Ceramic raw material stirring device

A technology of a stirring device and ceramic raw materials, which is applied in the field of ceramic product production, can solve the problems of quality influence of finished ceramics, inability to remove iron impurities, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

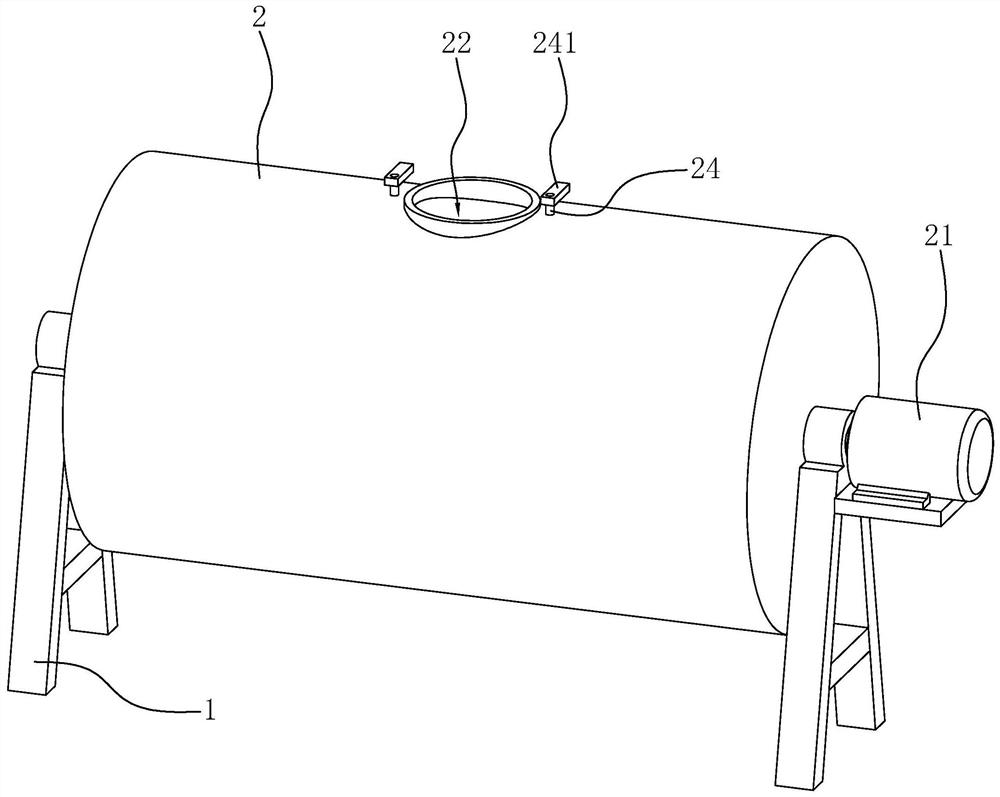

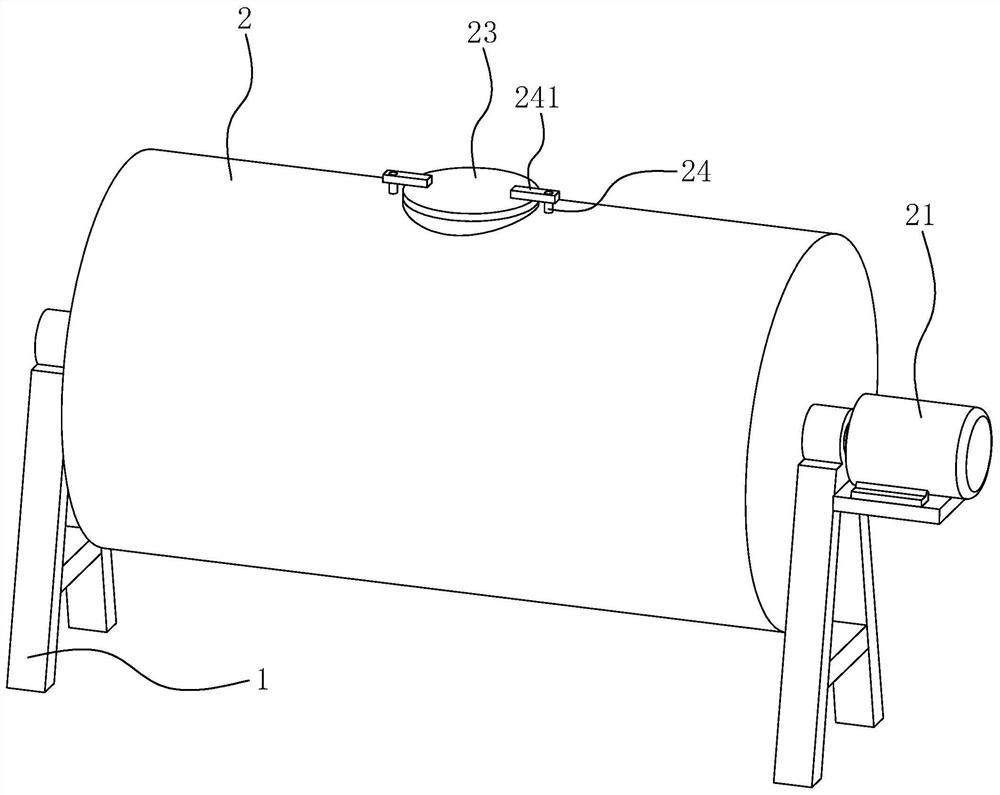

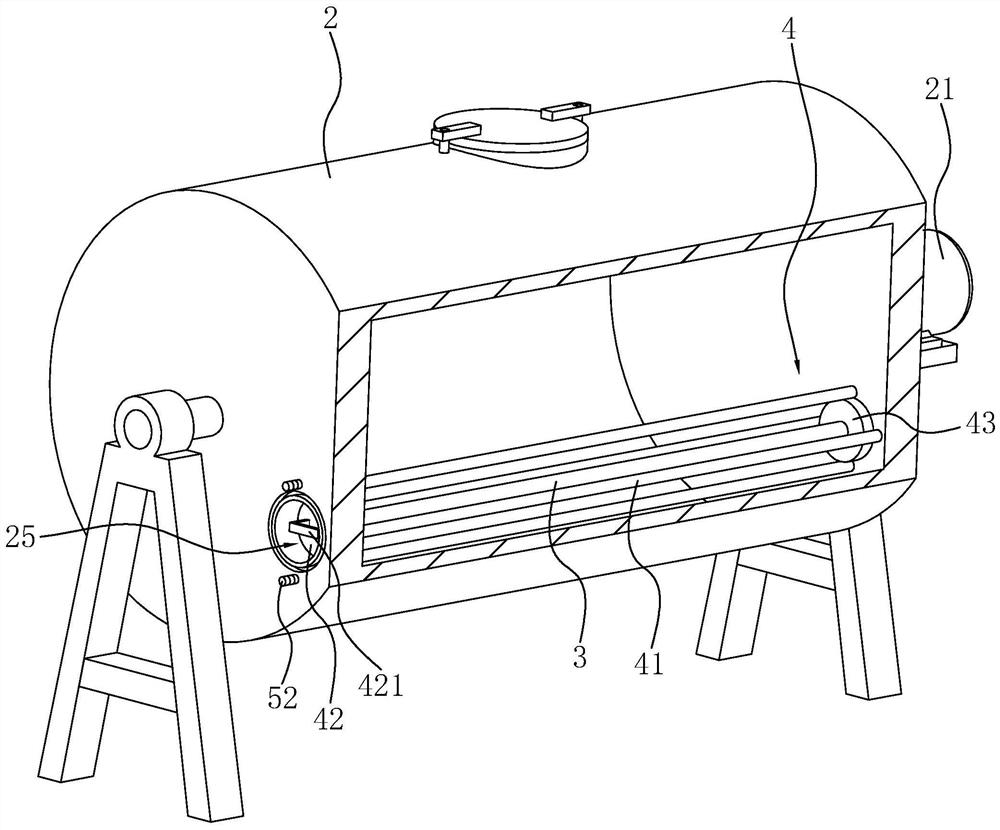

[0037] Embodiment one: if image 3 As shown, it is a ceramic raw material stirring device disclosed in the present invention, which includes a first connecting hole 25 provided at an eccentric position on a side of the mixing barrel body 2 away from the motor 21, and the first connecting hole 25 communicates with the inside of the mixing barrel body 2. . A magnet bar 3 passes through the first connection hole 25 , and the magnet bar 3 is inserted into the inside of the mixing tank body 2 and connected to the inner wall of the mixing tank body 2 through the connecting mechanism 4 .

[0038] Such as image 3 and Figure 4 As shown, the side of the mixing tank body 2 provided with the first connection hole 25 is connected with an end cover 51 through the dismounting mechanism 5. When the magnet bar 3 is inserted into the inside of the mixing tank body 2, the end cover 51 covers the first connection hole 25 (refer to Figure 5 ).

[0039] When the ceramic raw materials need t...

Embodiment 2

[0051] Embodiment two: a kind of ceramic raw material stirring device, such as Figure 6 and Figure 7 As shown, the difference from Embodiment 1 is that the first connecting block 42 is provided with a second connecting hole 422 passing through the first connecting block 42 along the axis direction of the magnet bar 3, and the shape of the second connecting hole 422 is arc-shaped. , the middle portion of the second connecting hole 422 is depressed downward.

[0052] A receiving plate 423 is inserted into the second connecting hole 422 , and the cross-sectional shape of the receiving plate 423 is the same as that of the second connecting hole 422 . The receiving plate 423 extends away from the side of the first connecting block 42 to close to the second connecting block 43 , and the side of the second connecting block 43 close to the receiving plate 423 is provided with a connecting groove 431 having the same shape as the second connecting hole 422 . When the receiving plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com