Optical radiator

An optical radiation and radiator technology, applied in the field of optical radiators, can solve the problem that the optical radiator cannot meet the application requirements of wide radiation angle and high radiation intensity at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

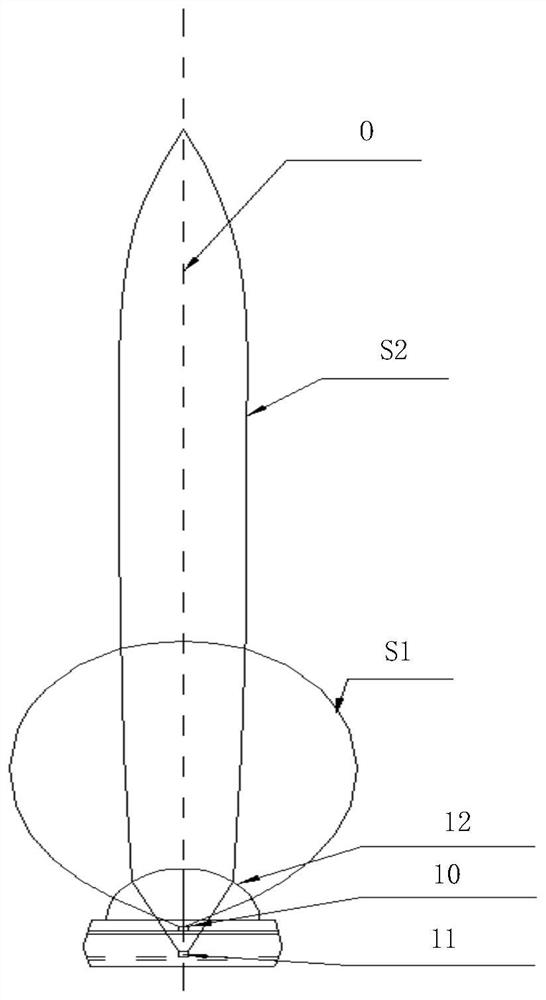

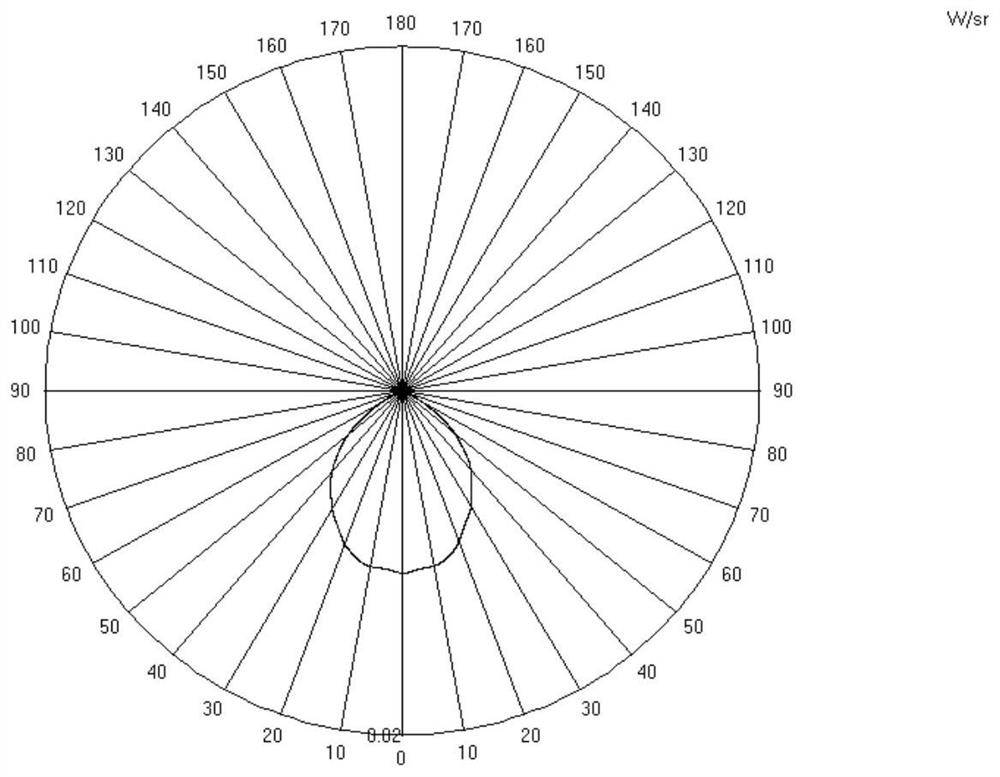

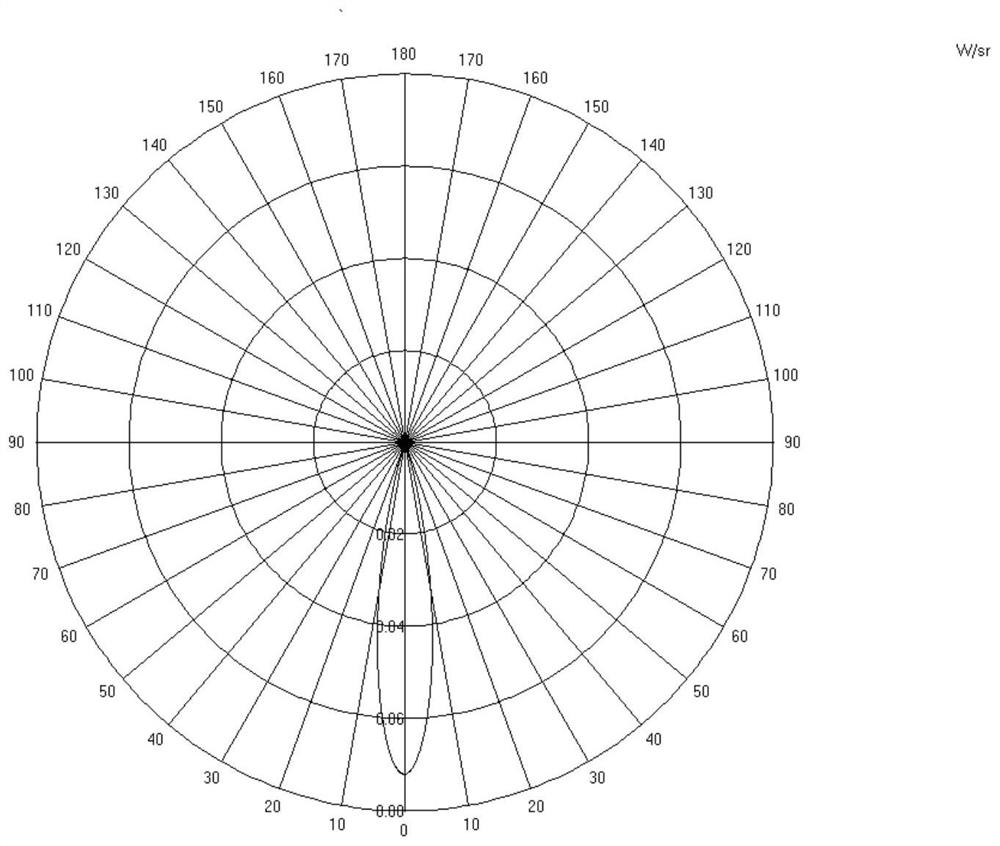

[0034] As in the background art, existing optical radiators cannot meet the application requirements of wide radiation angle and high radiation intensity at the same time. The inventors found that the main reason for this problem is that the light radiator composed of a single light-emitting chip 10, 11 and the convex lens 12, the center position of the light-emitting chip 10 or 11 is usually on the main optical axis O of the convex lens 12 , its peak radiation intensity is also on the main optical axis O of the convex lens 12, the spatial distribution of the radiation is conical S1, S2 and its axis coincides with the main optical axis O of the convex lens 12, as figure 1 Shown is an optical simulation relationship diagram of the radiation intensity and radiation angle of light emitted by a single light-emitting chip 10, 11 and a convex lens 12, figure 2 It is the actual test chart of the radiation intensity and radiation angle of the light emitted by a single light-emitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com