Optical fiber connector tension and lens bonding thrust testing tool and application thereof

A fiber optic connector and testing tooling technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of not finding fiber optic connectors, etc., and achieve obvious functions, convenient use, and wide range of use wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

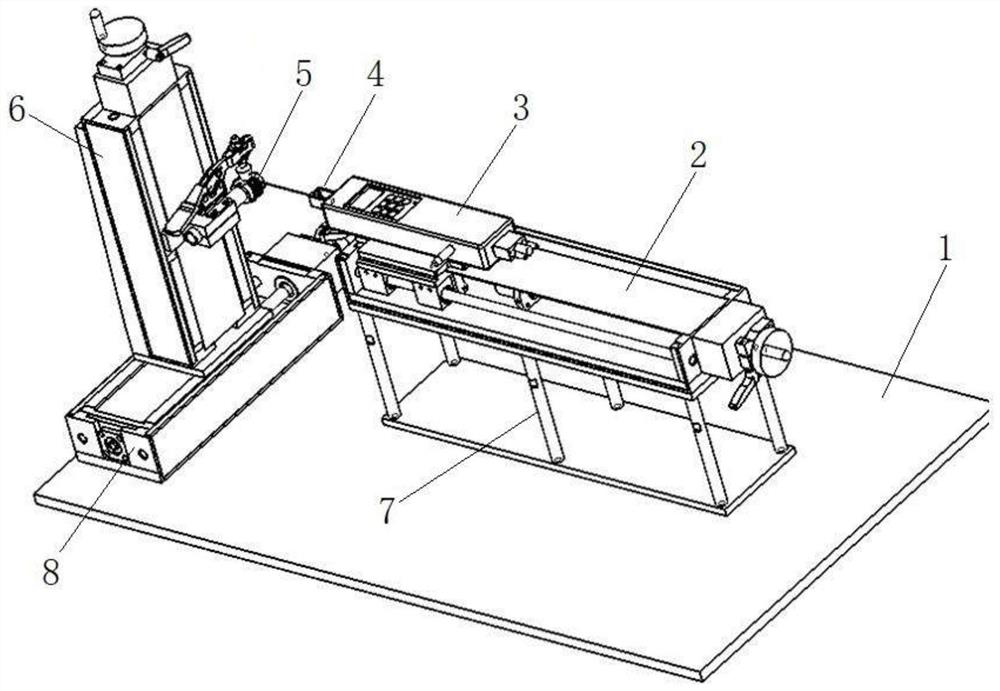

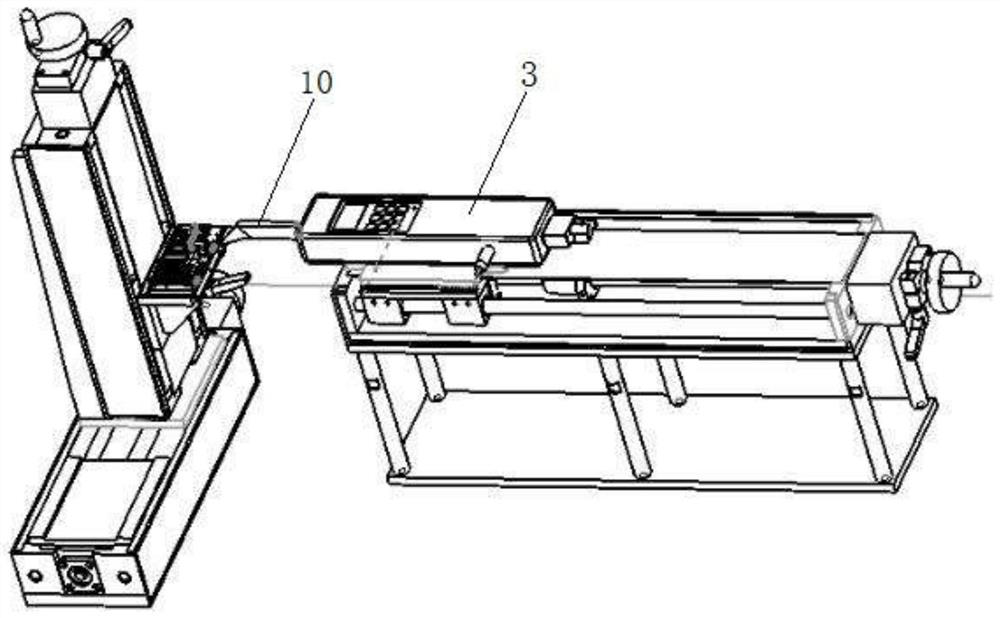

[0049] Such as Figure 1 to Figure 8 As shown, the present embodiment provides a tool for testing optical fiber connector tension and lens bonding thrust, which includes two parts: a translation platform 2 and an elevating platform 6 arranged opposite to the translation platform;

