Wide and thick sheet all hydraulic multi-roller temperature straightening machine HGC hydraulic cylinder dismounting and mounting method

A disassembly method and hydraulic cylinder technology, applied in the direction of metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of high risk, small operating space, difficult operation, etc., to reduce risk and mechanical damage, avoid distortion Pull obliquely to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

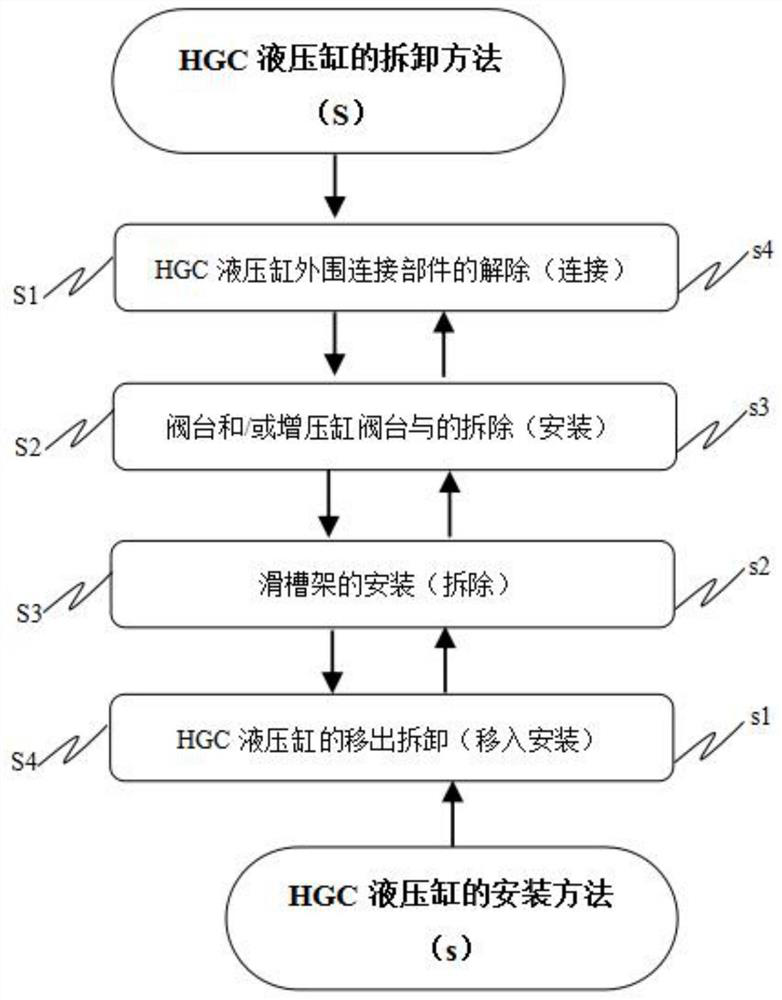

[0071] This embodiment provides a method for disassembling and assembling the HGC hydraulic cylinder of a full-hydraulic multi-roll warm straightening machine for wide and thick plates.

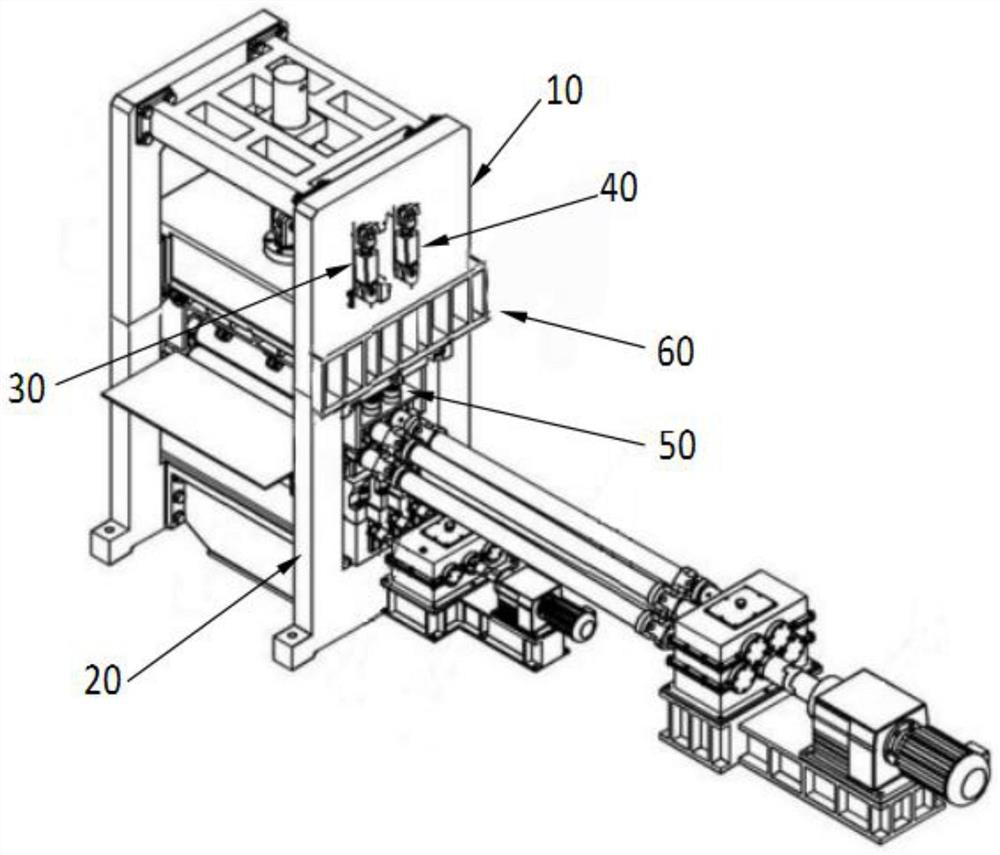

[0072] Such as figure 1 The structural schematic diagram of the wide and thick plate full hydraulic multi-roll warm straightening machine in the disassembly method of the HGC hydraulic cylinder of the wide and thick plate full hydraulic multi-roll warm straightening machine provided by the embodiment of the present invention is as follows:

[0073] In this embodiment, the full-hydraulic multi-roll temperature straightening machine for wide and thick plates is used to eliminate defects such as floating or wavy bending of wide and thick steel plates caused by uneven deformation due to uneven temperature after the wide and thick steel plates pass through the rolling mill or rapid cooling ,include:

[0074] Two upper beams 10 set up side by side and the pressing frame 20 installed at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com