Novel wheat stubble crusher

A pulverizer and wheat stubble technology, which is applied to agricultural machinery and tools, shovels, plows, etc., can solve the problems of labor-consuming, time-consuming and labor-intensive, and the inability to effectively crush wheat stubble for multiple times of rotary tillage, so as to reduce energy loss, improve operating efficiency, and The effect of the rotary cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

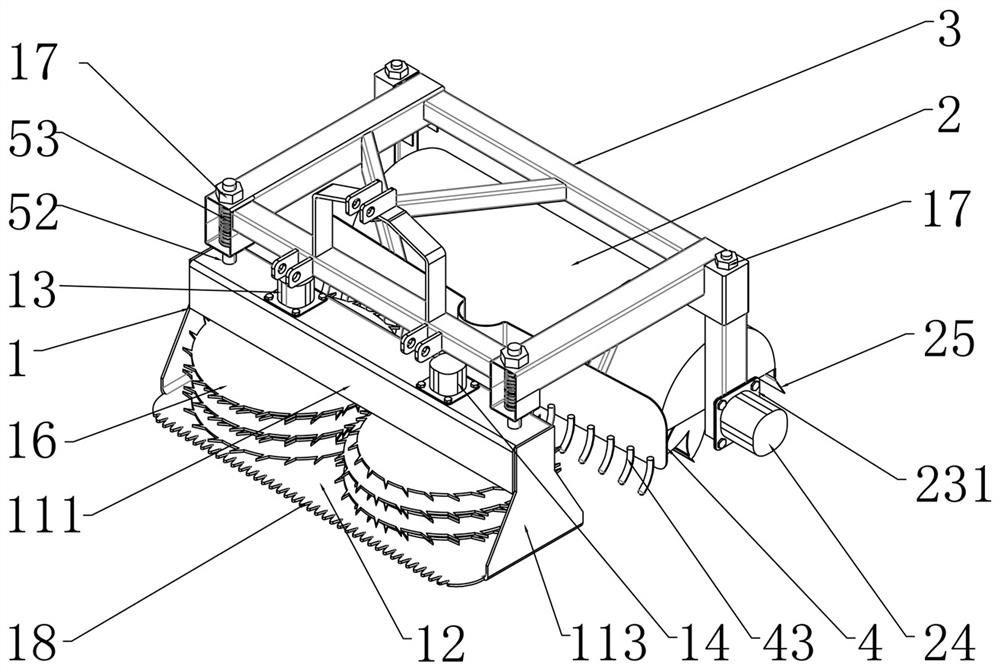

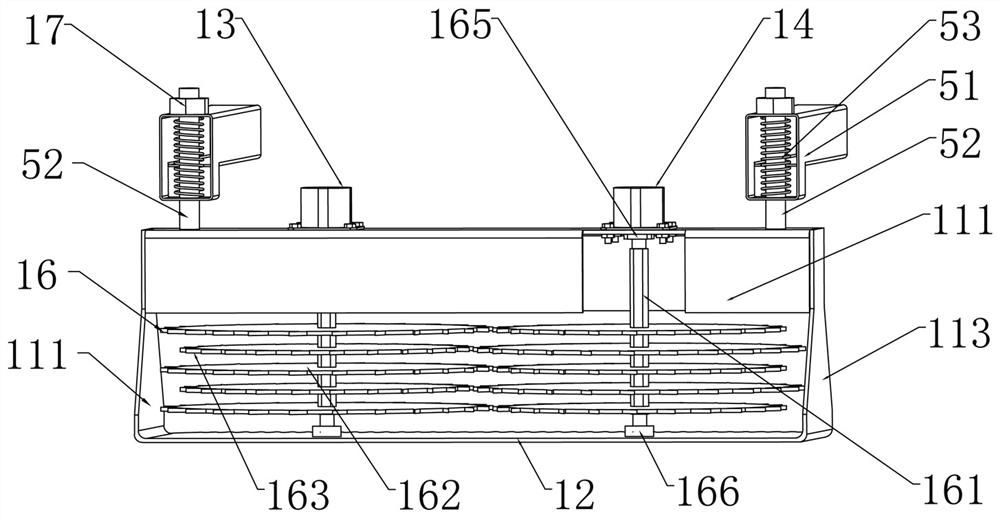

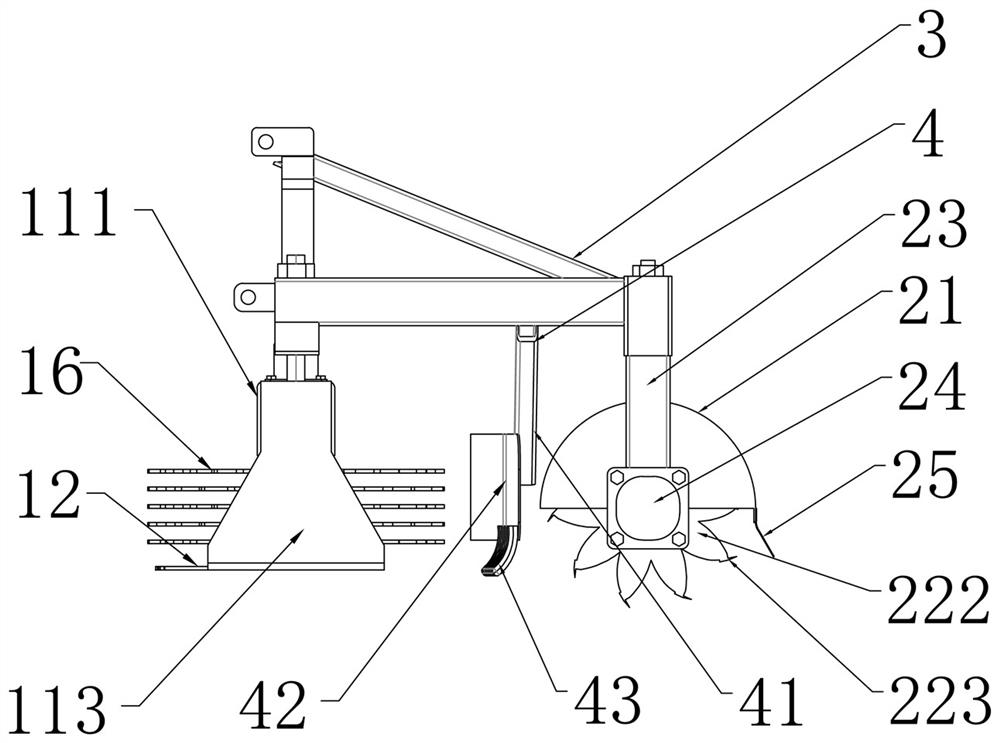

[0033] Embodiment 1: The stubble grinder of this embodiment is installed on the rear suspension of the tractor and is driven by the forward movement of the tractor to move forward, and is controlled to move up and down by the rear suspension of the tractor. Such as figure 1 As shown, the stubble grinder includes a suspension frame 3, which is fixedly installed on the rear suspension of the tractor, and can connect the hydraulic motor with the hydraulic oil tank device at the same time; the suspension frame is welded by a plurality of square tubes. Under the premise of meeting the requirements of use, choose a thin and small square tube as much as possible, which can effectively reduce the weight of the whole machine, thereby reducing energy consumption; a longitudinal crushing header is installed at the position below the front end of the suspension frame through the buffer mechanism 5 ,Such as figure 2 and Figure 6 As shown, the buffer mechanism 5 includes a buffer frame ...

Embodiment 2

[0041] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be described in detail. The difference is that in order to improve the crushing efficiency of the longitudinal crushing header, this embodiment is based on Embodiment 1. The front end of the front end is uniformly provided with sawtooth 18, which is helpful for the cutting table fixing plate to level the land while helping the saw blade to crush and effectively prevent the straw from clogging the saw blade during the advancing process; There are comb teeth 19 with different heights, and the comb teeth are located between adjacent saw blade groups and do not affect the opposite cutting of adjacent saw blades, which is beneficial to combing the stubble and facilitates the rotary cutting and crushing of the saw blades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com