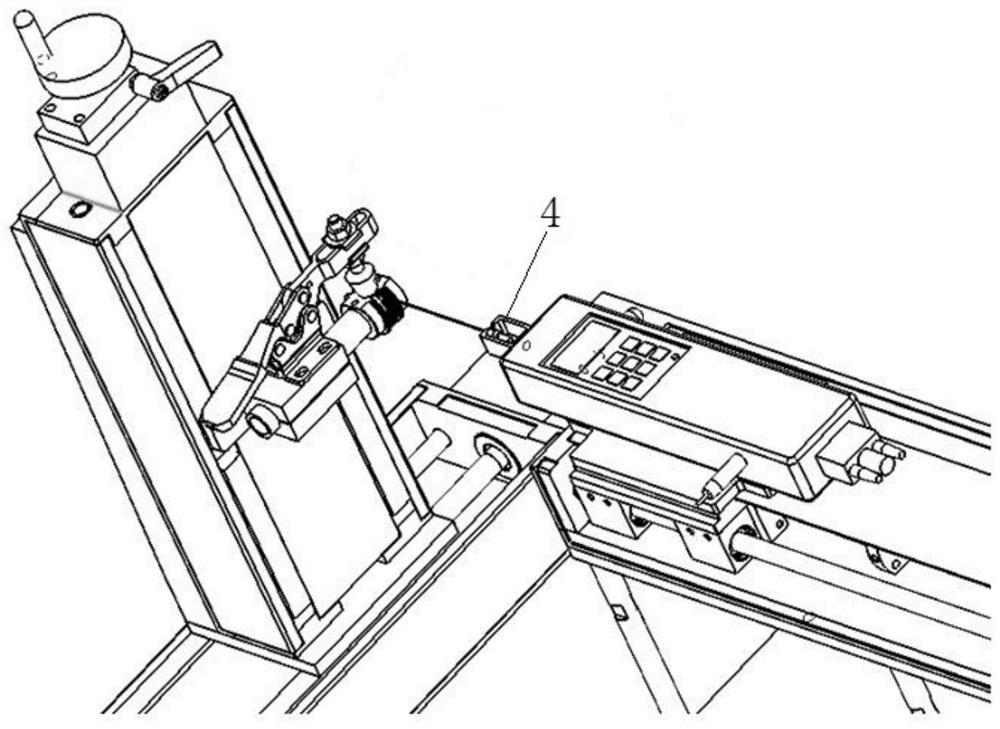

[0050] The displacement table 2 is provided with a sliding device and a push-pull gauge 3, and the sliding device drives the push-pull gauge 3 to generate a displacement, and one end of the push-pull gauge 3 is provided with a fixing fixture 4 or a thrust fixture 10;

[0051] One side of the lifting table 6 is provided with a lifting device, a winding fixture 5 and / or a loading fixture 20, and the winding fixture 5 and / or loading fixture 20 are arranged on the lifting device, and the winding fixture 5 and / or the loading fixture 20 are driven up and down by the lifting device move.

[0052]The technical solution of this embodiment is a multi-purpose machine, and different tests are realized by using...

Embodiment 2

[0059] A kind of optical fiber connector pulling force and lens bonding thrust testing tool, the structure is as described in embodiment 1, and its difference is: fixing fixture 4 comprises a rectangular body, and positioning groove 401 and narrow opening 402 (relatively) are arranged on the body For the wide opening of Example 1). Fixing jigs of this specification can be used to place (fix) cylindrical thin connectors.

Embodiment 3

[0061] A tool for testing optical fiber connector tension and lens bonding thrust, the structure is as described in Embodiment 1, the difference is that: the body of the fixing fixture 4 is also provided with a transverse opening positioning groove 403, and the transverse opening positioning groove 403 is located in the opening 402, and the transverse opening positioning groove 403 runs through the body. Through the laterally opened positioning groove 403 and the positioning groove 401, the special-shaped optical fiber connector can be effectively fixed for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com