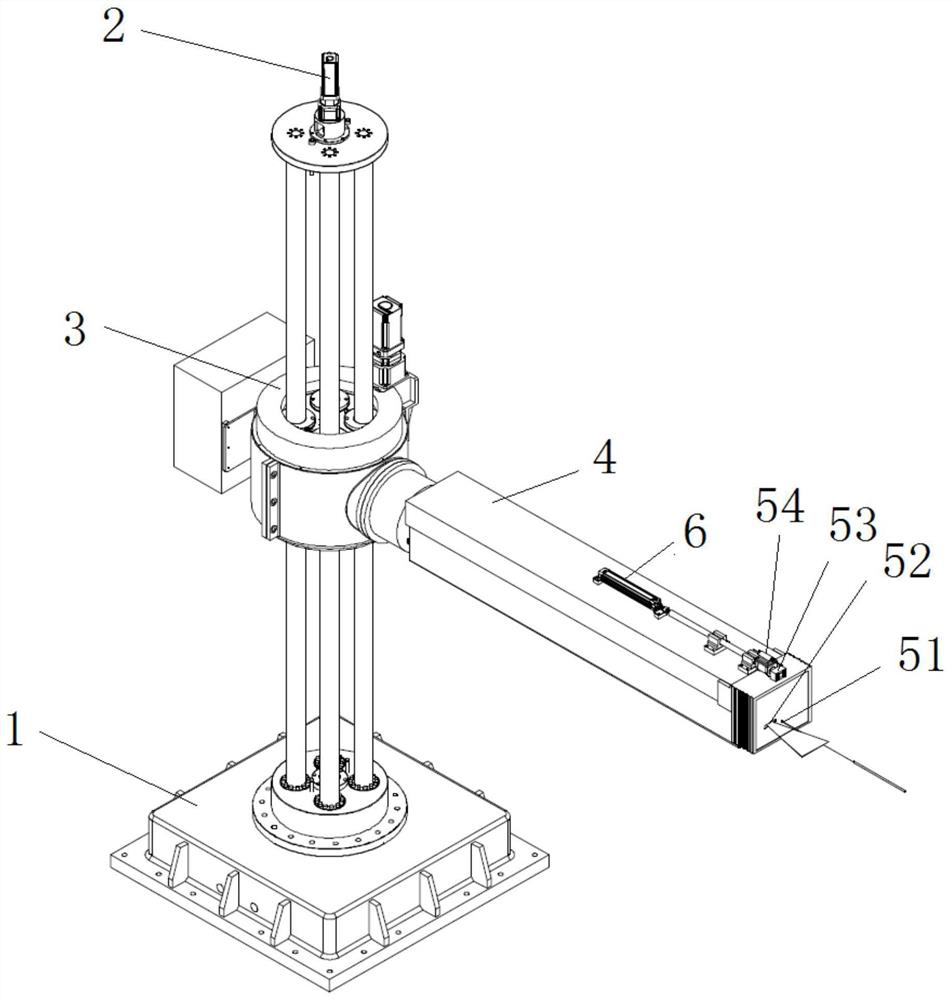

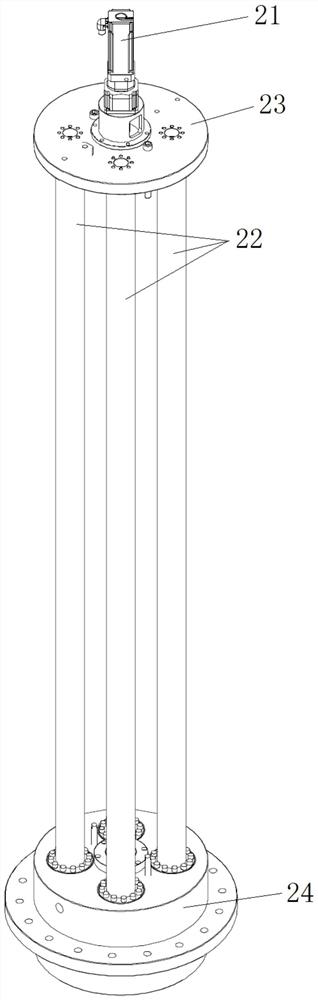

[0031] Such as figure 1 , figure 2 As shown, Embodiment 1 of the present invention provides a curved surface profile acquisition and measurement system, which is referred to as this system hereinafter, which includes a base 1, a lifting drive device 2, a steering seat 3, a telescopic mechanical arm 4, a measurement sensor 5, and a measurement terminal;

[0032] The lifting driving device 2 is installed on the base 1, and the lifting driving device 2 is connected to the steering base 3 and drives the steering base 3 to move up and down. One end of the telescopic mechanical arm 4 is connected to the steering base 3. The base 3 is connected, the measuring sensor 5 is installed at the other end of the telescopic manipulator 4, and the lifting driving device 2, the steering base 3, the telescopic manipulator 4 and the measuring sensor 5 are respectively electrically connected to the measuring terminal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com