Thermoplastic

A thermoplastic, crystalline technology that is applied in the field of thermoplastics to solve problems such as insufficient storage stability, insufficient dual curing, and poor resistance to cold fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The polyesters (A) of the invention are produced using monomers according to the following table 1:

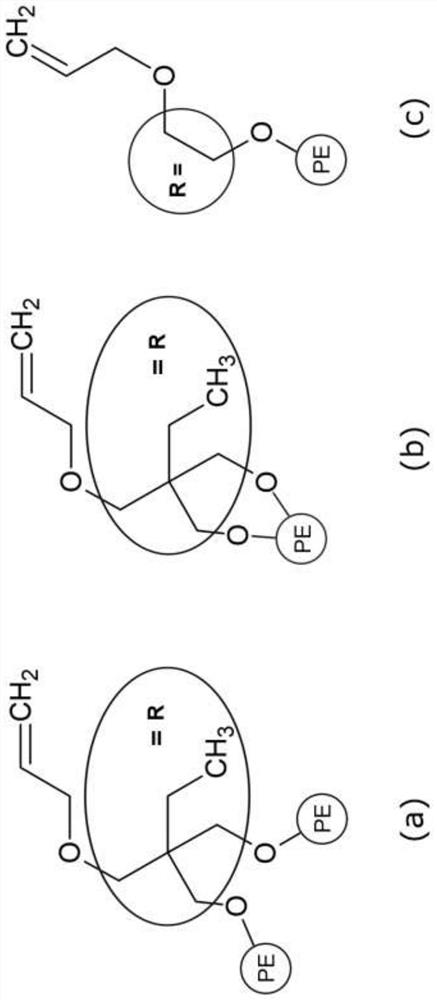

[0072] Polyester (A) with allyl groups in one-step process (preferred embodiment; referred to as "one-step process" in Table 1)

[0073] All monomers and reactants were weighed in the reaction flask. The flask was purged with nitrogen. The mixture was heated up to 40 °C and MIBK was added using a dropping funnel. The mixture was heated to 210°C to 230°C. The water of reaction was collected and compared to the theoretical amount calculated from the resin formulation. When the reaction was complete and the resin was clear, vacuum was applied (500+ / -50mbar). After 10 minutes the pressure dropped to 300+ / -50mbar. All in all, the total time the vacuum was applied was 5 hours. Finally, the resin was drained onto an aluminum plate and allowed to cool overnight.

[0074] Polyester (A) having an allyl group in a two-step process (referred to as "two-step process" in T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com